India has emerged as a major hub for labeling machine manufacturing by 2025. Companies in India now offer solutions that power everything from pharmaceuticals to food and beverage lines. This growth has been fueled by rising industrial automation, the need for faster production speeds, and stricter regulations on traceability and branding.

As a result, labeling machine manufacturers have stepped up to offer machines that balance high throughput, precision, and ease of use. Numerous factors contribute to a company’s success in this landscape, such as its research and development efforts, on-site technical support, customizable designs, and compliance with international standards

India’s Top 10 Labeling Machine Manufacturers (2025)

Labeling machines play a critical role in India’s booming packaging and manufacturing industries. As consumer demand grows and regulations become more stringent, accurate and efficient labeling systems are essential. In 2025, these ten companies stand out as leaders in innovation, quality, and service:

- AUTmachine

- Maharshi Udyog

- Jaisat Packaging

- Worldpack Labelling Machines

- LabeMachine

- Herma India

- Interpack Technologies

- Multipack Machinery

- Indian Packaging Corporation

- Next Packaging Machinery Pvt. Ltd.

| Company | Key Products | Strengths | Main Industries |

|---|---|---|---|

| AUTmachine | Auto & semi-auto labelers, tubes, cans, boxes | Patents, CE/ISO, global OEM, fast delivery | Pharma, Food, Electronics |

| Maharshi Udyog | Wrap-around, hot-melt, dual labelers | 40+ yrs experience, global reach | Food, Pharma, Cosmetics |

| Jaisat Packaging | High-speed inline labelers | Modular design, long-term support | Pharma, Cosmetics |

| Worldpack Labelling | Self-adhesive, wrap-around | ISO certified, spare part hubs | Beverage, Pharma |

| LabeMachine | Wire & bottle labeling | Easy integration, R&D partnerships | Cable, Pharma, Food |

| Herma India | IoT-enabled smart labelers | Real-time error check, German tech | Pharma, High-speed lines |

| Interpack Technologies | Self-adhesive, vial labelers | Rugged build, maintenance portal | Chemicals, FMCG |

| Multipack Machinery | Wrap-around, ampoule labelers | Clean design, validation support | Food, Pharma |

| Indian Packaging Corp. | Labeling + filling/sealing lines | End-to-end setup, flexible payment | SMEs, General Packaging |

| Next Packaging Pvt. Ltd. | Bottle labelers, batch coders | Plug-and-play, in-house service | SMEs, General Industry |

