Labeling is a critical step in packaging, especially for products that need to communicate brand, compliance, and product information clearly. This article will explore everything you need to know about cold glue labeling machines—from how they work, where they are used, what types are available, to how to choose the right one for your production line.

Whether you are a beginner or a packaging engineer, this guide will give you a clear understanding of cold glue labeling technology.

What Is a Cold Glue Labeling Machine?

A cold glue labeling machine is a piece of equipment that applies labels to containers using water-based adhesive (also known as cold glue). The term “cold” refers to the fact that the glue does not need to be heated during the application process. Unlike hot melt glue labeling machine, cold glue remains in liquid form at room temperature.

The glue used is typically a starch-based or casein adhesive, which dries by evaporation. These glues are eco-friendly, inexpensive, and effective for paper labels on glass, metal, and some plastic containers. Cold glue labeling machines are often used in industries such as food and beverage, cosmetics, chemicals, and pharmaceuticals.

How Does a Cold Glue Labeling Machine Work?

The process of cold glue labeling involves several steps. Each step is handled by a specific part of the machine. The basic operation includes the following stages:

Label Feeding

The machine starts by picking up labels from a magazine or stack. The label magazine holds a large number of cut paper labels and feeds them into the machine one by one. This process ensures continuous operation without frequent reloading.

Glue Application

Once the machine picks up a label, it moves it toward the glue roller. The glue roller rotates inside a glue tank and picks up a thin layer of adhesive on its surface. A scraper blade removes any excess glue to make sure the glue is evenly spread. Then, the glue is transferred onto the label.

Label Transfer

After the glue has been applied, a transfer roller or vacuum cylinder moves the label toward the container. The machine synchronizes this step with the movement of the container to ensure proper alignment.

Label Application

The container moves along a conveyor belt and is held in place by guides or a rotating station. When the glued label reaches the container, the machine presses it against the surface. A brush or sponge roller smooths the label to remove air bubbles and improve adhesion.

Final Positioning and Drying

In the last stage, the machine checks the position of the label. If the label is not placed correctly, the machine may reject the product or stop the line. Afterward, the glue dries naturally as the product continues down the production line.

Key Components of a Cold Glue Labeling Machine

Understanding the parts of the machine can help users operate, maintain, and troubleshoot it effectively.

- Label Magazine: This is the part of the machine that holds the stack of pre-cut labels. The magazine must be loaded manually or automatically depending on the system.

- Glue Roller / Anilox Roller: This roller picks up glue from a glue tank and applies it to the back side of the label. The surface of the roller controls how much glue is applied.

- Vacuum Drum or Pad: The vacuum drum holds the label using suction until it is transferred onto the container.

- Container Conveyor: A belt or chain conveyor carries the containers through the machine at a consistent speed.

- Labeling Station: This is the zone where the glued label meets the container. It includes positioning guides, pressing rollers, and sensors to ensure perfect label placement.

- Drive System: Motors and gears power the movement of various parts of the machine.

- Control Panel: Operators use the control panel to adjust machine settings, speed, and label positioning.

What Types of Cold Glue Labeling Machines Exist?

There are several types of cold glue labeling machines. The right type for your factory depends on your product, label material, and production speed.

Rotary Cold Glue Labeling Machine

Rotary machines are designed for high-speed applications. The containers move around a rotating carousel, and each labeling station works in synchronization to apply labels quickly and accurately. This type is ideal for beverage bottles, especially glass bottles used for beer, wine, or soft drinks.

Linear Cold Glue Labeling Machine

Linear machines operate in a straight line and are suitable for medium-speed production. They are easier to operate and maintain than rotary machines. Linear machines are commonly used in industries with lower production volumes or more varied container types.

Semi-Automatic Cold Glue Labeling Machine

Semi-automatic machines require some manual input. An operator places the container on a platform, and the machine applies the label. This type is best for small businesses, test batches, or products with unique shapes that require more flexible handling.

