Labeling Accuracy and Quality Stability

Why Precision Matters Most

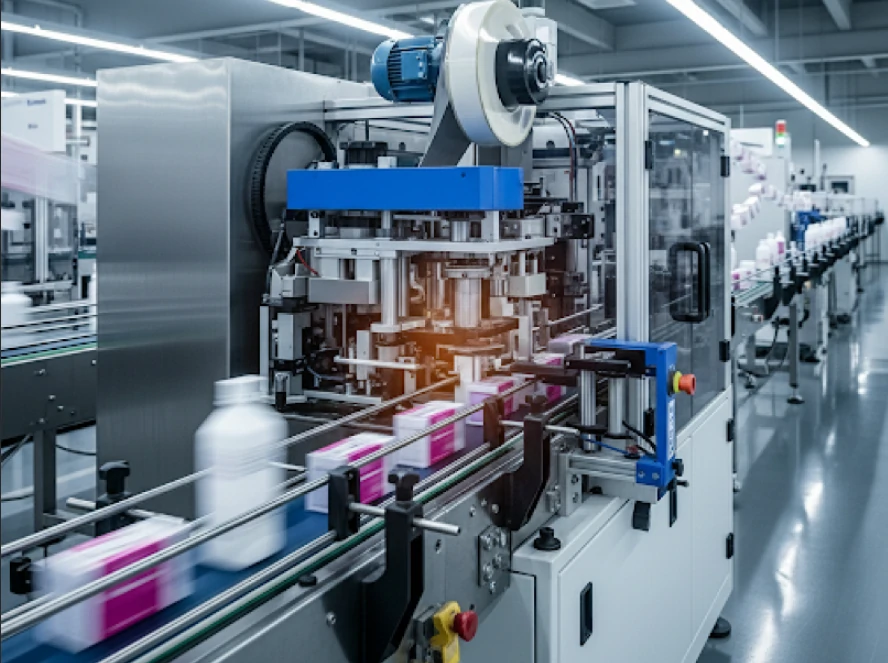

Labeling accuracy is the cornerstone of a labeling machine’s performance. Misaligned, bubbled, or wrinkled labels can harm a product’s appearance and brand image, particularly in the pharmaceutical and food industries.

Common Customer Questions:

- What’s the labeling accuracy? (e.g., ±0.5mm or ±1mm?)

- Does accuracy drop at high speeds?

- How do you ensure consistent label placement during long runs?

- How are bubbles prevented with transparent labels?

Machines equipped with high-precision sensors and bubble-elimination technology can achieve accuracy as tight as ±0.1mm, even at speeds of 300 units per minute. Look for technical specification sheets and request accuracy test reports when evaluating options

Versatility and Changeover Efficiency

Can One Machine Handle Multiple Products?

Modern factories often produce a variety of products, so equipment must support diverse shapes and sizes while enabling quick changeovers to minimize downtime.

Common Customer Questions:

How long does it take to switch between product specifications?

- Are specialized tools required?

- What product types are supported? (e.g., round bottles, square bottles, flat bottles, boxes, or ampoules)

- What’s the range of supported product dimensions?

Top-tier labeling machines accommodate products with diameters of 10-150mm and heights of 25-300mm, with changeovers taking just 5-10 minutes. Modular designs and tool-free adjustments allow even novice operators to adapt quickly, enhancing production flexibility.

Production Efficiency and Labeling Speed

Matching Your Line’s Needs

Labeling speed directly impacts production efficiency, and customers want machines that integrate seamlessly with existing lines.

Common Customer Questions

- What’s the maximum stable labeling speed?

- Can it match the speed of our filling or capping equipment?

- Does it support variable speed control?

High-end labeling machines achieve speeds of 30-300 units per minute with stepless speed adjustment, ensuring compatibility with various production lines. Frequency-controlled motors enable smooth transitions from low to high speeds, boosting capacity by up to 20%.

Reliability and Maintenance

How Durable Is the Equipment?

Equipment downtime leads to costly production halts, making reliability and ease of maintenance critical considerations.

Common Customer Questions:

- What brands are used for core components (e.g., motors, PLCs, sensors)?

- What’s the mean time between failures (MTBF)?

- How complex is routine maintenance? How quick is spare parts delivery?

