Labeling machines are essential tools across various industries, helping businesses apply labels quickly and accurately on products, packages, or containers. As demand for efficient, reliable labeling solutions grows, the United States has become home to some of the world’s leading manufacturers in this field. These companies combine advanced technology with practical design to meet diverse customer needs in sectors such as food and beverage, pharmaceuticals, cosmetics, and manufacturing.

Why Labeling Machines Matter

Labeling machines speed up the process of applying information to products. This information might include branding, ingredients, barcodes, batch numbers, or regulatory details. Manual labeling is time-consuming and prone to errors, which is why automated labeling machines have become critical for large-scale production.

With increasing product variety and regulatory standards, manufacturers require labeling machines that are flexible, easy to use, and precise. The best labeling machine makers offer equipment that can handle different container shapes and sizes, label types, and production speeds. Their machines also aim to reduce downtime, simplify maintenance, and improve overall efficiency.

Overview of the U.S. Labeling Machine Manufacturing Industry

The U.S. labeling machine industry is known for innovation, quality, and service. Many manufacturers in the country specialize in customizable solutions designed to fit unique production requirements. These companies typically offer a range of machines, from basic manual models to fully automated, integrated systems.

In 2025, the top manufacturers continue to focus on:

- Modular design for easy upgrades

- Compatibility with Industry 4.0 and smart factory systems

- Enhanced precision and speed capabilities

- Support and after-sales service excellence

Now, let’s take a closer look at some of the leading U.S. labeling machine manufacturers

| Manufacturer | Key Features & Strengths | Product Range | Industry Focus | Notable Innovations |

|---|---|---|---|---|

| Autmachine | Modular, durable, easy-to-maintain machines; strong customer support and training; smart tech integration | Semi-automatic and fully automatic labeling machines; supports pressure-sensitive, shrink sleeve, wrap-around labels | Food & Beverage, Pharmaceuticals, Cosmetics, Logistics | Touchscreens, IoT connectivity, real-time monitoring |

| Herma USA | Precision label placement; modular and configurable machines; sustainable solutions for recyclable materials | Pressure-sensitive labeling machines | Food, Pharmaceuticals, Cosmetics | Modular design, sustainability-focused |

| Label-Aire | Rugged, reliable; flexible for quick changeovers; custom engineering options | Pressure-sensitive, cut-and-stack, roll-fed label machines | Food Processing, Logistics, Industrial | Durable design for harsh environments |

| Accraply | High speed and precision; wide variety of labeling types; advanced automation and control | Rotary, wrap-around, pressure-sensitive labeling systems | Large-scale manufacturing in various sectors | Automation, Industry 4.0 integration |

| Allen Coding | Focus on coding combined with labeling; easy integration with packaging lines; reliable operation | Coding and labeling machines | Food, Beverage, Pharmaceutical | Efficient label application with coding |