Custom or Modular Systems

For industries with special labeling needs, such as pharmaceuticals or cosmetics, manufacturers often design custom solutions that combine cold glue units with inspection systems, alignment tools, or secondary labeling units.

Cost Considerations of Cold Glue Labeling Machines

A basic semi-automatic cold glue labeling machine starts at around USD 5,000. A high-speed fully automatic unit may cost USD 100,000 or more. A buyer must add the cost of glue, solvent, and spare parts. A factory should budget for operator training and preventive maintenance. A production lead should compare total cost of ownership over five years. A buyer should ask for lease or rental options for short-term projects. A plant can negotiate service agreements to include parts and labor.

Advantages of Cold Glue Labeling Machines

Many factories choose cold glue systems for good reasons. Here are the top benefits:

- Cold glue is significantly cheaper than hot melt adhesives or pressure-sensitive labels. This makes cold glue systems ideal for high-volume products with thin profit margins.

- Water-based adhesives are more sustainable and safer for workers. They also reduce chemical waste compared to solvent-based options.

- Cold glue creates a strong and lasting bond when paired with paper labels and rigid containers, such as glass bottles or metal cans.

- Rotary cold glue machines can label hundreds of containers per minute. This is essential for large-scale production environments.

- Cold glue machines can handle labels of various shapes and sizes, including wraparound, front-and-back, and neck labels.

Challenges and Limitations

No machine is perfect. Cold glue labeling machines also come with challenges that users need to manage.

- Cold glue works best with paper labels. Plastic or synthetic labels may not bond well unless specially treated.

- Since glue is water-based, it can dry out and clog parts if not cleaned regularly. Daily maintenance is necessary to avoid downtime.

- Cold glue machines may take longer to set up compared to pressure-sensitive systems. Fine-tuning label position and glue volume can be time-consuming.

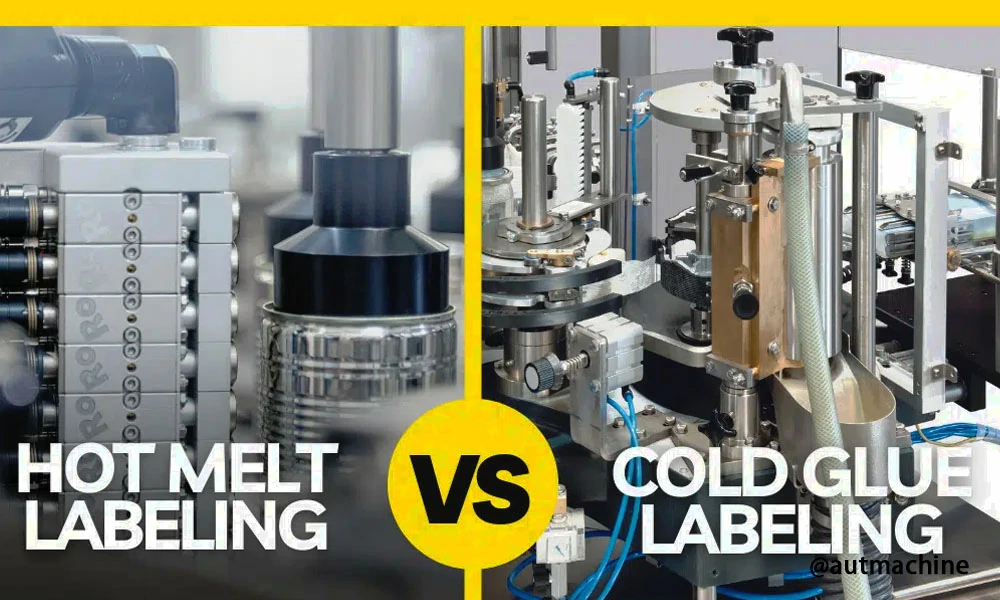

Cold Glue vs. Other Labeling Methods

Choosing between cold glue and other methods depends on your product, label type, and budget.

| Feature | Cold Glue | Hot Melt | Pressure-Sensitive |

|---|---|---|---|

| Adhesive Type | Water-based | Melted resin | Pre-applied sticker |

| Cost | Low | Medium | High |

| Speed | High | Very high | Medium |

| Label Types | Paper | Paper, film | Paper, film |

| Container Shapes | Mostly round | All shapes | All shapes |

| Maintenance | Medium | High | Low |

Cold glue is ideal for traditional industries like beer, canned foods, and low-margin products where cost and speed matter more than label material flexibility.

