In 2025, the global label applicator market continues to grow steadily. Industry reports forecast a compound annual growth rate (CAGR) of approximately 5–6% over the next decade. For instance, analysts from Future Market Insights project a 6.0% CAGR in the first half of this decade, followed by a modest slowdown to 4.4% in the second half. Another study suggests a 4.3% CAGR through 2035, with total revenue reaching an estimated USD 9.18 billion. These figures illustrate a strong and sustained demand for automated labeling systems across various sectors.

The key drivers behind this growth include:

- Increasing demand for packaging automation, especially in food, beverage, pharmaceutical, and e-commerce industries.

- Regulatory requirements around accurate and traceable labeling.

- Advancements in labeling technologies, such as AI, IoT, smart sensors, and thermal printing.

- Rising adoption in high-volume packaging, particularly within the Asia-Pacific region.

Within this context, several companies distinguish themselves as market leaders in 2025.

What Are Label Applicators?

Before diving into the companies, it is important to understand what label applicators do. Label applicators are machines designed to apply labels on products, packages, or containers automatically. These machines are vital in industries like food and beverage, pharmaceuticals, cosmetics, and logistics. They improve the speed and accuracy of labeling, reduce human error, and help maintain consistent branding.

Leading Label Applicator Companies in 2025

Below is a detailed overview of the most prominent label applicator firms, including both established global players and emerging technical innovators.

Some of the most notable companies include:

- Autmachine

- Accraply (BW Labeling)

- EPI (ID Technology)

- KINGSING

- Primera

- Universal Labeling Systems

Each of these companies offers distinct advantages and technologies that address various industry needs.

1. Autmachine

Autmachine was founded in 2016 in Guangdong Province, China. The company develops fully automated and semi‑automated labeling machines. Their mission is to revolutionize the labeling industry by offering high‑performance, efficient, and accurate equipment. Autmachine targets industries such as food & beverage, cosmetics, pharmaceuticals, household chemicals, and FMCG.

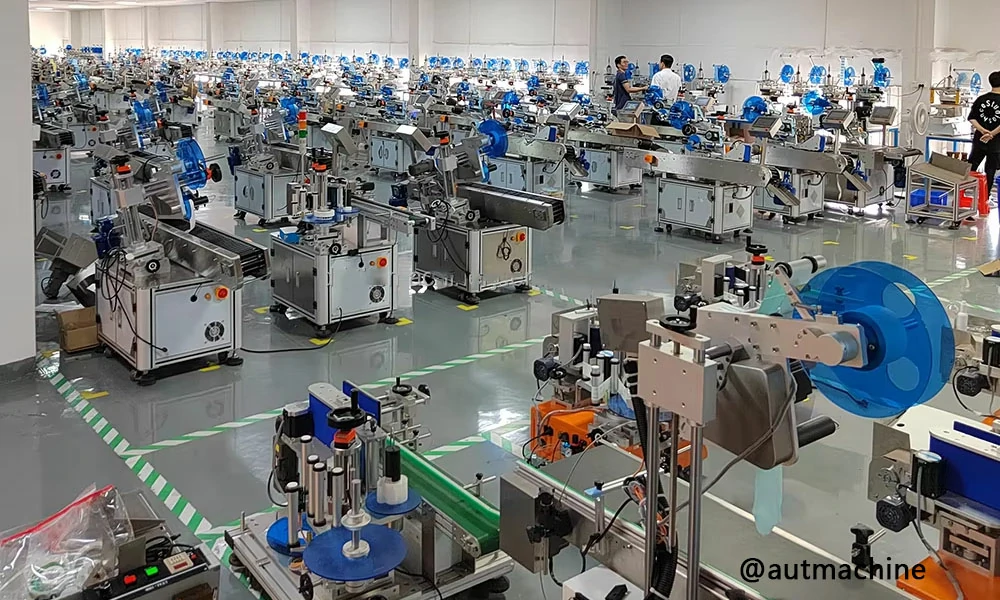

Autmachine operates assembly workshops, debugging areas, R&D offices, and delivery docks. They emphasize quick turnaround on custom equipment and flexibility in production.

