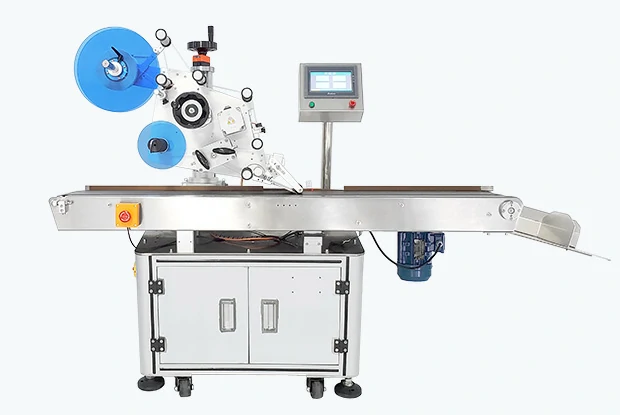

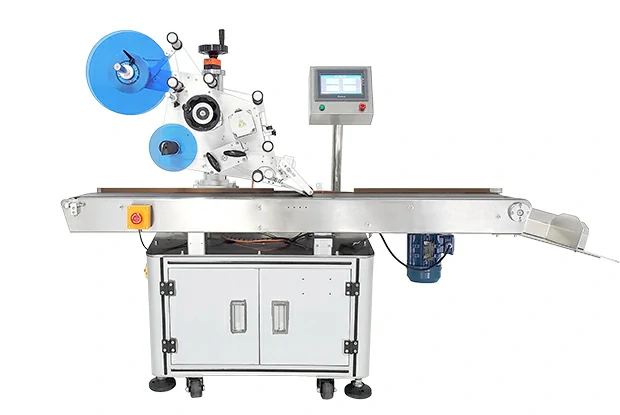

Fully Automatic Flat Labeling Machine

A fully automatic flat labeling machine is designed for labeling large products and flat items with a wide range of specifications, offering high-speed, precise, and efficient labeling without manual intervention.

- Adjustable for different product sizes

- No manual intervention required

- Easily connects to existing production lines

Home » Flat Labeling Machine » Automatic Flat Labeling Machine

Our fully automatic flat labeling machine is designed for labeling the flat surfaces or adhesive films of various items such as books, folders, boxes, cartons, and more. By changing the labeling mechanism, it can also handle labeling of uneven surfaces.

Working Principle: The sensor detects the passing product and sends a signal to the labeling control system. The signal is processed by the PLC, and at the appropriate time, the label is dispensed and applied to the preset position on the product. As the product moves through the labeling unit, the label is firmly applied, completing the labeling process.

Operation Process: Place the product (can be connected to a production line) → Product transportation (automatically) → Product alignment (automatically) → Product detection (automatically) → Labeling (automatically) → Label application (automatically) → Collection of labeled products.

Automatic Flat Labeling Machine Technical Parameters

To give you a clearer idea of what our automatic flat labeling machine can do, here are its essential technical parameters. Designed to meet diverse labeling requirements, this machine ensures outstanding performance, no matter the product size or shape.

|

Model

|

Parameters

|

|---|---|

|

Labeling Accuracy |

+/- 1mm |

|

Labeling Speed |

80 pcs/min |

|

Product Size |

Length: 40mm ~ 400mm Width: 40mm ~ 200mm Height: 0.5mm ~ 150m |

|

Label Size |

Length: 6mm ~ 300mm width (bottom paper width) : 15mm ~ 130mm |

|

Suitable Label Inner Diameter |

Ø76mm |

|

Suitable Label Outer Diameter |

Ø300mm |

|

Control System |

PLC with touch screen |

|

Machine Material |

Stainless steel |

|

Equipment Size |

1920mm×830mm×1350mm |

|

Power Supply |

220V/50HZ |

|

Weight |

188.5Kg |

|

Price |

$$$ |

|

Additional Features (Optional) |

Printer for batch number, production date, or other information |

|

Custom Support |

|

Structure Detailed of Automatic Flat Labeling Machine

The labeling speed and labeling position of our automatic flat labeling machine can be adjusted, single labeling can also be continuous labeling, easy to operate. Below are the key components that make up the structure:

