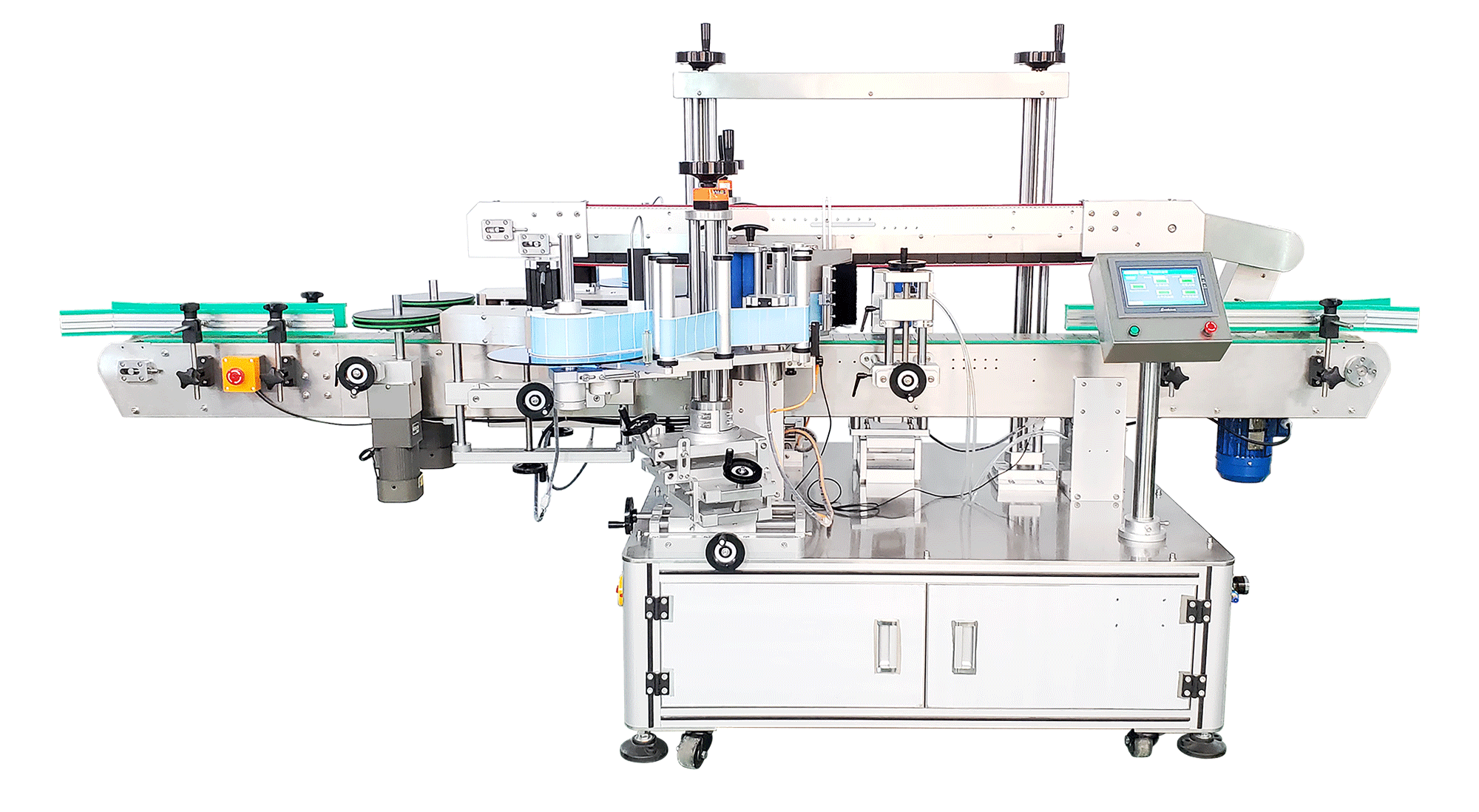

Round & Flat Bottles Integrated Labeling Machine

This machine is designed to label both round and flat bottles on a single device, saving resources and improving productivity. It eliminates the need for separate machines, offering a cost-effective, efficient solution for diverse labeling needs.