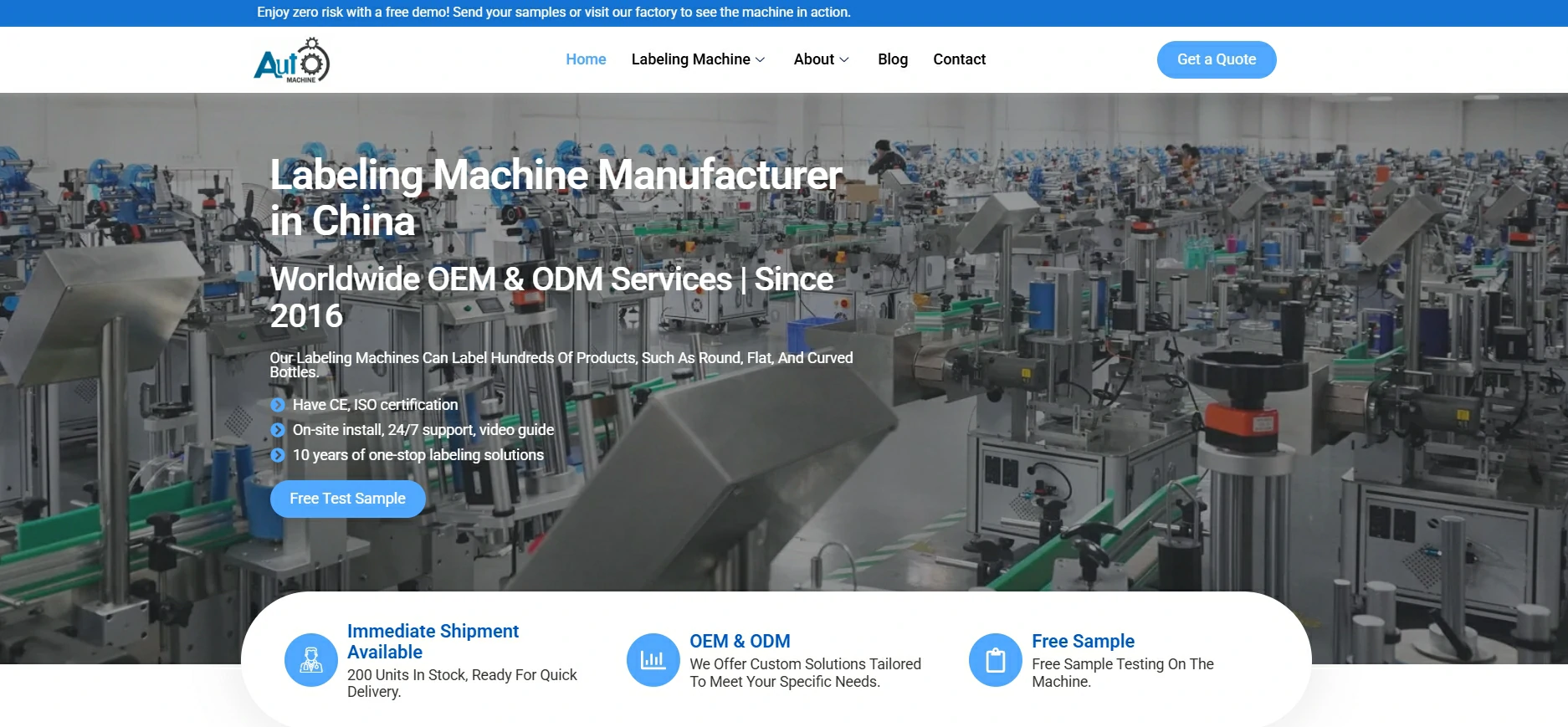

1. AUTmachine

AUTmachine has cemented its reputation as a dedicated innovator in the labeling industry. The company started operations in 2016 and focuses on automated labeling systems that serve flat surfaces, bottles, cans, and more. AUTmachine’s team brings together mechanical designers, electronic engineers, and software developers who work under a shared culture of quality and collaboration.

Team and Capabilities

AUTmachine’s team includes experts in mechanical design, electronics, and software engineering. The company values teamwork and provides growth opportunities to each member Autmachine.

Factory, Certifications & Patents

Their 5,000 m² plant includes 10 production lines and houses 200 units in stock, supported by over 100 skilled engineers . AUTmachine holds CE and ISO certifications and has earned several patents, including those covering adjustable head split labelers, high‑accuracy e‑cigarette tube labelers, and front-and-rear roll-on machines.

Product Range & Industries

AUTmachine offers a wide array of machines—fully autmatic labeling machine or semi-automatic labeling machine, suited for bottles (vertical/horizontal), flat surfaces, cans, and boxes. They also support corner, bottom, and hot-glue labeling. Industries served include food and beverage, cosmetics, pharmaceuticals, daily chemicals, FMCG, and electronics.

Key Features

- Accuracy & Speed: Labeling precision ranges from ±0.1 mm to ±1 mm, and speed can reach 300 pcs/min on certain models.

- Integration & Flexibility: Machines feature PLC touchscreen controls and optional printers for batch or date codes. They integrate smoothly into existing lines.

- Support & Customization: Free sample tests, OEM/ODM services, remote and onsite support, plus one‑year warranties demonstrate customer-first values.

Why AUTmachine Stands Out

AUTmachine combines well-documented technical prowess (patents and certifications), diverse products, strong customization, and fast delivery (stock ready to ship). Though headquartered in China, its global OEM/ODM model makes it a strong contender for Indian businesses seeking dependable labeling solutions.

