Fully Automatic Vertical Bottle Labeling Machine

Our vertical bottle labeling machine efficiently applies self-adhesive labels to the neck and body of bottles. It’s simple to operate and requires no technical expertise. It’s ideal for labeling products like cosmetic bottles, food cans, and more.

- Support global after-sales

- Automate your labeling process

- Dual-side labeling for bottle neck and body

Home » Bottle Labeling Machine » Vertical Bottle Labeling Machine

Our fully automatic vertical round bottle labeling machine can be equipped with a circumference positioning system for precise labeling at specific locations, as well as a ribbon coder or inkjet printer to print production dates and batch numbers, enabling seamless integration of labeling and coding processes.

Constructed with high-quality materials such as S304 stainless steel and imported aluminum alloys, the machine offers exceptional durability and corrosion resistance. Its user-friendly design includes stable bottle separation using large silicone wheels and a reliable label attachment mechanism for smooth, wrinkle-free application. Furthermore, it can be easily integrated into your existing production line, boosting overall efficiency and productivity.

Fully Automatic Vertical Bottle Labeling Machine Technical Parameters

These specs demonstrate the machine’s precision, efficiency, and adaptability to meet diverse production needs.

|

Model

|

Parameters

|

|---|---|

|

Labeling Accuracy |

+/- 0.1 mm |

|

Labeling Speed |

50 pcs/min |

|

Product Size |

Diameter: φ15mm – φ120mm |

|

Labels Applied |

Single/double sides/wrap-round labeling |

|

Label Size |

Length: 20mm – 300mm |

|

Control System |

PLC control with touch screen interface |

|

Labeling Type |

Self-adhesive roll labels |

|

Equipment Size |

2150mm×1100mm×1440mm |

|

Power Supply |

220V/50HZ |

|

Weight |

222 Kg |

|

Price |

$$$ |

|

Additional Features (Optional) |

Barcode/Date Code Printing/Thermal Transfer Printer/Fiber Optic Sensor/Positioning Function/Transparent Label Sensor |

|

Operation Mode |

Fully automatic |

|

Custom Support |

|

* For more detailed specifications or custom requirements, please contact us directly.

Structure Detailed of Fully Automatic Vertical Bottle Labeling Machine

Understand the key components of the vertical bottle labeling machine and how it enhances your production efficiency. The machine features a sturdy and durable structure, along with an easy-to-operate design, ensuring stable and precise labeling while boosting production efficiency.

Touch Screen

Collection Tray

Amplifier

Filter

Traction

Adjusting Wheel

Recycling

Electric Cabinet

Label Tray

Label Sensor

Sensitive detection andsimple adjustment method.

Product Sensor

It can detect the product and label it ensuring the position of the label and adjusting it.