Is Cold Glue Labeling Right for You?

The answer depends on your product type, production speed, and label material. If you use paper labels and your containers are rigid (especially glass), then cold glue labeling is likely the best option. It is ideal for large production runs where cost efficiency matters. On the other hand, if you deal with custom shapes, synthetic labels, or short runs, pressure-sensitive systems might offer more flexibility.

Where Are Cold Glue Labeling Machines Used?

Cold glue labeling machines are widely used across industries:

- Beverage Industry: For labeling glass bottles of beer, wine, or soft drinks.

- Food Industry: For jars, tins, and cans of sauces, jams, or preserves.

- Pharmaceuticals: For applying wrap-around labels on pill bottles.

- Cosmetics: For labeling glass perfume bottles or lotion jars.

- Household Goods: For applying labels to cleaning product containers.

Factories that prioritize durability, reliability, and cost-effectiveness usually prefer cold glue solutions.

Maintenance of Cold Glue Labeling Machines

Proper maintenance keeps a cold glue labeling machine running smoothly and increases its lifespan.

Routine Maintenance Tasks:

- Clean Glue Roller Daily: Dried glue can block the roller and reduce glue transfer. Clean the roller after every shift.

- Check Conveyor Belts: Make sure the belts are aligned and free of dust or oil that could affect grip.

- Lubricate Moving Parts: Apply machine oil to gears, bearings, and joints as needed.

- Inspect Sensors: Sensors must be clean and responsive for accurate label placement.

- Drain Glue Tank: Replace glue daily or weekly to prevent contamination.

Common Issues and Solutions:

- Label Misalignment: Adjust container guides or check if the label magazine is feeding labels properly.

- Glue Not Sticking: Check glue quality or clean the glue roller.

- Label Wrinkles: Adjust the pressure of the pressing rollers.

- Machine Stops Frequently: Inspect power connections, safety doors, or sensor functionality.

AUTmachine: A Trusted Manufacturer of Labeling Solutions

If you’re looking for a reliable automatic labeling machine, AUTmachine is a trusted name in the industry. Based in China, AUTmachine specializes in designing and manufacturing advanced gluing machines for labeling, bookbinding, packaging, and more. The company offers:

- Custom configurations for various containers

- Responsive technical support

- Competitive pricing for global markets

AUTmachine is labeling machines are already helping factories in food, beverage, cosmetic, and industrial sectors achieve faster labeling with reduced costs.

Conclusion

Cold glue labeling machines continue to be a trusted tool in many packaging lines. They are affordable, reliable, and suitable for eco-conscious brands. By understanding how they work and what features matter most, you can choose the right machine for your business and keep your labeling process running smoothly.

When choosing a machine, make sure to consider your production needs, container shapes, label materials, and maintenance requirements. With proper care and the right machine—like those offered by AUTmachine—you can keep your labeling process running smoothly for years to come.

FAQ

Cold glue refers to a water-based adhesive that stays fluid at room temperature. Cold glue requires no heating elements.

A cold glue machine uses water-based adhesive, while a hot-melt machine uses heated solid glue sticks. A cold glue system runs at room temperature, and a hot-melt system runs at elevated temperatures.

Yes. A quick-change station design lets an operator swap rollers and adjust sensors in minutes.

Yes. A precision glue application system uses minimal glue to avoid show-through or glue spots.