2. Maharshi Udyog

Maharshi Udyog traces its roots back over forty years, and it has grown from a small local business into a global name in labeling machines. The company offers a wide range of products, including wrap-around labelers, front-and-back labelers, and hot-melt glue labelers. Maharshi invests heavily in research and development, which allows it to introduce incremental improvements and entirely new models each year. As a result, its machines consistently meet evolving regulatory and industry standards.

Maharshi Udyog serves sectors such as food and beverages, pharmaceuticals, cosmetics, and chemicals. The company’s top-and-bottom labelers, for example, can apply two labels in a single pass, which reduces cycle times and minimizes human error. Because Maharshi operates a global distribution network, it can ship machines and spare parts to distant markets within days. Furthermore, Maharshi’s facilities include in-house calibration labs and state-of-the-art test rigs, which ensure that every machine meets precise specifications before it leaves the plant.

3. Jaisat Packaging

Jaisat Packaging has built its reputation on high-performance labeling machines tailored to the pharmaceutical, food, and cosmetic industries. The company emphasizes reliability and ease of maintenance, which has made it a preferred partner for large production lines. Jaisat’s inline labeling systems can handle speeds of up to 450 products per minute, and the modular design allows quick changeovers between product formats.

The organization supports clients with turnkey installation services, operator training, and preventive-maintenance contracts. Therefore, it often remains involved in a customer’s production facility for years after the initial sale. Jaisat Packaging also pursues continuous improvement through customer feedback loops and field audits. Because of this approach, it can roll out software updates remotely and recommend hardware upgrades that extend machine lifespans.

4. Worldpack Labelling Machines

Worldpack Labelling Machines, headquartered in Navi Mumbai, prides itself on offering one of the broadest catalogs of labeling equipment in India. The company produces self-adhesive labelers, hot-melt glue labelers, and wrap-around labelers for containers ranging from vials to kegs. Worldpack’s team focuses on modular construction so that customers can adjust machine configurations without lengthy downtimes.

Because Worldpack operates its own engineering and assembly lines, it can maintain consistent quality control at every stage. The company’s commitment to best practices has earned it ISO certification, and it partners with global firms for precision components. Moreover, Worldpack provides robust after-sales service, which includes on-site repairs, remote diagnostics, and stocked regional warehouses for critical spare parts.

5. LabeMachine

LabeMachine began operations in 1998 and has gradually evolved into a comprehensive automation equipment provider. The company manufactures wire-labeling machines, bottle-labeling machines, and corner-wrap labelers, among other offerings. LabeMachine’s products stand out because of their intuitive control interfaces and ability to integrate smoothly with existing production lines.

The firm invests in ongoing staff training for its engineers and technicians, which enables quick troubleshooting on site. Therefore, customers often cite LabeMachine’s customer support as a major reason for repeat business. In addition, LabeMachine maintains an R&D unit that collaborates with domestic universities, driving research into new materials and label-feed mechanisms. Because of these partnerships, the company can field test prototypes with real-world users before full-scale production.

6. Herma India

Herma, a global labeling-machine specialist, has maintained an Indian subsidiary to serve local clients with tailored solutions. The company focuses on digital labeling and smart labeling technologies that incorporate IoT sensors for real-time quality checks. Herma India’s machines can detect mis-applied labels and automatically reject incorrect products, thus reducing material waste and boosting line efficiency.

Furthermore, Herma India leverages its parent company’s global engineering centers to develop next-generation labeling heads and advanced vision systems. As a result, the Indian operation can provide both international standard machines and locally adapted variants that match Indian voltage and footprint requirements. Herma’s local service network ensures rapid response times, typically within 24 hours, which is crucial for high-speed pharmaceutical lines.