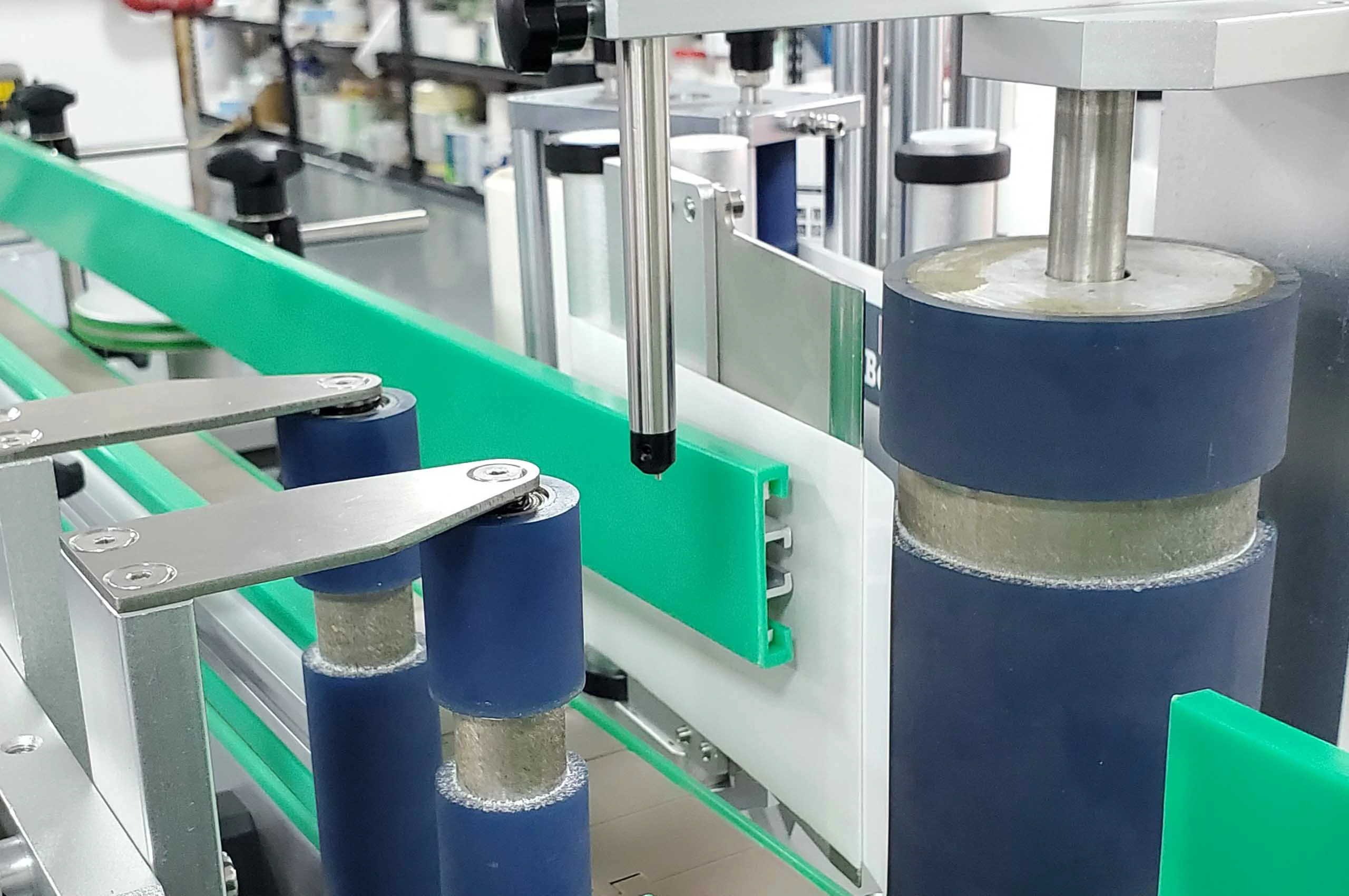

Clamping Device

The clamping device holds the bottle securely in place during the labeling process, ensuring stable positioning and preventing movement

