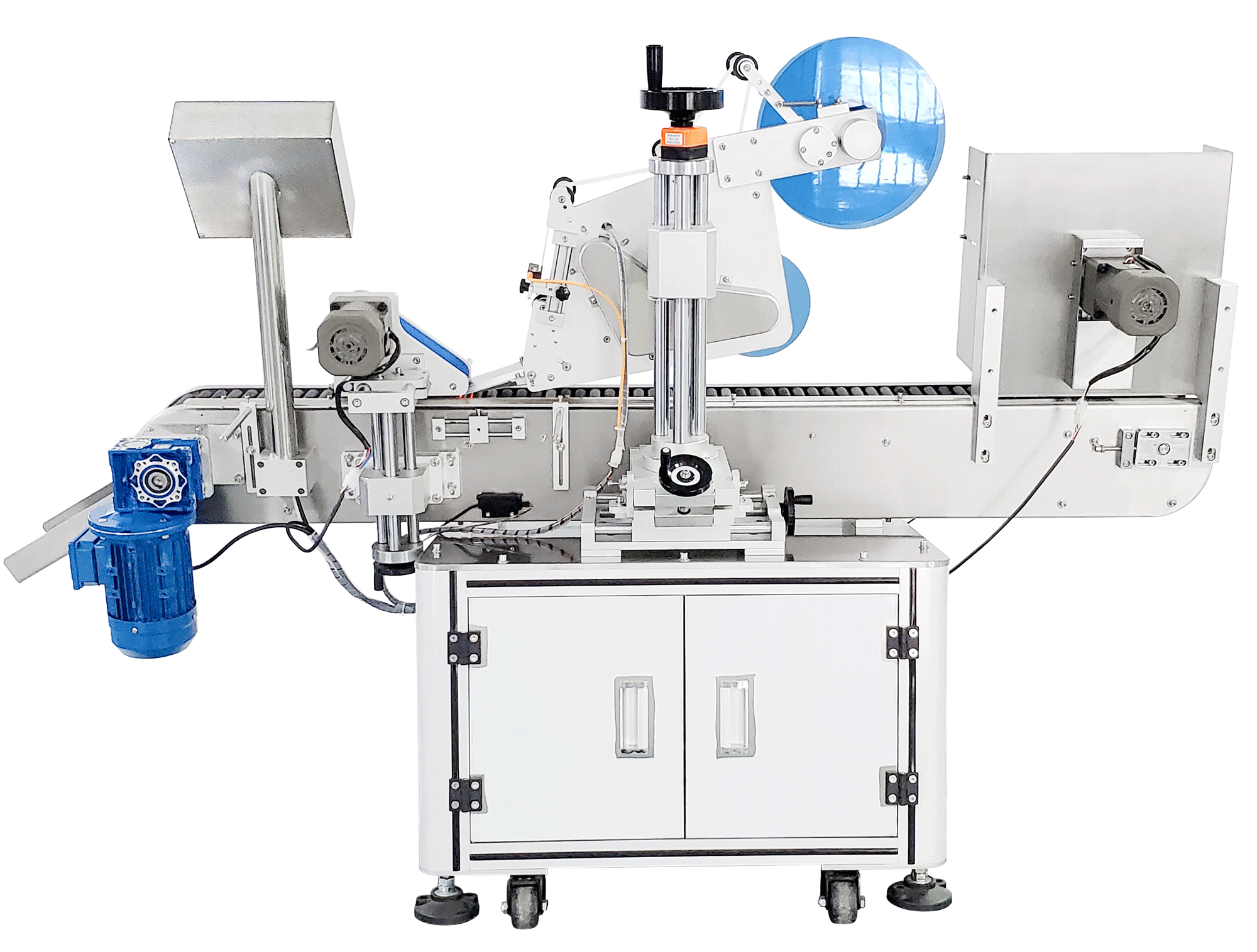

Fully Automatic Horizontal Bottle Labeling Machine

Suitable for labeling cylindrical objects – full circumference and half circumference labeling. It uses horizontal conveying and horizontal labeling methods, enhancing stability and improving labeling efficiency.

- Automates the entire labeling process

- Suitable for round bottles, ampules and vials items

- Simple to set up and monitor, reducing labor costs

Home » Bottle Labeling Machine » Horizontal Bottle Labeling Machine

Our fully automatic horizontal labeling machine can be equipped with a coding machine or inkjet printer on the labeling head to print production dates, batch numbers, barcodes, and other information on the labels. Alternatively, the inkjet printer can be installed on the conveyor belt to print production information (such as date, batch number, and barcode) on the products before or after labeling.