Label Roller

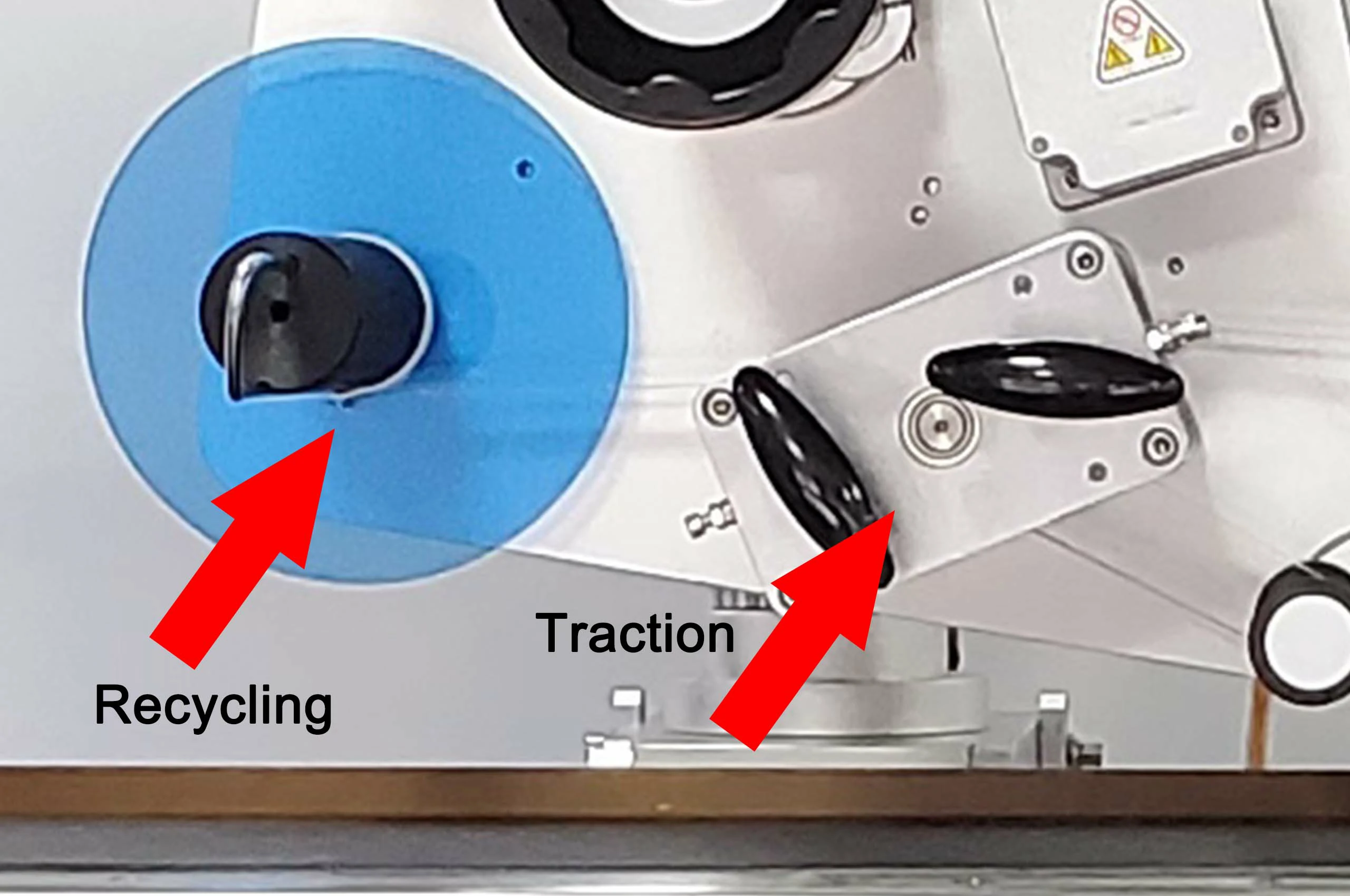

Traction