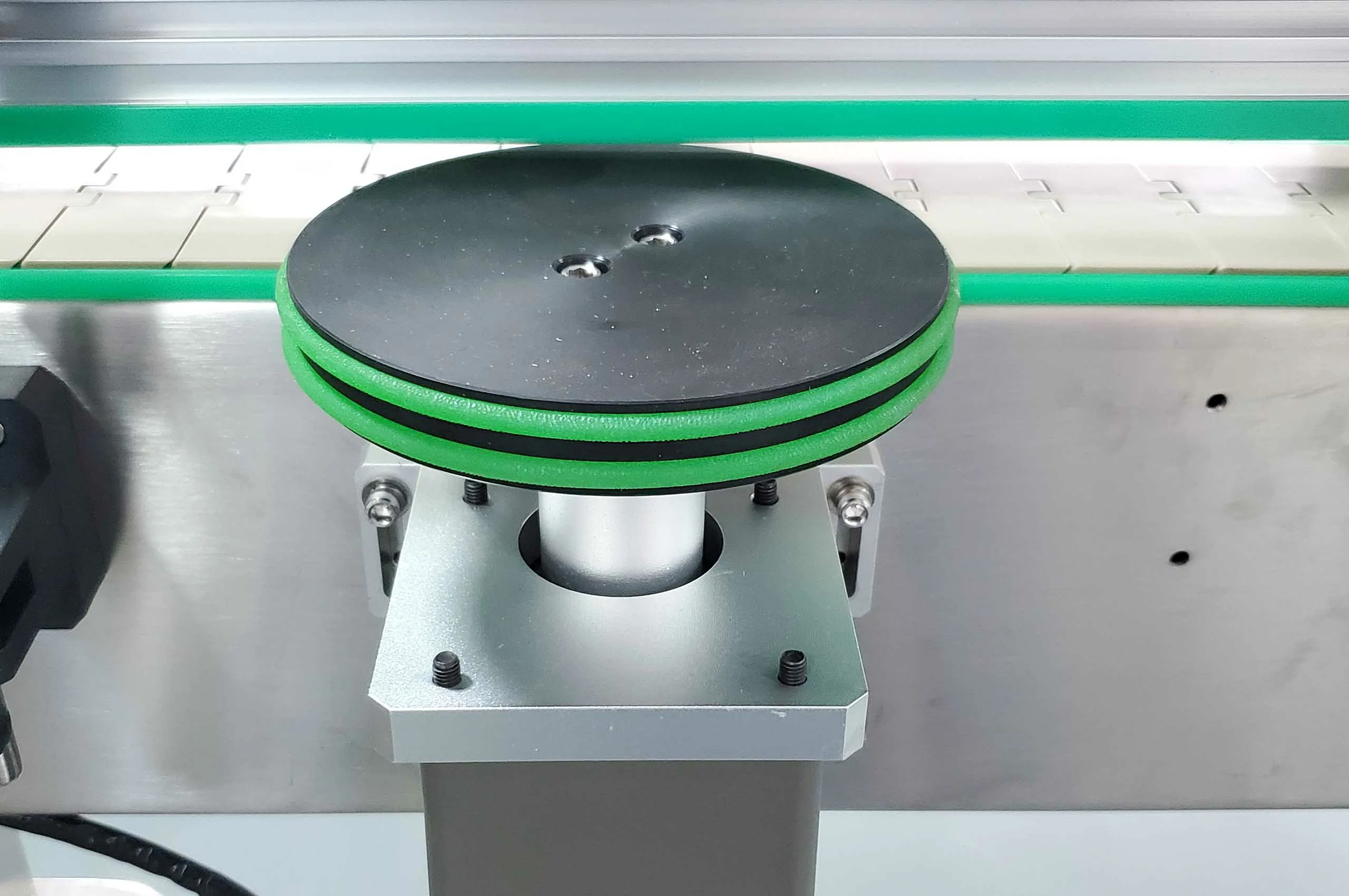

Divide Wheel

The Divide wheel evenly spaces bottles, ensuring precise and accurate label application.

Adjusting Base

The adjusting base under the labeling structure can be rotated with a knob for easy customization based on bottle size and height.