Core Working Principle: The product is separated by the bottle separator wheel and placed on the conveyor belt. Sensors detect the product and send a signal to the labeling control system. The system then triggers the motor to dispense the label at the correct position and applies it to the designated labeling area. The product moves through the labeling device, where the label is wrapped around the product as it rotates. This completes the labeling process.

Operating Process: Place products (in the feeding box) → Separate products and position them on the conveyor rollers → Product conveyance → Product detection → Labeling → Label wrapping → Collect labeled products.

Fully Automatic Horizontal Bottle Labeling Machine Technical Parameters

Here are the key technical parameters of our fully automatic horizontal bottle labeling machine, showcasing its efficiency, accuracy, and flexibility.

|

Model

|

Parameters

|

|---|---|

|

Labeling Accuracy |

+/- 1 mm |

|

Labeling Speed |

300 pcs/min |

|

Product Diameter (for round bottles) |

φ10mm – φ30mm |

|

Machine Construction |

Stainless steel frame for durability and easy cleaning |

|

Air Pressure |

4-6 bar (for labeling head and sensor operation) |

|

Conveyor Speed |

Adjustable speed from 1-20m/min |

|

Label Size |

Length: 20mm – 300mm, Width: 20mm – 120mm (customizable) |

|

Control System |

PLC (Programmable Logic Controller) with touch screen for easy operation and parameter setting. |

|

Applicable Label Material |

Paper, film, or adhesive labels (customizable) |

|

Equipment Size |

2040mm×690mm×1370mm |

|

Power Supply |

220V/50HZ |

|

Weight |

220 Kg |

|

Price |

$$$ |

|

Coding System |

Optional inkjet printer or coding machine for printing production dates, batch numbers, and barcodes. |

|

Labeling Method |

Horizontal conveyor and labeling mechanism |

|

Product Detection |

Photoelectric sensors for accurate detection and positioning of products |

|

Suitable for |

Cylindrical bottles, cans, and similar round containers. |

|

Custom Support |

|

Structure Detailed of Horizontal Labeling Machine

The horizontal labeling machine is composed of several key structural components, each designed to ensure precise and efficient labeling of cylindrical products. Below is a detailed breakdown of the machine’s structure