1. AUTmachine

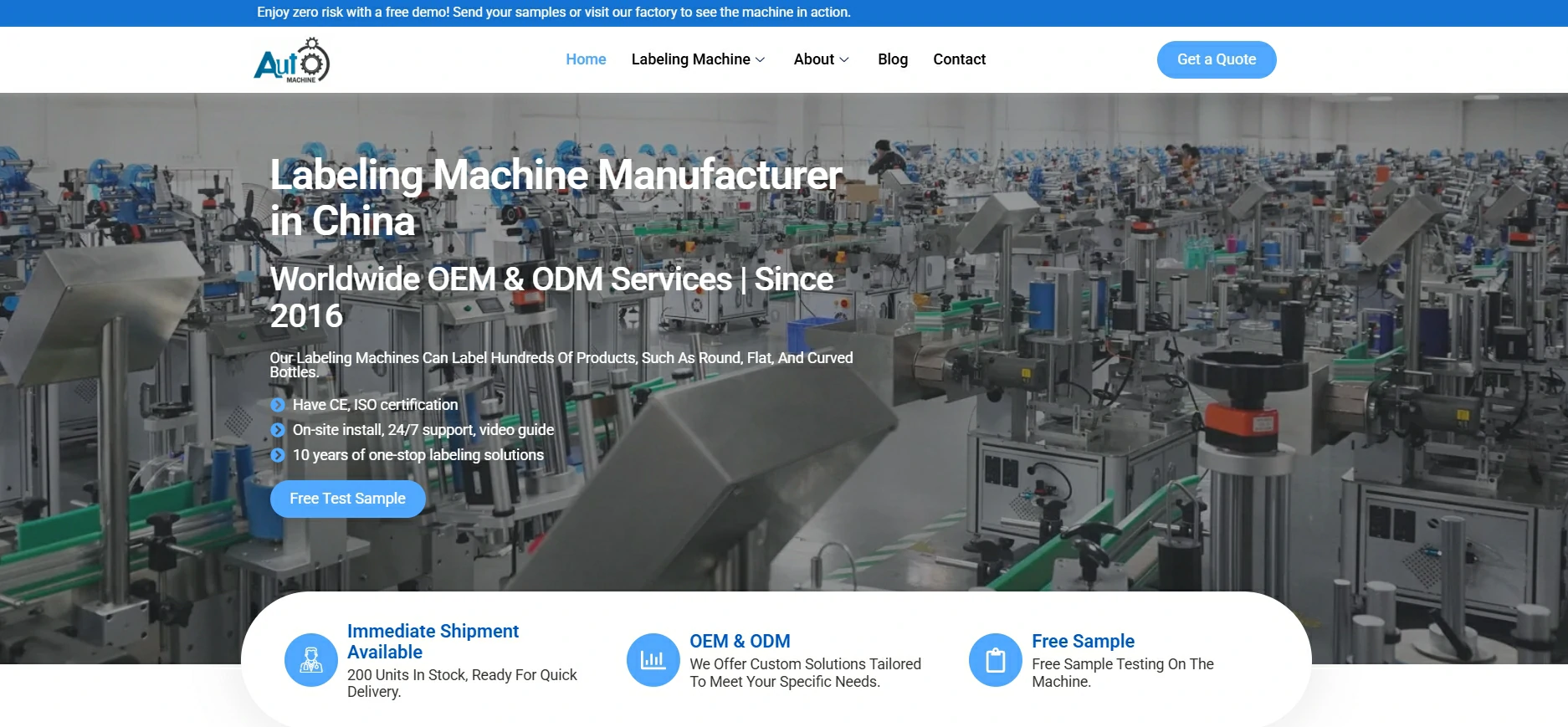

AUTmachine, originally based in Guandong, China, has rapidly emerged as a global player in automated labeling systems. Since 2016, the company has focused on high-precision labeling solutions for bottles, cans, tubes, boxes, and flat surfaces.

What sets AUTmachine apart is its deep engineering team—spanning mechanical, electrical, and software domains—and its ability to ship ready-made systems from a large 5,000 m² plant with 200+ machines in stock. Their machines include:

- Automatic front & back labelers

- Tube and e‑cigarette labelers (with patent-protected designs)

- Corner, bottom, and wrap-around systems

- Integration with batch/date printers and conveyors

Key Strengths:

- Labeling accuracy from ±0.1 mm

- Speeds up to 300 pcs/min

- CE and ISO certified

- Patented technologies and fast delivery

- U.S. clients can access remote diagnostics, free sample tests, and local OEM support

AUTmachine’s entry into the U.S. market brings global innovation at competitive pricing, making it a strong alternative to legacy American manufacturers.

2. Herma USA

Herma USA is a subsidiary of the global Herma Group, known worldwide for its labeling machines and systems. The company specializes in pressure-sensitive labeling solutions, offering a wide range of machines suited for small to high-volume production.

Herma’s machines emphasize precision and speed, with advanced control systems for exact label positioning. Their product line includes modular machines that can be configured for specific applications, including food packaging and pharmaceuticals. Herma also invests in sustainable solutions, such as machines compatible with recyclable materials.