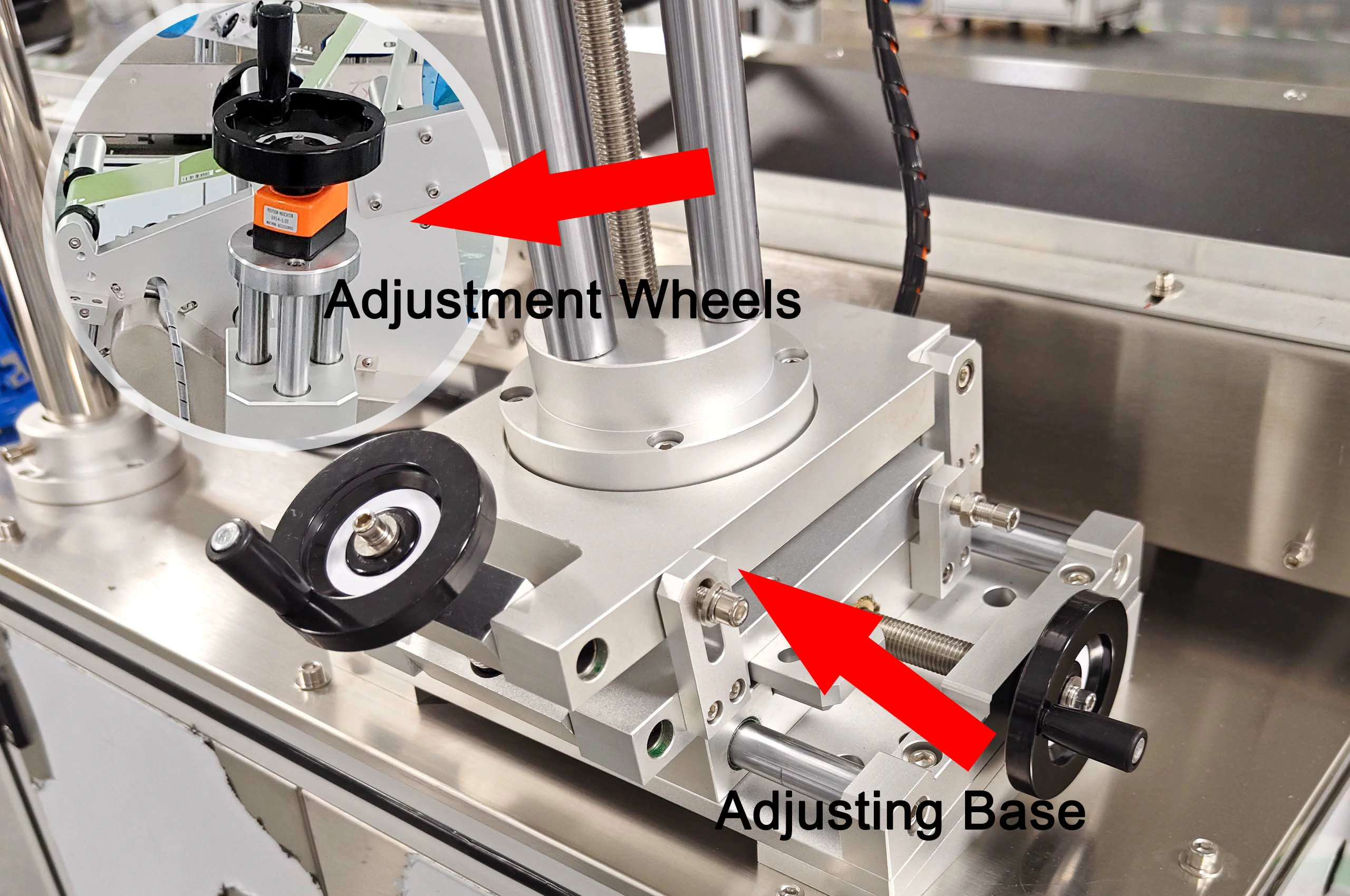

Adjusting Wheel

Recycling