Label Roller

Pressing Device

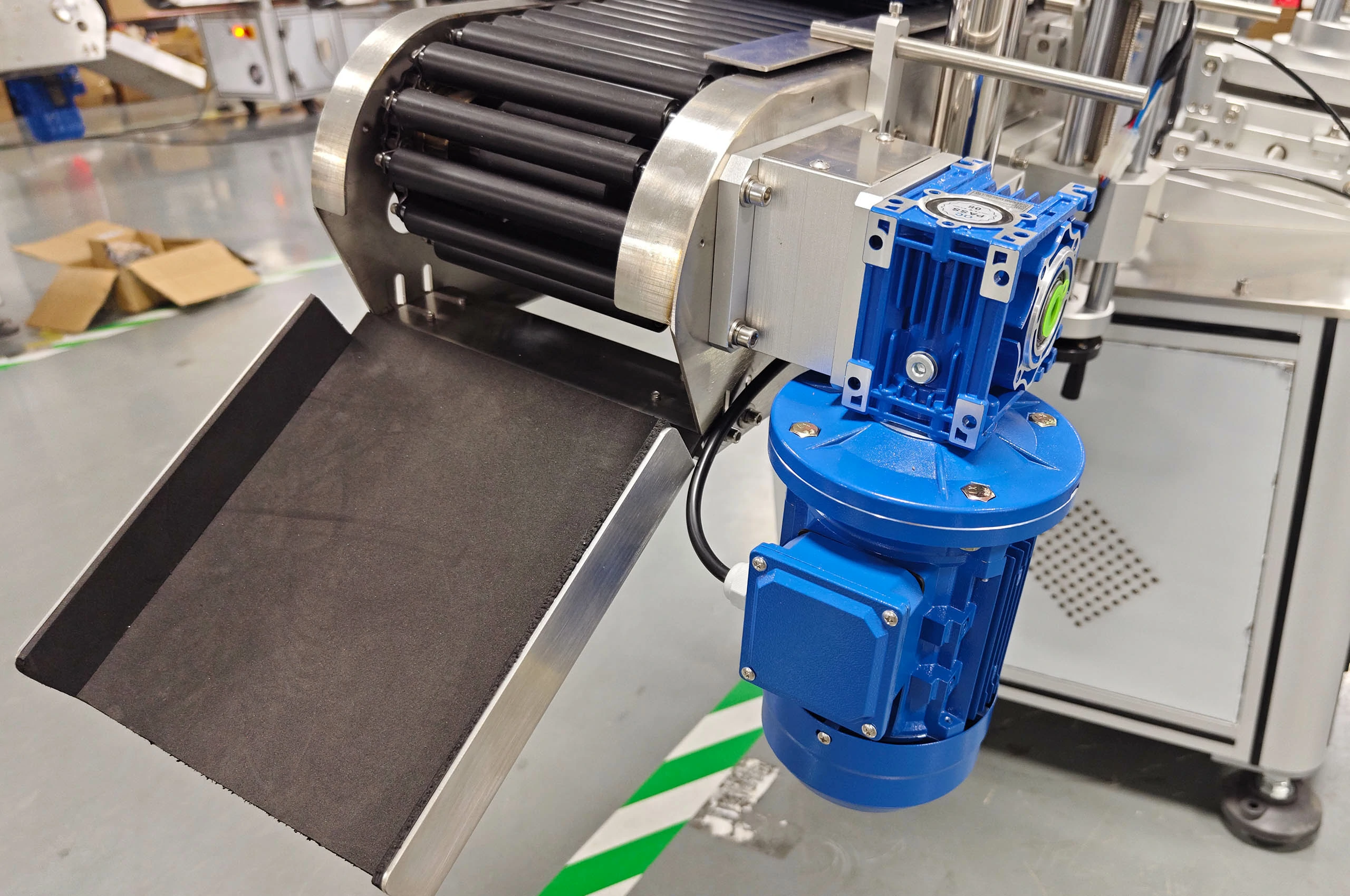

High Speed Motor

Electric Cabinet

Touch Screen

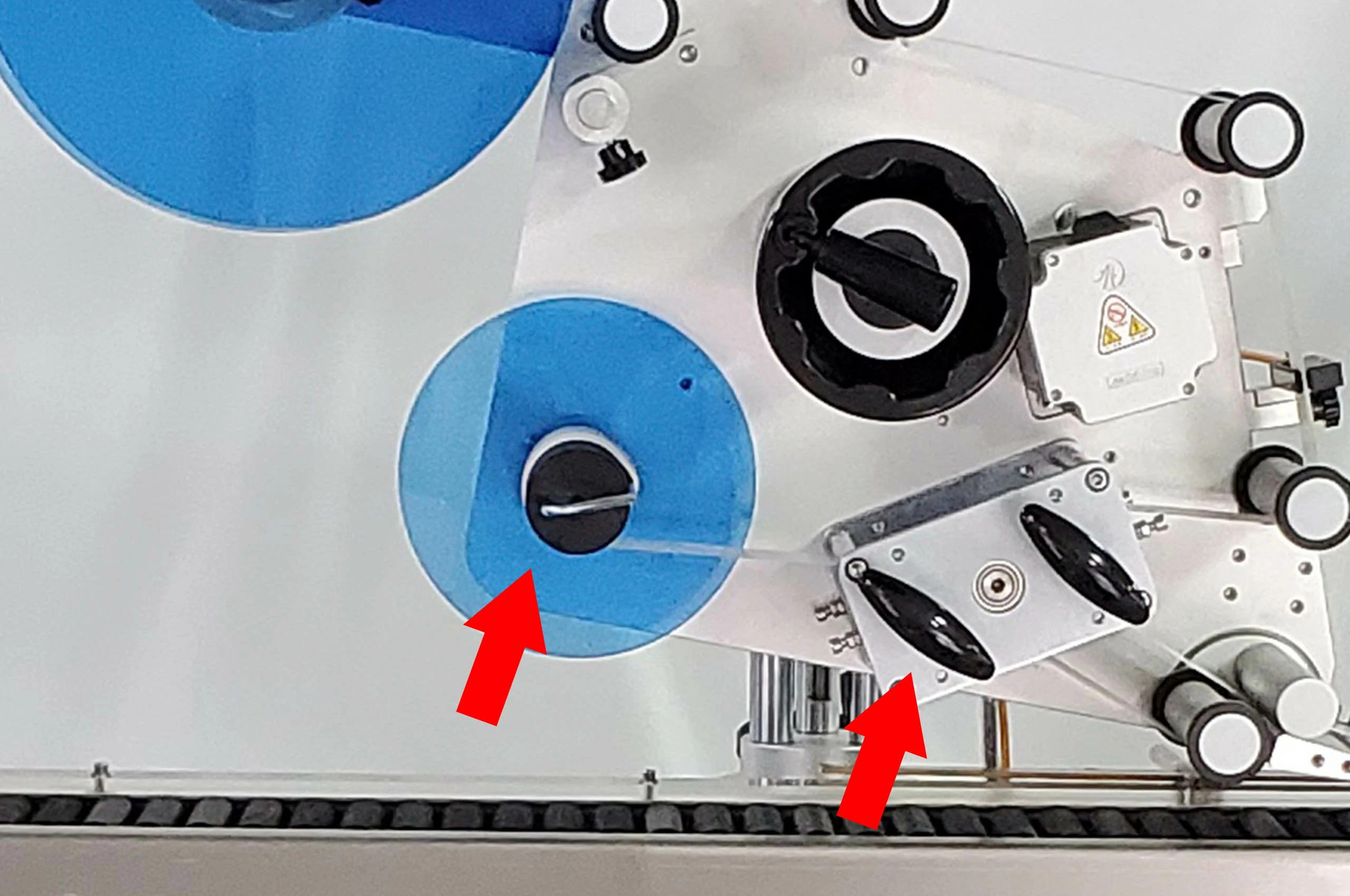

Bottle Separation Mechanism

Label Tray

Adjusting Wheel

Label Sensor

Detect the presence and positioning of labels. Ensure labels are assigned at the correct time and position on the product.

Product Sensor

Detects the presence, location, and sometimes direction of the product as it moves along the production line.

Recycling & Towing

Collect stripped paper or scrap to prevent accumulation and clogging and keep the production line clean.

Label Peeling Mechanism

The label is separated from the label paper and transported and positioned to the bottle to be labeled.

Label Pressure System

It ensures the label is applied precisely and evenly on the container, preventing wrinkles, bubbles, or misalignment.

Adjusting Base

A component that can adjust the positioning or alignment of key parts of the machine, such as the labeling head.