3. Label-Aire

Label-Aire has been in the U.S. labeling market for decades, serving industries from food processing to logistics. The company is well-known for building rugged, reliable machines designed to handle harsh industrial environments.

Their labeling equipment supports pressure-sensitive, cut-and-stack, and roll-fed labels. Label-Aire machines are valued for their flexibility, allowing quick changeovers between different label sizes and types. The company also offers custom-engineered solutions to fit unique customer needs.

4. Accraply

Accraply, part of the Dover Corporation, provides advanced labeling and packaging solutions. Their machines include rotary, wrap-around, and pressure-sensitive labeling equipment. Accraply’s technology focuses on speed and precision, making them suitable for large-scale production lines.

The company incorporates automation and control systems that streamline operations and improve uptime. Accraply’s global reach and technical expertise allow it to serve diverse markets with tailored labeling systems.

5. Allen Coding

Allen Coding produces labeling machines designed mainly for coding and marking products with labels. Their focus is on efficient label application combined with product coding, essential for compliance and traceability.

Allen Coding’s machines support various label types and can integrate with other packaging and coding equipment. They emphasize reliability and ease of operation, suitable for food, beverage, and pharmaceutical sectors.

Trends Shaping the U.S. Labeling Machine Market in 2025

Several important trends influence the labeling machine industry today:

- Increased Automation: Manufacturers seek labeling machines that reduce manual labor and increase throughput. Fully automatic machines with integrated inspection systems are in high demand.

- Customization and Flexibility: Product variety requires machines that can easily adapt to different container shapes, sizes, and label types. Modular designs enable quick changeovers.

- Regulatory Compliance: As labeling regulations become more stringent, machines with barcode verification and traceability features help companies avoid costly errors.

- Sustainability: Many companies look for machines that minimize waste, use eco-friendly materials, and consume less energy.

- Smart Technology: Connectivity and IoT features allow real-time monitoring and predictive maintenance, reducing downtime and improving quality control.

Manufacturers like Autmachine align well with these trends by offering modular, easy-to-use, and smart labeling machines that support efficient and compliant production.

Autmachine in Detail: A Closer Look

Autmachine distinguishes itself through a customer-centric approach and technical innovation. The company’s history shows steady growth rooted in understanding user needs and industry trends. They offer labeling solutions for different container shapes, including round, square, and irregular forms.

One key feature of Autmachine machines is their modular design. This allows manufacturers to upgrade or customize parts of the machine without replacing the entire system. For instance, customers can add a printing module or change the labeling head to accommodate new label types.

Autmachine also emphasizes safety and compliance. Their machines meet U.S. and international standards for electrical and mechanical safety, an essential factor in regulated industries like pharmaceuticals and food processing.

Moreover, Autmachine invests in training programs for operators and maintenance teams. This ensures customers can maximize machine uptime and performance with minimal technical issues.

Looking forward, Autmachine plans to incorporate more data-driven features into their machines. This includes real-time performance monitoring and remote diagnostics, which align with the increasing trend toward Industry 4.0 technologies.

Conclusion

The labeling machine industry in the United States continues to evolve in response to growing production demands, technological advances, and sustainability concerns. Companies like Autmachine demonstrate how innovation and customer focus can build a strong market presence. With their combination of reliable engineering, flexible designs, and forward-looking features, these manufacturers provide essential tools for industries that rely on clear, accurate labeling.

FAQ

Autmachine offers flexible, modular, and affordable labeling solutions. Their machines combine user-friendly technology, high build quality, and strong customer support tailored for both small businesses and large manufacturers.

Yes, many modern labeling machines, including those from Autmachine, are designed to be highly adaptable. They allow quick changeovers to accommodate various container shapes, sizes, and label types.

Industries such as food and beverage, pharmaceuticals, cosmetics, chemicals, and logistics benefit greatly from reliable labeling machines that support high production standards.

Many manufacturers are now designing machines to minimize waste, reduce energy consumption, and work with eco-friendly materials, aligning with sustainability goals.