what is a plc?

A Programmable Logic Controller (PLC, Programmable Logic Controller) is a digital computer designed for industrial automation.PLCs are mainly used to monitor, control, and protect equipment and machines in the manufacturing process, especially in various industrial applications where they play a vital role.

It is programmed to perform a variety of complex tasks, replacing traditional relay and switching control systems.PLC’s great flexibility and reliability make it an indispensable core component in modern production automation systems.

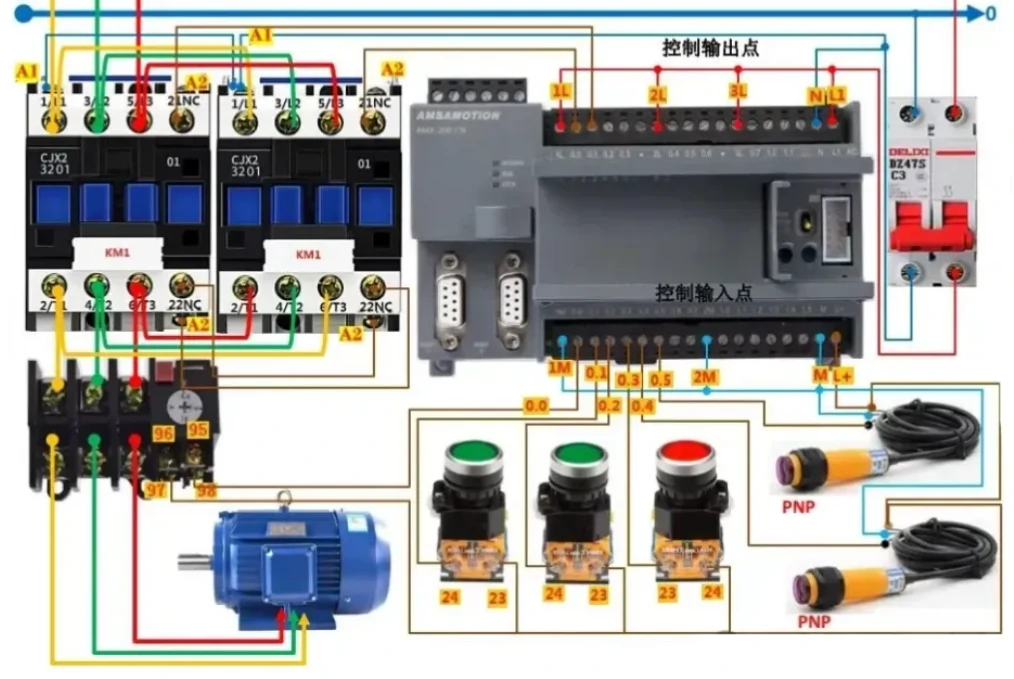

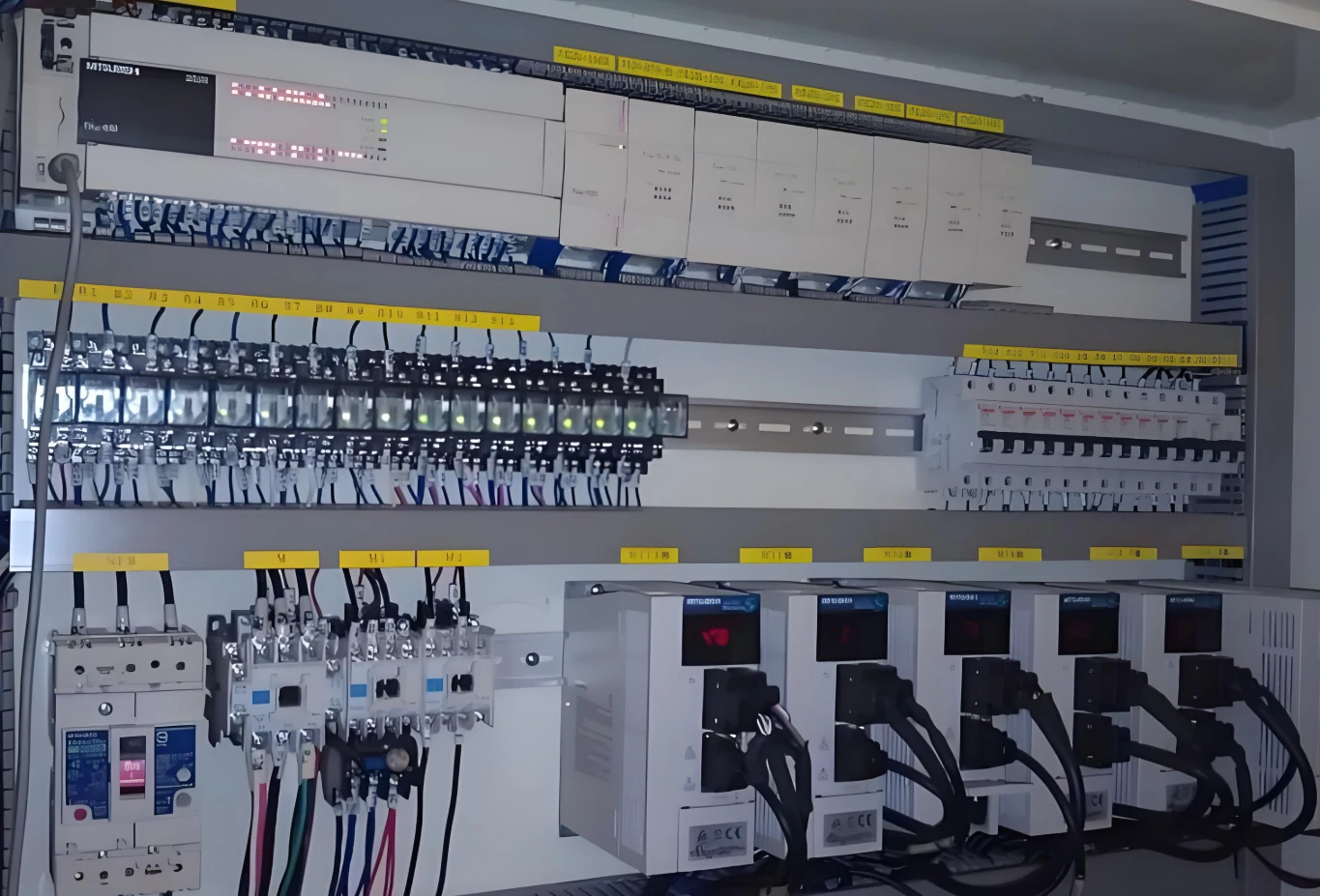

PLC is usually composed of hardware and software, where the hardware part includes the central processing unit (CPU), input/output modules (I/O), power supply modules, etc., and the software part is the user-written program, which determines how the PLC processes the input signals and generates the output control instructions.

The main function of PLC is to receive input signals from field devices (e.g., sensors, switches, etc.), process them through internal programming logic, and then output control signals to drive execution devices (e.g., motors, valves, etc.) to perform corresponding operations. Specifically, the basic functions of PLC can be summarized as follows:

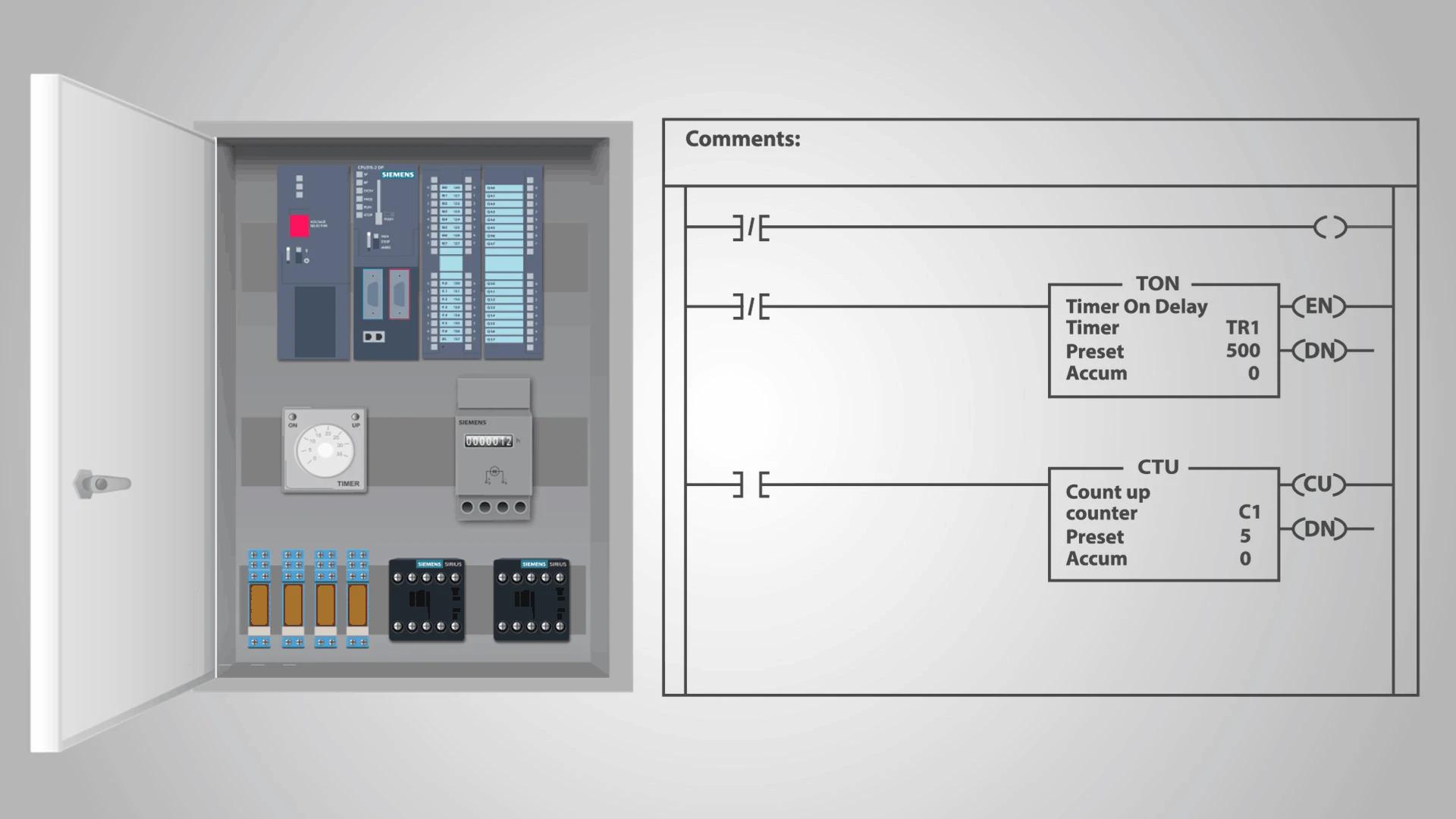

- Processing the control logic: After receiving the input signals, the PLC’s central processing unit (CPU) processes the signals according to predefined program logic. These logic programs are usually written using languages such as ladder diagrams, function block diagrams, etc. to determine the next action that should be performed.

- Output control signals: Based on the processing results, the PLC sends control signals through the output modules to the actuating devices, such as starting and stopping motors, adjusting valves, or starting other devices.

- Perform automation tasks: By continuously receiving input signals, processing data, and sending output signals, the PLC continuously performs tasks to ensure that automation operations in the production process are carried out efficiently and accurately according to the set parameters.

- Receive input signals: The PLC receives signals from on-site sensors or switches through input modules, which can be digital (on/off) or analog (temperature, pressure, etc.).