- Saving space and resources

- High labeling accuracy with minimal errors

- Offers video support for easy installation and troubleshooting

Home » Bottle Labeling Machine » Round & Flat Bottles Integrated Labeling Machine

This integrated labeling machine is capable of labeling three different product types (flat, square, and round bottles) for full-wrap, single-side, and double-side labeling. It supports precise positioning labeling and can be adjusted according to the shape of the bottle. It features automatic bottle spacing, dual guiding chains for alignment, double labeling for precision, and a smart control system characteristics. Durable and GMP-compliant, it ensures efficient operation.

Working Principle: The sensor detects the product as it passes through and sends a signal to the labeling control system. The system then sends the label to the correct position, ensuring it is applied precisely on the designated area of the bottle. As the product moves through the labeling unit, the label is smoothly applied, completing the labeling process.

Operation process: Put the product (can be connected to the pipeline) -> product transport -> product separation -> Labeling (equipment automatic realization) -> Collection of labeled products.

Technical Parameters

Here are the key technical parameters of our round & flat bottles integrated labeling machine. Designed for versatility and efficiency, it meets the labeling needs of industries like food, beverage, pharmaceuticals, and cosmetics.

|

Model

|

Parameters

|

|---|---|

|

Labeling Accuracy |

+/- 1 mm |

|

Labeling Speed |

160 pcs/min |

|

Product Size |

Length: 20mm ~ 250mm Width: 30mm ~ 90mm Height: 60mm ~ 280mm |

|

Labels Applied |

1 or 2 (front & back) |

|

Label Size |

Length: 20mm ~ 300mm width (bottom paper width) : 20mm ~ 170mm |

|

Control System |

PLC with touch screen interface |

|

Labeling Type |

Self-adhesive, pressure-sensitive labels |

|

Equipment Size |

3020mm×1560mm×1570mm |

|

Power Supply |

220V/50HZ |

|

Weight |

473 Kg |

|

Price |

$$$ |

|

Application |

Suitable for round, flat, and irregular-shaped bottles |

|

Custom Support |

|

Structure Detailed of Round & Flat Bottles Labeling Machine

The structure of the round & flat bottles integrated labeling machine is designed for versatility, ease of use, and durability. Here’s a detailed breakdown of its key components.