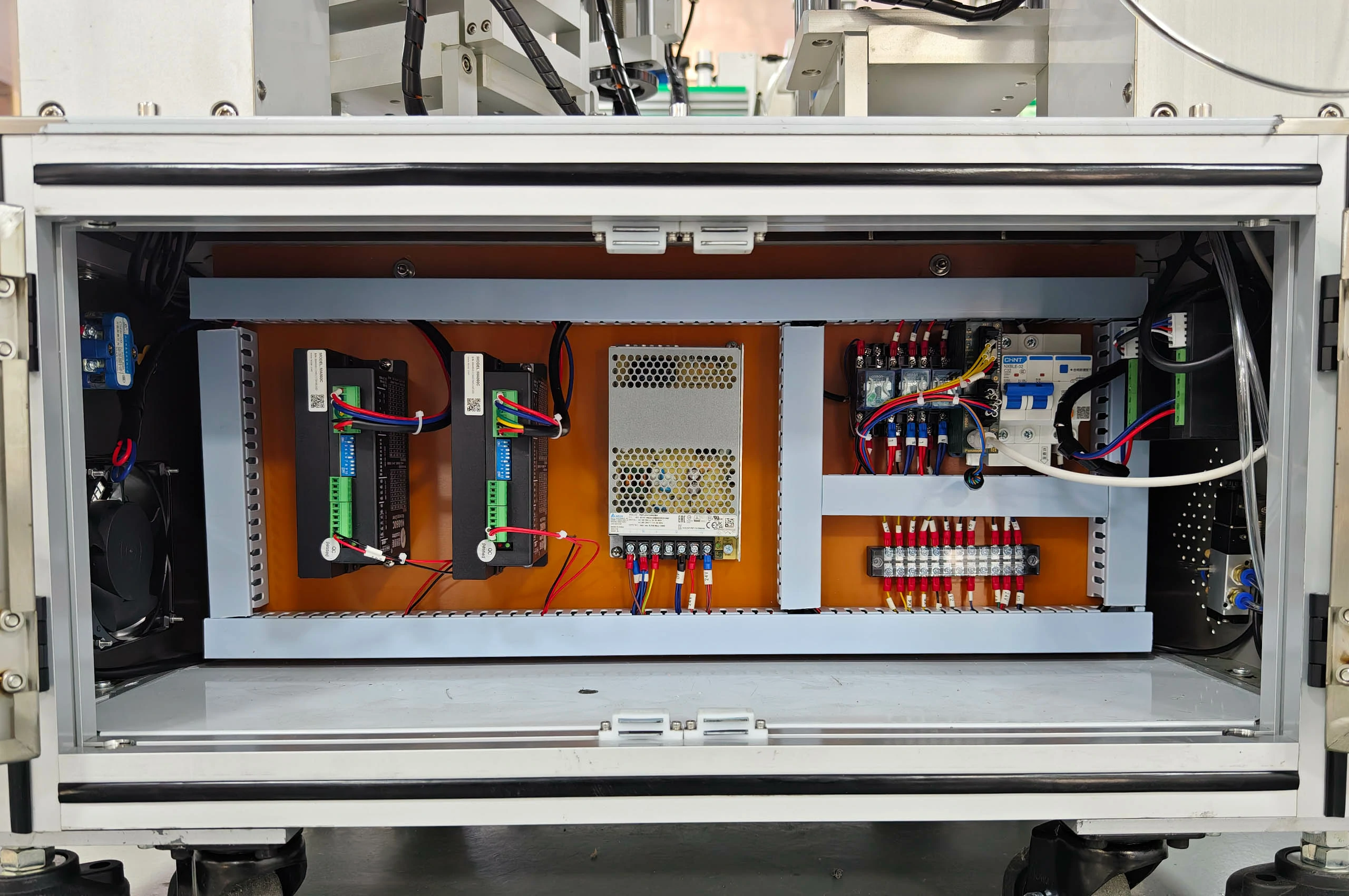

Connect the Electrical

Linking the power supply, control system, and any other necessary electrical connections to the machine.

Speed Regulation

A control system that allows you to adjust the speed of the labeling machine to match production requirements.

Electric Box

Electrical components and control systems fitted with labeling machines provide a centralized location for wiring, switching and circuit protection.

Can Be Used for Hundreds of Different Containers

To showcase the capabilities of our automatic vertical round bottle labeling machines, here are some recent successful applications.

Fully Automatic Vertical Bottle Labeling Machine for Various Industries

From food and beverage to pharmaceuticals, our vertical labeling machine machine meet the precise needs of diverse industries.

Watch Our Vertical Labeling Machine in Action!

See how it effortlessly applies labels with precision and speed to a variety of bottle sizes. In this video, we showcase its smooth operation, quick setup, and ability to handle both single and double label applications.

Why Choose AUTmachine?

At AUTmachine, we offer more than just labeling solutions – we provide a reliable, high-performance machine designed to boost your production efficiency. Here’s why our Vertical Round Bottle Labeling Machine stands out

Customizable

With adjustable label positioning and optional features like a ribbon coder or inkjet printer, our machine can be tailored to meet your specific production needs.

User-Friendl

Designed for ease of operation, the machine requires minimal training, allowing your team to quickly adapt and operate it efficiently, reducing downtime.

Durable and Long-Lasting

Built with high-quality materials like S304 stainless steel and imported aluminum alloys, our machine is resistant to corrosion and wear, offering exceptional longevity.

Efficient Integration

Our machine integrates seamlessly into your production line, optimizing workflow and boosting overall efficiency, maintaining high-quality standards

Fully Automatic Vertical Bottle Labeling Machine FAQs

Yes, we provide comprehensive training materials, including manuals and video tutorials, to ensure smooth operation and maintenance.

We have 200 machines in stock at our factory. For standard equipment, the lead time is typically within 3 days, while for custom (non-standard) equipment, it is usually within 15 days.

Yes, we offer customization options to suit your particular production requirements, including label size, bottle type, and additional features like coding systems.

Our customer support team is available for troubleshooting, and we provide repair or replacement for faulty parts covered by the warranty.

Contact us

If standard labeling machines don’t meet your needs, we can manufacture a custom labeling machine based on your production requirements!

Please take a moment to fill out the form on the right with some details about your product labeling needs, so our engineers can understand how to best assist you and provide tailored advice.

Get Your Automatic Labeling Machine Quote Here!

Please fill out this form to submit a request for quote(* denotes required fields)