Through these basic functions, PLC can realize precise control of industrial equipment, which not only improves production efficiency but also ensures the stability and safety of the system. As a result, PLCs are widely used in all types of industrial automation scenarios, especially in complex manufacturing, process control, and energy management.

Historical Background of PLC

Early Development of PLC

Programmable Logic Controllers (PLCs) were originally developed in the late 1960s with the primary purpose of replacing traditional relay control systems. Traditional relay control systems utilize mechanical relays and contactors to perform control tasks, and while they have played an important role in industrial automation in the past, they have many limitations. First, relay systems are very complex to modify and commission, even requiring physical wiring modifications; second, the sheer number of relays and contactors, the complexity of the electrical equipment, and the space requirements make the system not easy to expand and maintain.

To improve the flexibility and reliability of the control system and to reduce time and labor costs, PLC came into being.PLC provides the function of programmed control, the user can change the control logic through the software without needing rewiring, which greatly improves the flexibility and efficiency of the production process. Compared with relay control systems, PLCs offer higher reliability and fewer failures can operate stably in industrial environments, and cope with a wide range of electromagnetic interference and harsh conditions.

PLC Technology Evolution

With the rapid development of computer technology and the continuous progress of control theory, PLC has undergone a continuous technological evolution. From the initial simple control logic to today’s multi-functional control platform capable of handling complex tasks, PLC has gradually become a core component of modern industrial automation systems.

While early PLCs could only handle simple switching controls and sequential operations, today’s PLCs have widely integrated digital signal processing, analog signal acquisition, data storage, complex algorithms, communication protocols, and other functions to handle more complex industrial control needs. With the introduction of new technologies such as the Industrial Internet (IIoT), cloud computing, and big data, PLCs continue to evolve towards intelligence and remote control.

Modern PLCs are not only equipped with powerful data processing capabilities but are also able to seamlessly integrate with other devices, systems, and platforms to achieve more precise and efficient automation control.

Overall, PLC has become the core of modern manufacturing and automation control from the initial relay replacement tool, through technological innovation and continuous development, promoting intelligent and efficient production in many industries.

Main Components of PLC

Central Processing Unit (CPU): It is the core part of PLC, responsible for the operation and management of the whole control system, it executes the PLC program, processes the input signals, and generates the corresponding output commands according to the program logic. It executes the PLC program, processes the input signals, and generates the corresponding output commands according to the program logic. The role of the CPU is similar to the “brain” of a computer, controlling the PLC’s various operational processes. Specifically, the CPU receives signals from the input module, after the logical operation of the program, to generate the corresponding control output signals, and command the actuator to perform the corresponding operation. With the continuous progress of technology, modern PLC CPU not only has stronger computing power but also supports real-time multi-tasking to meet more complex control needs.

Input/Output Module (I/O): It is the bridge between PLC and external devices, responsible for receiving signals from external devices and transmitting them to PLC, and vice versa, transmitting PLC commands to external devices. According to the type of signal, I/O modules can be divided into digital input/output (DI/DO) and analog input/output (AI/AO).

- Input Module: Used to receive signals from external devices (e.g. sensors, switches, buttons, etc.). The input module converts these signals into digital or analog signals that the PLC can process.

- Output module: receives the output signals processed by the CPU and converts them into control signals, which are transmitted to the actuators (e.g. motors, valves, indicator lights, etc.). The actuator performs specific actions according to these signals, such as switching circuits, starting equipment, or adjusting parameters.

- The I/O modules are designed so that the PLC can connect to a variety of sensors and actuators, process a variety of signals from the real world, and control the operation of machines and equipment.

Power: PLC systems require a stable power supply for proper operation. The power supply module provides the required power to the entire PLC system and ensures that the individual components operate within the specified voltage and current ranges. Modern PLCs typically use DC power supplies, but some systems support AC power inputs. Power supply modules not only provide basic power to the PLC but also need to have anti-interference capability and overload protection to ensure that the normal operation of the PLC is not affected during power fluctuations or transient failures. A high-quality power supply module is the key to ensuring the long-term stability of the PLC system.