Label Stripping Plate

Pressing Device

Spacing Wheel

Emergency Button

Electric Cabinet

Touch Screen

High Speed Motor

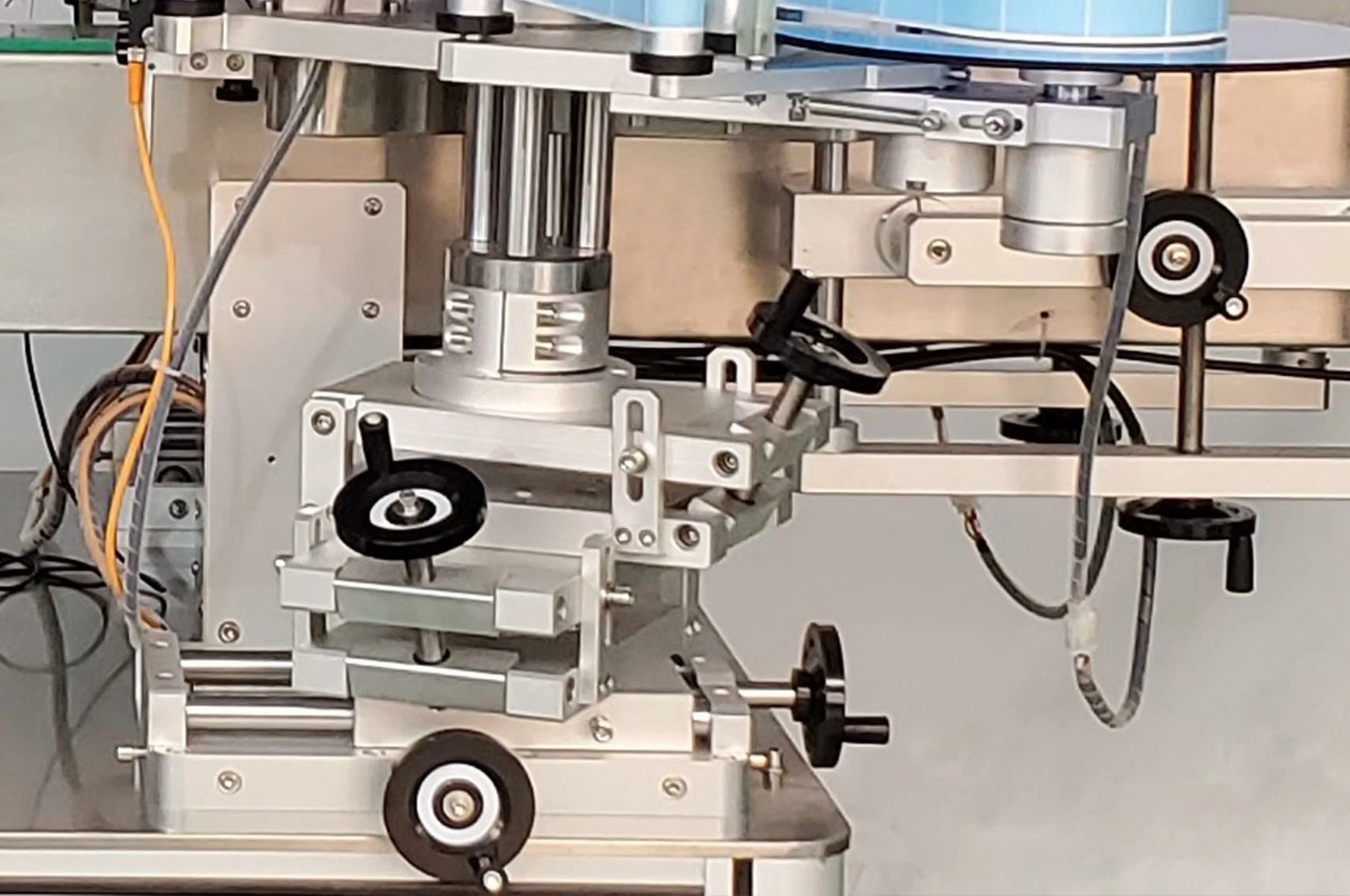

Adjusting Wheel

Label Sensor

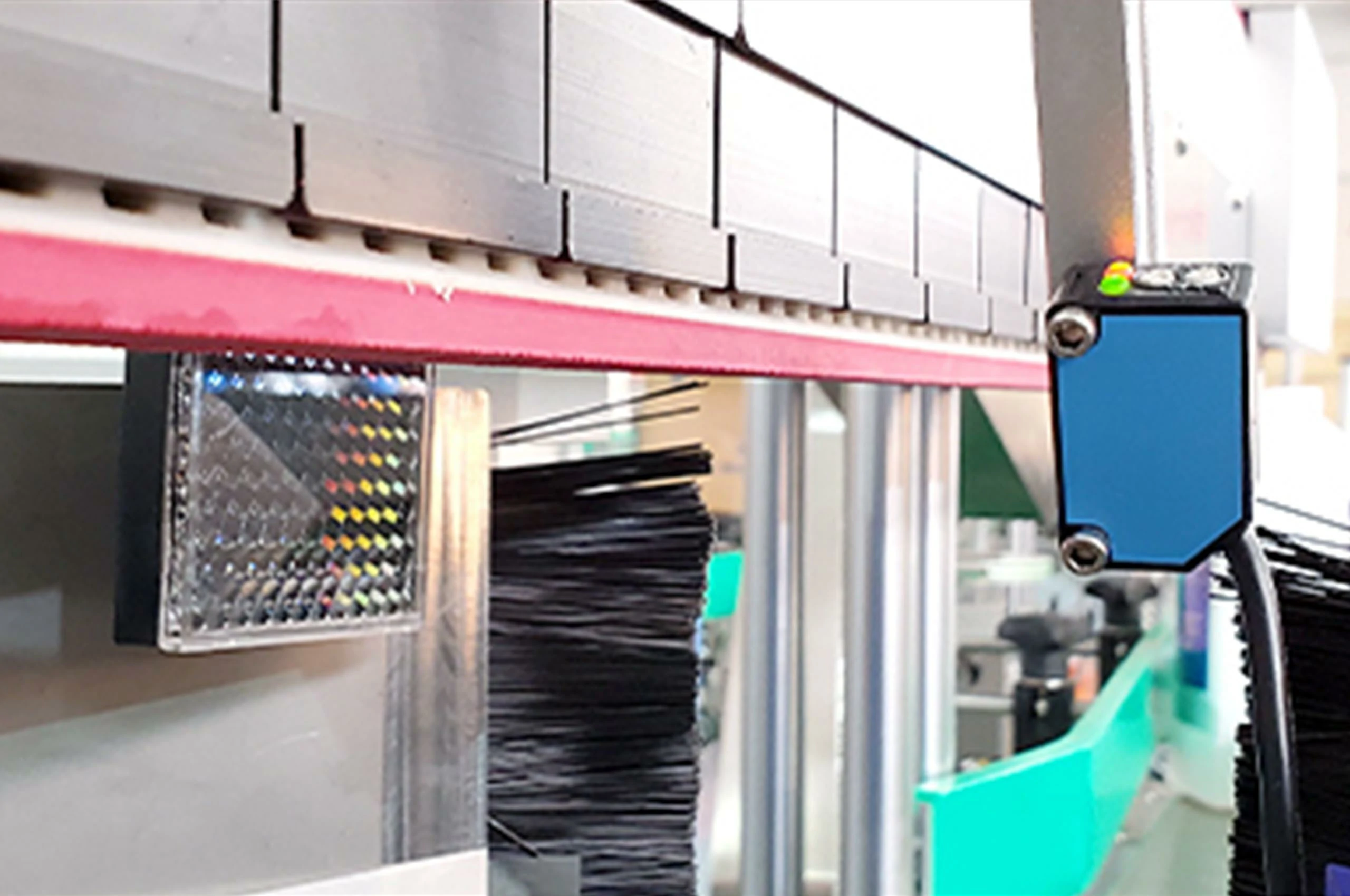

Detect the presence and positioning of labels. Ensure labels are assigned at the correct time and position on the product.

Product Senson

Detects the presence, location, and sometimes direction of the product as it moves along the production line.

Spacing Wheel

It ensures that the bottles are spaced evenly as they move through the labeling station, allowing for precise and accurate label application.

Positioning Device

Make sure bottles or containers are correctly aligned with the correct labels.