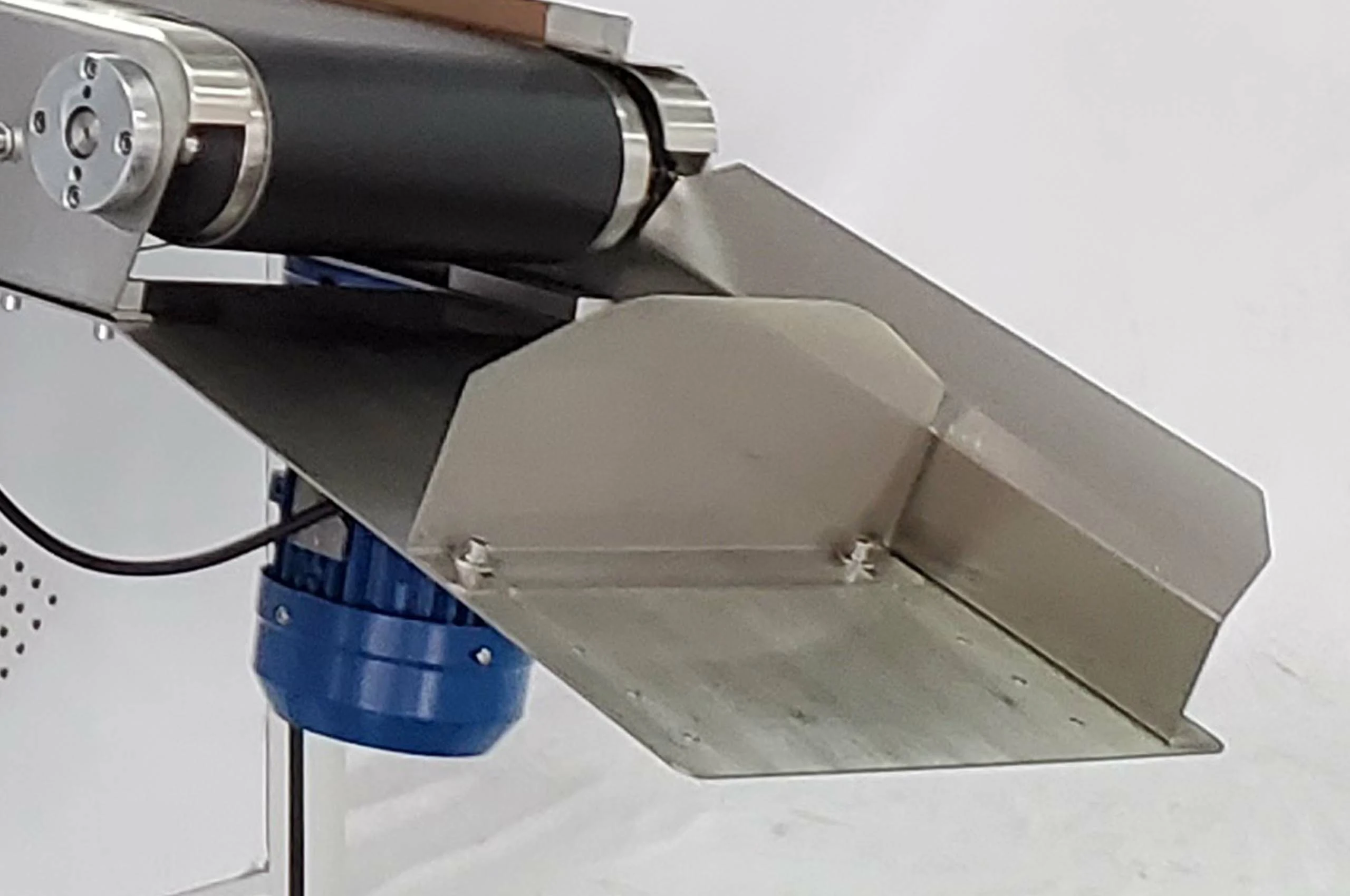

Collection Tray