Autmachine offers several types of machines:

- Fully automatic labeling machines for high‑speed lines (60–300 pcs/min), featuring high accuracy (±0.1 mm).

- Semi‑automatic bottle labelers for smaller setups (15–30 pcs/min) with accuracy of ±0.5 mm.

- Bottle labeling machines able to apply labels to round, square, and irregular bottle shapes.

- Flat labeling machines for boxes, jars, cartons, or flat products that integrate easily into existing lines.

- Hot‑melt glue labeling applicators with speeds up to 250 bottles/min and customizable workstations.

- Corner and single‑side labeling equipment designed for specialized use cases .

- Card‑labeling (paging function) machines for flat cards and inserts.

Each product is modular and tailored to production line requirements. Autmachine supports fast delivery, custom integration features, and testing samples before purchase .

Autmachine competes through:

- Fast delivery—promising customized machines in as little as three days .

- High performance—machines match global accuracy and speed standards .

- Customization—clients can design workstations for round, flat, or corner labeling .

- Local support—they service customers directly from China, reducing lead times and service costs compared to Western alternatives.

- Cost‑effectiveness—they appeal to buyers who want automation without the premium pricing of Western brands.

Autmachine offers comprehensive customer support, including training, maintenance, and spare parts supply. Their team works closely with clients to ensure that machines meet production goals and regulatory standards.

2. Accraply (BW Labeling)

Accraply is the new name for BW Labeling, following a series of mergers under the ProMach umbrella. The company focuses on high-speed, pressure-sensitive labeling systems for a wide range of package types, including round containers, pouches, and cartons.

Technical Highlights.

- Speeds up to 400 products per minute in wipe-on or tamp applications.

- Integrated servo drives for consistent label placement within ±0.05 mm.

- Options for roll-to-roll, shrink-sleeve, and RFID-capable labels.

Typical Use Cases.

- Beverage lines labeling bottles and cans.

- Pharmaceuticals requiring tamper-evident labels.

- Personal care products with multicontour packaging.

Standout Features.

- Modular design lets plants add new label heads or sensors without major rewiring.

- Live remote diagnostics available through ProMach’s cloud service.

- Wide spare-parts network in North America, Europe, and Asia for fast support.

3. EPI (ID Technology)

EPI, part of ProMach’s ID Technology group, has long been recognized for its custom labeling systems. The firm combines modular units to handle everything from side-apply to wrap-around labeling, with solutions for extreme environments.

Technical Highlights.

- Labeling speeds up to 200 products per minute for standard pressure-sensitive applications.

- Tool-free changeovers for label size adjustments in under two minutes.

- Optional vision-guided alignment to keep labels square on each item.

Typical Use Cases.

- Harsh-environment labeling for chemical drums or outdoor equipment.

- Food and beverage packaging where sanitary design and wash-down are critical.

- Logistics operations applying pallet or case labels.

Standout Features.

- InMotion™ Visualizer software for line-speed simulations before installation.

- Broad accessories catalog, from applicator heads to spare rollers.

- Dedicated personal support teams in key markets.

4. KINGSING

Based in Shanghai, KINGSING has grown since 2000 into a full-service supplier of print-and-apply labelers, dispensers, and rewinders. The company focuses on cost-effective machines that still meet ISO and CE quality standards.

Technical Highlights.

- Simple HMI touchscreen with pre-loaded recipes for common labels.

- Heavy-duty dispensers rated for 1 million cycles without replacement.

- Optional thermal-transfer print engines from leading brands (e.g., Zebra, Sato).

Typical Use Cases.

- Low- to mid-volume production lines in food packaging.

- Warehouse shipping labels on cartons and pallets.

- Retail back-of-store price labeling.

Standout Features.

- Very competitive pricing for entry-level automatic applicators.

- Comprehensive test reports for each machine before shipment.

- Local agent network in Asia and the Middle East.

5. Primera

Primera has built its name on compact, bench-top label applicators and color label printers. The firm caters to small businesses and labs that need up to 1,500 labels per hour without a full production line.