7. Interpack Technologies

Interpack Technologies, based in Navi Mumbai, has earned trust as a specialist in sticker and sensitive labeling machines. The company’s product line covers self-adhesive labelers for bottles, vials, and wires. Interpack’s machines are noted for their sturdy frames and precise label placement, even at high speeds. Because the firm maintains its own sheet-metal and assembly workshops, it can rapidly prototype specials and custom solutions for niche applications.

The company also offers preventive-maintenance agreements and an online portal that tracks a machine’s health metrics. Therefore, clients can schedule maintenance when throughput is low, which avoids unplanned stoppages. Interpack Technologies has a dedicated R&D team that works on label-dispensing algorithms and anti-jam sensors, which ensures that the machines handle a wide range of label materials without snags.

8. Multipack Machinery

Multipack Machinery of Ahmedabad has made its mark by offering wrap-around bottle labelers, ampoule sticker labelers, and front-and-back labelers with servo drives. The company’s machines are engineered for ease of cleaning, which is essential in pharmaceutical and food environments. Multipack uses hygienic design principles—such as stainless-steel conveyors and sealed motors—so that clients can perform thorough washdowns without damaging the equipment.

In addition, Multipack provides on-site validation services for pharmaceutical customers, including IQ/OQ/PQ documentation. Therefore, clients in regulated industries find that Multipack machines help them meet audit requirements without extra consultancy costs. The company’s focus on compliance, combined with its regional spare-parts depots, makes it a go-to supplier for clients who must avoid unplanned production interruptions.

9. Indian Packaging Corporation

Indian Packaging Corporation, based in Mumbai, offers a broad portfolio that includes labelling machines, liquid-filling machines, and band sealers. The firm’s labeling systems are designed for small- to medium-scale operations, with output capacities ranging from 20 to 300 units per minute. Because the company also supplies conveyors and capping equipment, it can provide end-to-end filling and packaging lines.

Indian Packaging Corporation supports clients with turnkey project management, which covers factory layout, machine installation, and operator training. Therefore, first-time packaging line builders find that the company simplifies complex workflows. The firm’s flexible payment terms and in-house fabrication capabilities also help small businesses acquire robust labeling solutions without long lead times.

10. Next Packaging Machinery Pvt. Ltd.

Next Packaging, headquartered in Mumbai, specializes in batch-coding equipment, sealing machines, and bottle labeling systems. The company emphasizes user-friendly HMI screens and plug-and-play design, which reduces setup time. Because Next Packaging integrates its labeling heads with various makes of conveyors and printers, clients can replace older machines with minimal rewiring and floor changes.

Next Packaging also operates an in-house service center that performs routine preventive maintenance, retrofits, and upgrades. Therefore, clients appreciate that they can rely on a single point of contact for spares, repairs, and validation reports. The company’s focus on customer feedback drives its annual machine enhancements, ensuring that each new model addresses real-world pain points.

Conclusion

India’s labeling machine sector is no longer confined to basic automation. In 2025, the country’s leading manufacturers are offering high-speed, intelligent, and regulation-ready equipment. Each company listed here brings something different to the table—be it scale, customization, or smart tech.

AUTmachine, though a global player, is particularly well-positioned to support Indian industries thanks to its rapid delivery, extensive customization options, and strong engineering roots.

FAQ

AUTmachine stands out because it offers fully automated, patented labeling solutions. The firm combines mechanical, electronic, and software expertise to deliver customizable machines, and it supports customers with 24/7 technical service and free on‑site demos.

Most of the top ten serve sectors such as pharmaceuticals, food and beverages, cosmetics, and chemicals. Some, like Multipack Machinery, emphasize hygienic design for food and pharma, while others, like Jaisat Packaging, focus on ultra‑high‑speed pharmaceutical lines.

Common types include self-adhesive labelers, wrap‑around labelers, front‑and‑back labelers, hot‑melt glue labelers, and specialized tube or wire labelers. Several firms also offer smart or IoT‑enabled heads for real‑time error detection.

A new business should assess its production speed requirements, container types, regulatory needs, and budget. It then compares demo machines (where available), checks each supplier’s certification and service network, and reviews user testimonials to make an informed decision.