Communication Interface: It is the channel to exchange data between PLC and other devices or networks. Through these interfaces, PLCs can exchange data with other PLCs, computers, sensors, actuators, and industrial equipment. Common communication protocols include Ethernet, Modbus, Profibus, CANopen, etc. These protocols enable PLCs to realize distributed control and remote monitoring in automation systems.

Working Principle of PLC

The PLC (Programmable Logic Controller), as the core component of industrial automation control, works based on a cyclic operation of input scanning, program scanning, and output scanning. Through this cyclic process, PLC can efficiently collect information, execute control logic, and output control commands to accomplish complex automation tasks.

Input Scanning: Input scanning is the first step in the PLC cycle. In this phase, the PLC receives signals from external devices through input modules. These signals usually come from sensors, buttons, switches, or other types of input devices. For example, the PLC may receive a reading from a temperature sensor, the switch status of a button, or a signal from a position sensor. The input module converts these analog or digital signals into a format that the PLC can understand and passes them to the central processing unit (CPU).

Program Scan: After completing the input scan, the PLC enters the program scan phase. In this phase, the PLC’s CPU processes the input signals according to a control program pre-written by the user. Control programs are usually logical control codes written through programming languages such as ladder diagrams, structured text, or function block diagrams.

Based on these control programs, the PLC’s CPU will make logical judgments and operations on the input signals to determine whether the system needs to perform certain specific actions. For example, if the signal from a temperature sensor exceeds a set threshold, the CPU may determine that the cooling system needs to be activated or a valve opened. The core task of program scanning is to analyze and process the input signals according to the set logic rules to determine the behavior of the control system.

Output Scanning: After completing program scanning, the PLC enters the output scanning stage. In this stage, the PLC sends control commands to external devices through the output module according to the results of program scanning. The output module converts the commands processed by the PLC into electrical signals that control the operating state of the device, such as starting a motor, opening a valve, or adjusting a sensor setting.

Output scanning ensures that the PLC’s control of external devices is based on program logic and feedback from real-time input signals. If required, the PLC can also dynamically adjust the output signals based on the instructions being executed, thus ensuring that the system operates as intended.

Cyclic Operation: PLCs operate on a cyclic process where input scans, program scans, and output scans are repeated at predetermined intervals. Typically, PLCs operate in very short cycles, enabling real-time control. During each scanning cycle, the PLC continuously acquires new input signals, executes the control program, and adjusts the output control instructions as needed to ensure stable operation of the entire system.

This cyclic operation enables the PLC to respond to changes in the state of the equipment on time and make appropriate decisions based on new data. For example, in an automated production line, the PLC continuously monitors the working status of the production equipment and adjusts the production process according to the sensor data to ensure product quality and production efficiency.

what is a plc programmer languages?

PLC (Programmable Logic Controller) programming languages provide flexible options for the development of industrial automation systems. Different programming languages are suitable for different control needs, from simple on/off control to complex process control. Various programming languages help engineers to write appropriate programs according to specific application scenarios. The following are some of the common programming languages used in PLCs:

- Ladder Diagram (LD): The most common PLC programming language, it is based on relay control circuit diagrams, similar to the ladder structure in the circuit diagrams, hence the name “ladder diagram”. Each ” ladder ” horizontal line” represents a control logic operation, usually consisting of relays, switches, pushbuttons, sensors, and other components. Vertical lines indicate the direction of current flow, which can help engineers clearly understand the logic of the control system. The most important feature of a ladder diagram is that it is highly similar to the traditional relay control circuit diagram, which is easy for electrical engineers to understand and operate. It realizes logic operations through the “on” and “off” of contactors, relays, and other logic elements. A ladder diagram is the most intuitive and easy-to-learn language in PLC programming, so it is widely used in industrial control, especially for switching control, sequence control, and simple alarm logic.