Technical Highlights.

- AP360 and AP380 models run up to 1,200 and 1,500 labels per hour, respectively.

- Auto-tension control prevents label skew.

- Support for die-cut, continuous, and RFID labels.

Typical Use Cases.

- Pilot runs in product development labs.

- Custom small-batch labeling for craft breweries or cosmetics.

- On-demand printing and application at point of packaging.

Standout Features.

- Small footprint (under 0.5 m²) fits on most workbenches.

- User-friendly software with Windows and macOS drivers.

- USA-based support with overnight spare-parts shipping.

6. Universal Labeling Systems

Since 1984, Universal Labeling Systems has produced a wide range of automatic label applicators, including wipe-on, tamp, and tamp-blow models. With speeds up to 250 parts per minute, the company serves many industries from food to electronics.

Technical Highlights.

- ±0.01-inch placement accuracy using servo control.

- Variety of head styles for front-and-back or wrap-around tasks.

- Tool-free label roll changes in under one minute.

Typical Use Cases.

- High-speed electronics component labeling.

- Medical device packaging requiring cleanroom compatibility.

- Automotive part identification tags.

Standout Features.

- 30-day performance guarantee on all standard machines.

- Fully open-source electronics and software to avoid vendor lock-in.

- Extensive library of case studies for different applications.

Why Choosing the Right Label Applicator Company Matters

Selecting a label applicator provider is more than just buying a machine. It impacts production efficiency, product quality, and ultimately, customer satisfaction. A good label applicator reduces waste, prevents recalls caused by incorrect labeling, and keeps production lines running smoothly.

Choosing a top label applicator company means investing in machinery that:

- Maintains consistent labeling accuracy

- Reduces downtime through reliable components

- Supports fast changeovers for different products

- Offers strong technical support and training

- Incorporates the latest automation for productivity gains

When a company like Autmachine offers not only advanced machines but also strong customer support and flexible solutions, it makes a significant difference for manufacturers. It is also crucial to consider how a company’s machines integrate with existing systems and future upgrades.

Industry Trends Shaping Label Applicators in 2025

The label applicator market is evolving rapidly due to several global trends:

- Automation and Smart Technology: More machines include sensors, cameras, and software that automate quality checks and reduce human error.

- Flexible and Modular Systems: Manufacturers demand equipment that can adapt quickly to new label formats, materials, and production volumes.

- Connectivity and Data Analytics: IoT-enabled devices provide real-time insights to improve maintenance scheduling and production planning.

- Sustainability: Eco-friendly materials and energy-efficient machines are becoming standard expectations.

- Regulatory Compliance: Stricter labeling laws require high accuracy and traceability, pushing companies to invest in advanced applicators.

Companies like Autmachine are responding to these trends by delivering scalable, smart, and customer-friendly labeling solutions.

Conclusion

In 2025, the label applicator market is dynamic and growing, fueled by the increasing need for automation, accuracy, and flexibility in labeling. Companies like Autmachine have distinguished themselves by offering adaptable, reliable, and easy-to-use label applicators that meet the demands of various industries.

Choosing the right label applicator company can significantly impact production efficiency and product presentation. As the market evolves, businesses will benefit from partnering with companies that combine strong engineering, customer focus, and forward-looking technology.

FAQ

A label applicator is a machine designed to apply labels to products, containers, or packaging. It helps improve labeling speed, accuracy, and consistency—essential for branding, logistics, and regulatory compliance.

Yes, Autmachine and other leading manufacturers provide full customer service, including installation, training, maintenance, and spare parts, ensuring smooth operation and minimal downtime.

Automatic label applicators operate with minimal human intervention and are suited for high-speed production lines. Semi-automatic models require manual loading or activation and are ideal for smaller batches or lower-volume production.

Autmachine is known for its customer-focused design, modern features like touchscreen controls and sensor-based detection, and its ability to customize machines to meet various production requirements.

Most modern label applicators are designed for easy integration with existing systems, including conveyors, coding printers, and robotic arms. This compatibility helps manufacturers streamline operations.