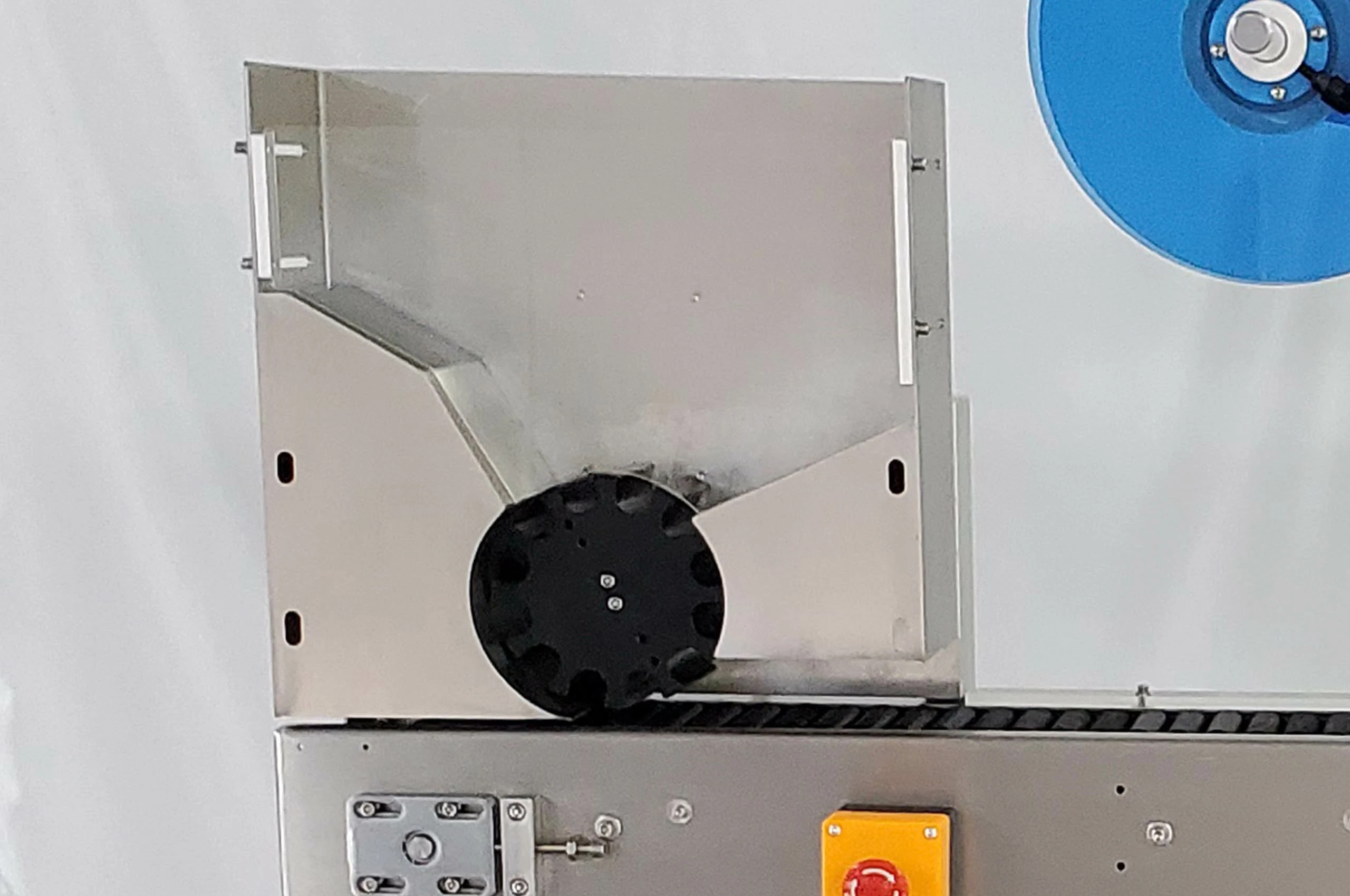

Bottle Separation Mechanism

It separates and spaces the bottles (or other containers) as they move along the conveyor belt.

Blanking Mechanism

It transfers the labeled products from the machine to the receiving area or moves them to the next process and packaging area.

Speed Controller

It adjusts the speed of the conveyor, label transfer system, and bottle separation mechanism according to production needs.

Electric Cabinet

The electric cabinet ensures the machine operates smoothly and safely, with real-time monitoring and control.

It Can Be Used for Hundreds of Different Containers

Whether you’re dealing with bottles, jars, cans, cosmetic containers, food packaging, or other cylindrical objects, this Horizontal Labeling Machine can be used for hundreds of different containers.

Horizontal Labeling Machine for Various Industries

The horizontal labeling machine is designed to meet the needs of a wide range of industries, providing efficient, precise, and flexible labeling solutions. Whether it’s for the food and beverage industry, pharmaceuticals, cosmetics, chemicals, or other sectors, this machine can label various containers

Watch Our Automatic Horizontal Bottle Labeling Machine in Action!

Experience the precision and efficiency of our Automatic Horizontal Bottle Labeling Machine. Watch as it seamlessly labels cylindrical containers with accuracy and speed. See how easy it is to adjust for different container sizes and how the machine handles various labeling tasks, ensuring perfect application every time.

Why Choose AUTmachine?

Choose AUTmachine for reliable, efficient, and flexible labeling solutions that keep your production line running smoothly.

Customizable Solutions

Our machines offer flexible options for label speeds, coding, and inspection systems, providing a tailored solution that meets the specific needs of your production line.

Precision and Efficiency

Machine guarantees high accuracy and consistent label application, even for varied container shapes and sizes, minimizing errors like misalignment, wrinkles, and bubbles.

User-Friendly Design

The intuitive interface and adjustable settings make operation easy, allowing quick switching between different container sizes to ensure minimal downtime during production changes.

After-Sales Support

AUTmachine provides dedicated customer support, with expert training and ongoing assistance to ensure your machine operates at optimal efficiency and reliability over time.

Horizontal Labeling Machine FAQs

A horizontal labeling machine applies labels to cylindrical containers like bottles, jars, cans, and tubes as they move along a horizontal conveyor system.

Yes, the machine can be configured to apply multiple labels to a single container, including front and back labels or wraparound labels.

Yes, the machine can be customized to meet specific needs, such as label size, speed, and additional features like coding or inspection systems.

Yes, the horizontal labeling machine can be easily integrated with other systems like filling machines, capping machines, and packaging lines.

AUTmachine offers a warranty period for all components, along with full technical support, training, and after-sales service to ensure smooth operation.

Contact us

If standard labeling machines don’t meet your needs, we can manufacture a custom labeling machine based on your production requirements!

Please take a moment to fill out the form on the right with some details about your product labeling needs, so our engineers can understand how to best assist you and provide tailored advice.

Get Your Automatic Labeling Machine Quote Here!

Please fill out this form to submit a request for quote(* denotes required fields)