- Function Block Diagram (FBD): is a graphical programming language used to describe process control logic. FBD abstracts a control process into many function blocks, each representing a specific operation or process control unit. Engineers can modularize and simplify complex control processes by connecting these function blocks. The FBD language is commonly used to describe process control systems, where each function block acts as a processing unit and is connected by lines that represent signaling.FBD suits complex control tasks, especially in the process industry, automated production lines, and real-time control systems. Its graphical representation makes programming more intuitive, making it easier for engineers to debug and maintain the system.

- Structured Text (ST): It is a kind of text programming similar to high-level programming languages, and its syntax structure is close to that of high-level programming languages such as Pascal and C. It has powerful data processing and mathematical functions, and it can be used in a wide range of applications, especially in process industries, automated production lines, and real-time control systems. It has powerful data processing and mathematical operations and is suitable for writing complex control logic and computation-intensive operations.

- Instruction List (IL): is a simpler programming language for writing basic control instructions. It uses an assembly language-like format to control hardware through instructions and operators.IL implements control operations with intuitive instructions and is typically used in low-level control systems or simple control tasks.

- Sequential Function Chart (SFC): A programming language for describing the sequential logic of multiple steps.SFC graphically illustrates the steps of a process and their sequence by dividing the entire control process into a series of independent steps and controlling the transition of the steps through logical conditions.

The SFC language is well suited for complex sequential control tasks, especially in assembly line production, robotic arm control, and mass production, and can clearly express the logical relationships between the individual process steps. the advantage of SFC is that it can visually segment complex sequential processes, which makes it easy for engineers to design and debug their systems. Transitions and conditions between each step can be graphically represented clearly, making the control logic easier to understand and adjust.

PLC Application Areas

PLC (Programmable Logic Controller) has become a core component of automation control in several industries due to its high reliability, flexibility, and powerful control capability. It is capable of handling complex control tasks and realizing various industrial automation operations. The following are the major application areas of PLC:

- Manufacturing: In the manufacturing industry, PLCs are widely used in production line automation, machine control, packaging, conveying and assembling, etc. PLCs can efficiently control the production process, coordinate the work of the machines, reduce manual operations, and improve productivity and accuracy. Production line equipment such as conveyor belts, packaging machines, welding robots, etc., can be automated through the PLC to achieve control and ensure the production process’s smooth progress.PLC can also be real-time monitoring of the production state, troubleshooting, and starting the emergency response program, to protect the stability and reliability of the production line.

- Energy Management: PLCs are also widely used in energy management applications such as power, oil, and gas. In these industries, PLCs are used to monitor and control the operation of energy systems, such as power plants, oil rigs, and various equipment and processes in the natural gas transmission network. PLCs can collect data from various sensors in real-time and regulate the operation of the equipment according to a predefined control strategy to ensure efficient, safe, and sustainable use of energy.

- Transportation: PLCs are used in the transportation field mainly in railroads, traffic signals, and bridge control. In railroad systems, PLCs are used in train dispatching and signal control systems to ensure safe and accurate train operation. The train’s running speed, traveling path, signal status, and other information can be precisely controlled and adjusted through PLC’s real-time monitoring and data processing.

- Automatic Labeling Machine: PLC is significant in the application of automated labeling machines. Automated labeling machine is mainly used for bottled product labeling, it requires the system to be able to deal with a variety of bottle types, labeling specifications, and high-efficiency labeling needs.PLC in which the role is mainly reflected in the control of the labeling machine’s action process, such as bottle transfer, labeling accurate positioning, and attachment.