Machines with trusted components from brands like Siemens can achieve an MTBF of 10,000 hours. Modular designs simplify part replacement, and spare parts are typically available within a week. Routine maintenance involves only cleaning and lubrication, keeping operations hassle-free.

Ease of Use and Operator Requirements

How Easy Is It to Operate?

A user-friendly interface reduces training costs and operator errors.

Common Customer Questions:

- How long does it take to train new operators?

- Are there clear alerts and troubleshooting guides for faults?

- Does it have a touchscreen interface? Is it available in English?

Modern labeling machines feature intuitive touchscreens, often in English, resembling smartphone interfaces. New operators can be trained in 1-2 hours. Built-in smart alerts and self-diagnostic systems provide clear fault guidance, minimizing errors.

Integration with Existing Lines

Seamless Compatibility?

Labeling machines are often part of a larger packaging line, so integration with other equipment (e.g., bottle unscramblers or printers) is vital.

Common Customer Questions:

- Are infeed/outfeed directions and heights adjustable?

- Does it offer signal interfaces for coordinated control?

- How much floor space does it require?

Adjustable machines with standard PLC signal interfaces and compact footprints (1-2 square meters) fit easily into existing layouts. Proper integration can boost overall line efficiency by 20% or more.

Total Cost of Ownership and ROI

What’s the Long-Term Value?

Customers care about more than just the initial price—they want to understand the total cost of ownership (TCO) and return on investment (ROI).

Common Customer Questions:

- What’s included in the quote? (e.g., shipping, installation, training)

- What’s the energy consumption?

- How soon can the investment be recouped?

Transparent quotes should cover installation and training, with energy consumption as low as 1-2kW/h. By saving 2-3 workers and reducing defect rates by 5%, ROI is typically achieved within 6-12 months. Use a TCO calculator to evaluate long-term value.

After-Sales Service and Support

How Responsive Is the Provider?

Timely support is critical for minimizing downtime and ensuring peace of mind.

Common Customer Questions:

- What’s the warranty period and coverage?

- How quickly do you respond to faults or dispatch technicians?

- Is remote diagnostics support available?

Look for providers offering a 2-year warranty, 24-hour response times, and on-site service within 48 hours, plus remote diagnostics and free training for reliable operation.

Customization for Specific Applications

Can It Meet Unique Needs?

Standard machines may not address all scenarios, making customization a key factor.

Common Customer Questions:

- Can you customize for unique product shapes?

- Is integration with printers or vision systems possible?

- Does it comply with GMP standards?

Manufacturers with robust R&D capabilities can tailor solutions for unique shapes and integrate systems like printers or vision inspection. Equipment should meet GMP/FDA standards for pharmaceutical applications.

Case Studies and Industry Reputation

Case Studies and Industry Reputation

Real-world examples build customer confidence.

Common Customer Questions:

- Are there case studies from our industry?

- Can you provide videos of the machine in action?

- What’s your market reputation and experience?

Providers serving pharmaceutical and food industries, with operational videos and a decade of experience, demonstrate reliability and leadership in the market.

Industry Compliance and Certifications

Does It Meet Standards?

Compliance is non-negotiable in pharmaceuticals and packaging.

Common Customer Questions:

- Does it meet GMP or FDA standards?

- How is contamination or cross-contamination prevented?

- Are third-party certification reports available?

Machines certified to CE, ISO, GMP, and FDA standards, using stainless steel to prevent contamination, and backed by third-party reports, ensure regulatory compliance.

Why Choose AUTmachine?

AUTmachine is your trusted partner for automatic labeling solutions:

- Certified Quality: CE, ISO, and multiple patents ensure top-tier performance.

- Robust Manufacturing: 5,000 sqm factory, 10 production lines, and 200 units in stock for fast delivery.

- Wide Applications: Supports round bottles, flat bottles, boxes, and ampoules.

- Proven Expertise: 10 R&D engineers with 20 years of industry experience.

- Exceptional Support: 24/7 customer service with remote and on-site assistance.

Choosing an AUTmachine labeling machine means investing in efficiency, precision, and reliability. Our machines replace 3-6 workers, slashing costs and boosting competitiveness. Visit https://autmachine.com/ now to request a free sample test or custom solution! Contact the AUTmachine team to learn how we can design, build, and install your solution in just 15 days, revolutionizing your production line