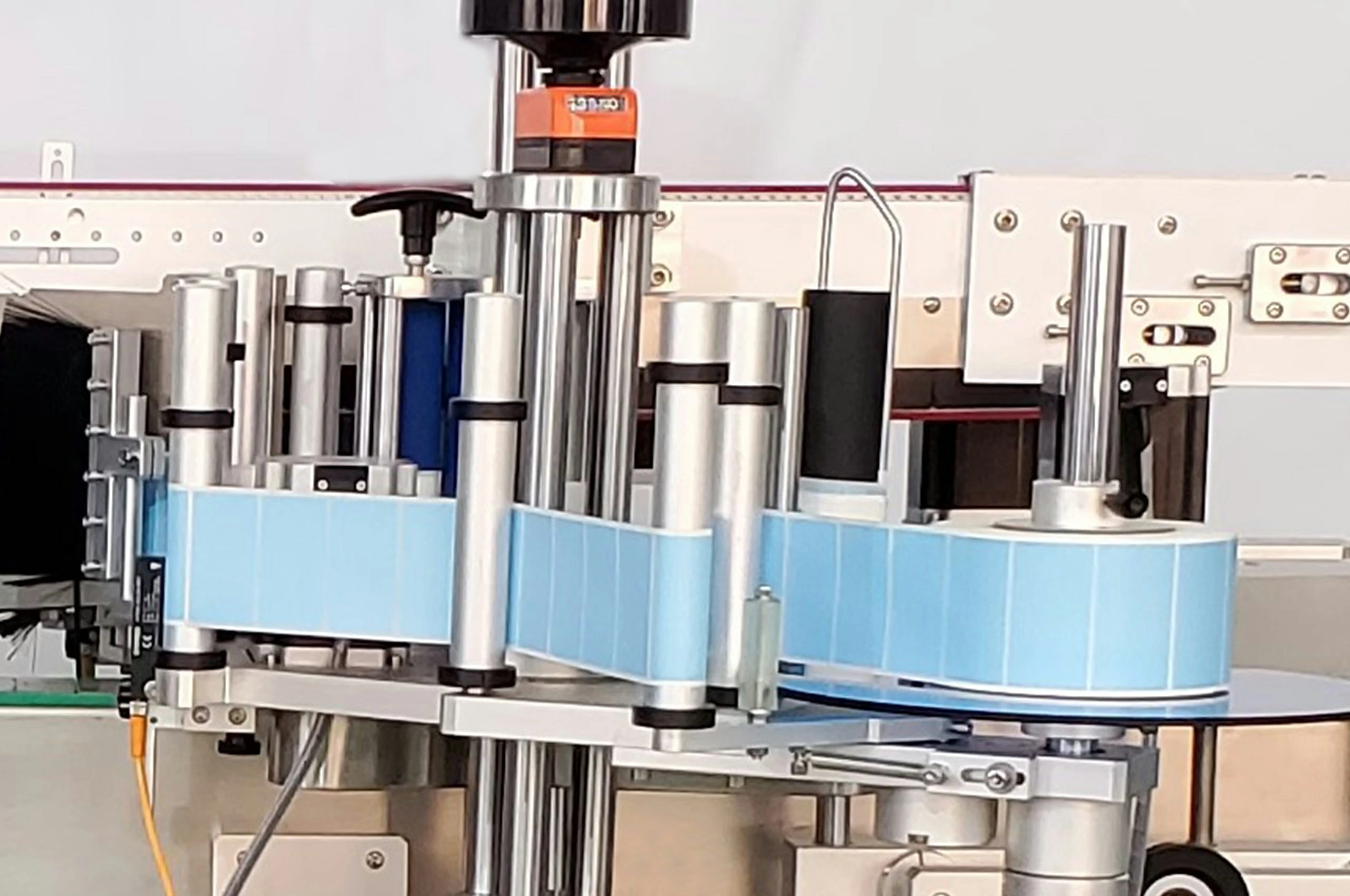

Label Stripping Plate

Used to separate the label from the backing paper or liner and ensure smooth application onto the bottle.

Recycling & Towing

Collect stripped paper or scrap to prevent accumulation and clogging and keep the production line clean.

Adjusting the Base

Process of modifying the foundational setup of the machine to accommodate different bottle sizes, shapes, or label dimensions.

Labeling Head

The labeling head ensures precise and consistent label placement for various types and shapes of products.

Touch Screen

Providing an intuitive and user-friendly interface for operators to control and monitor the machine’s functions.

Speed Controller

The speed controller adjusts the conveyor belt speed, ensuring bottles move through the labeling machine at the optimal rate for accurate labeling.

Can Be Used for Hundreds of Different Containers

The machine can be used for hundreds of different containers, accommodating various shapes and sizes with ease, making it highly versatile for diverse labeling needs.

Round & Flat Bottles Integrated Labeling Machine for Various Industries

The round & flat bottles integrated labeling machine is designed for use across a variety of industries, including food and beverage, pharmaceuticals, cosmetics, and chemicals.

Watch Our Round & Flat Bottles Integrated Labeling Machine in Action!

See how it efficiently handles both round bottle and flat bottle, providing precise label placement across various industries. Experience its high-speed performance, smooth operation, and versatility in labeling a wide range of products.

Why Choose AUTmachine?

Here’s why you should choose AUTmachine for your round & flat bottles integrated labeling needs

Precision and Versatility

Our machines are designed to handle both round and flat bottles with high precision, ensuring labels are applied correctly every time, regardless of bottle shape.

Reliable Performance

Built for durability and smooth operation, our machines ensure consistent labeling performance even during long production runs or high-speed operations.

User-Friendly Design

The intuitive interface and easy-to-use controls make it simple for operators to quickly adapt to the machine, reducing training time and increasing production efficiency.

Excellent After-Sales Support

We provide comprehensive after-sales services, including quick installation, troubleshooting, and ongoing technical assistance to keep your machine running smoothly.

Round & Flat Bottles Integrated Labeling Machine FAQs

Setup time is minimal and typically takes just a few minutes to adjust for different bottle sizes or labeling configurations.

Yes, the machine can apply labels to both the front and back of the bottles.

Yes, the machine can be easily integrated into a complete production line with other packaging and filling equipment.

Yes, it can label bottles made from various materials, such as plastic, glass, and metal.

Yes, we provide training and support to ensure smooth operation for all users.

Contact us

If standard labeling machines don’t meet your needs, we can manufacture a custom labeling machine based on your production requirements!

Please take a moment to fill out the form on the right with some details about your product labeling needs, so our engineers can understand how to best assist you and provide tailored advice.

Get Your Labeling Machine Quote Here!

Please fill out this form to submit a request for quote(* denotes required fields)