- Building Automation: PLCs are also being used more and more widely in building automation, especially in building automation control systems.PLCs are used to manage the operation of power, HVAC (heating, ventilation, and air-conditioning), lighting, and other systems in a building to ensure the comfort and safety of the environment inside the building. For example, PLCs can automatically adjust the air conditioning system operation based on indoor temperature, humidity, and air quality data to maintain a suitable indoor environment. At the same time, PLC can also control the lighting system to ensure that the lighting equipment in the building is automatically turned on or off according to the actual demand, to enhance energy utilization efficiency.

- Process Control: PLCs also play a vital role in process control in the chemical and pharmaceutical industries. Production processes in these industries are often continuous, complex, and require a high degree of accuracy, and PLCs can coordinate multiple control links, monitor the status of various types of equipment in the production process in real-time, and perform complex regulation and control tasks. For example, PLC can automatically adjust the working status of reactors, pumps, valves, and other equipment according to the feedback of temperature, pressure, flow and other sensors to maintain the stability and safety of the production process.

The application of PLC in automated labeling machines not only improves production efficiency but also reduces manual intervention and improves the automation level of the production line. With the improvement of intelligent demand, the role of PLC in automated labeling machines will be more important.

Advantages of PLC

- High Reliability: PLC is known for its high degree of reliability and ability to operate stablely under a wide range of extreme environmental conditions. It is designed with rugged hardware that is resistant to electromagnetic interference and vibration, making it suitable for a variety of harsh industrial environments. For example, in production plants, warehouses, chemical plants, etc., PLCs can still perform control tasks stably without system failure due to environmental changes. This makes PLCs a reliable industrial automation control system.PLC hardware is usually equipped with a redundant design, so that when a problem occurs in one part of the system, the system can be automatically switched to a backup system to ensure continuous operation, avoiding production stoppages or major failures.

- Flexibility and Programmability: The programmability of PLCs brings great flexibility. Unlike traditional relay control systems, PLC users can flexibly adjust the control logic by writing and modifying programs. In this way, PLCs can be adapted to different production requirements and working environments to meet diverse automation control tasks. For example, in the automated labeling machine system, according to the requirements of different bottle types and different label specifications, PLC can quickly adjust the control logic to change the position of the label, the angle of attachment, and other parameters, to adapt to new production requirements or equipment changes. This flexibility makes PLC play a great role in the changing production process.

- Adapt to harsh environments: PLC can work stably in harsh environments such as temperature, humidity, and electromagnetic interference. Many industrial production sites are often challenged by high temperatures, high humidity, or strong electromagnetic fields, and PLCs are designed with these factors in mind. Its enclosure is usually made of protective materials, which can effectively isolate the external environment from the interference of internal circuitry.

- Easy Maintenance and Diagnostics: A significant advantage of PLCs is their ease of maintenance and diagnostics. Modern PLCs are equipped with powerful self-diagnostic features that provide real-time error feedback in the event of a malfunction. Users or maintenance personnel can easily view fault codes, detect equipment operating status, identify problems, and take appropriate measures through the PLC’s display interface.

In addition, the PLC’s program and control logic can be accessed and modified remotely, and system updates and upgrades are easy. Users can monitor and control from a computer or mobile device, eliminating the need for cumbersome on-site adjustments and greatly simplifying the maintenance and operation process.

Future Trends in PLCs

- IoT Integration: In the future, PLCs will be more integrated with IoT devices to realize smarter industrial automation. By networking with sensors, devices, and systems, PLCs will be able to access data in real time, enhancing the intelligence, automation, and remote control of production processes.

- Cloud Computing and Big Data: With the development of cloud computing and big data technologies, PLCs will be integrated with cloud platforms to provide more efficient data analysis and decision support. Production data can be uploaded to the cloud for real-time monitoring and optimization, helping to improve productivity, equipment maintenance, and fault prediction.

- Artificial Intelligence Application: PLC systems will gradually introduce artificial intelligence and machine learning technologies, enabling the control system to be self-adaptive and automatically adjusted.AI will help PLCs analyze the working environment and production process more intelligently, to optimize the control strategy and improve the system’s autonomy and responsiveness.