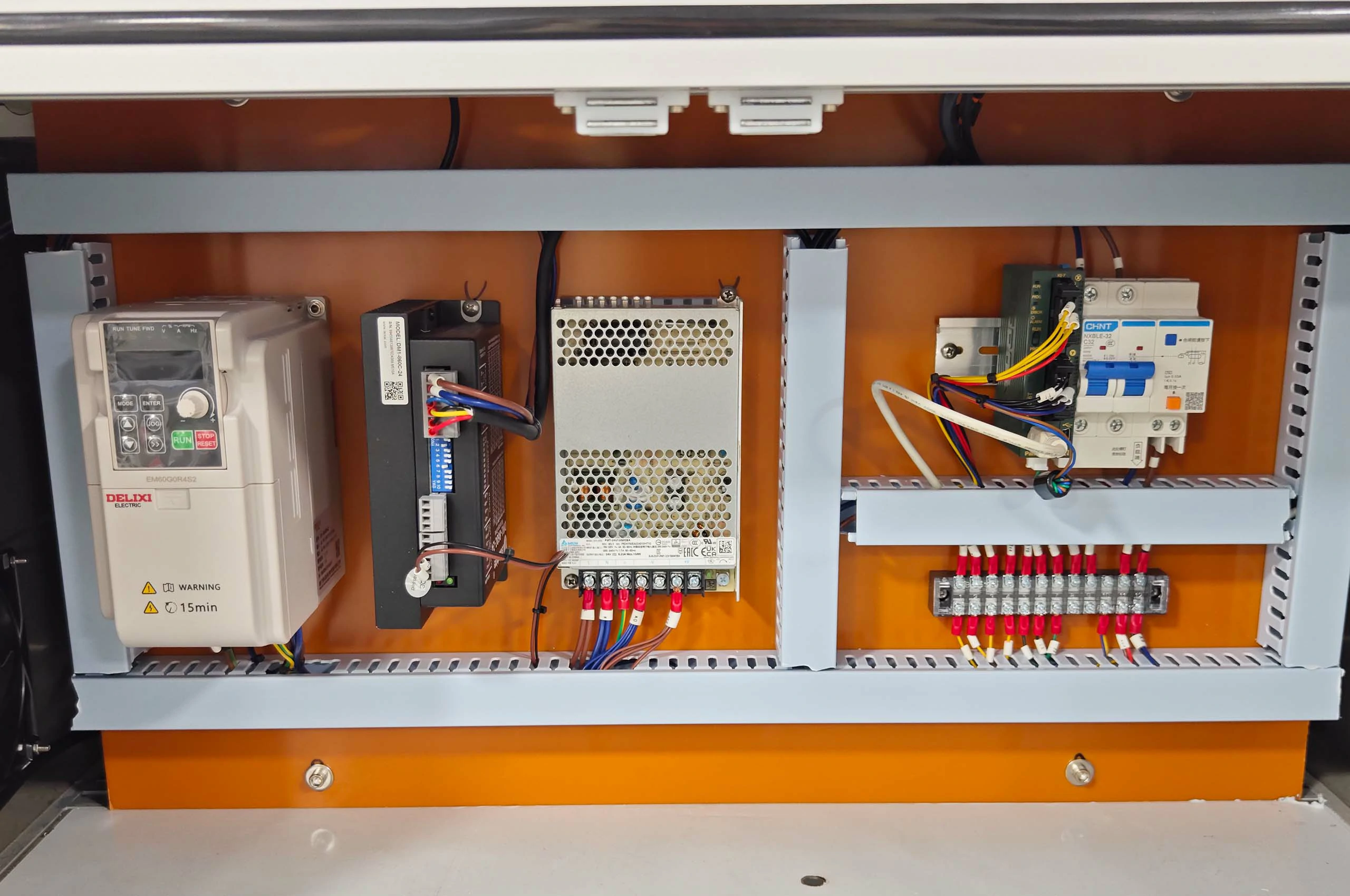

Electric Cabinet

Touch Screen

Emergency Button

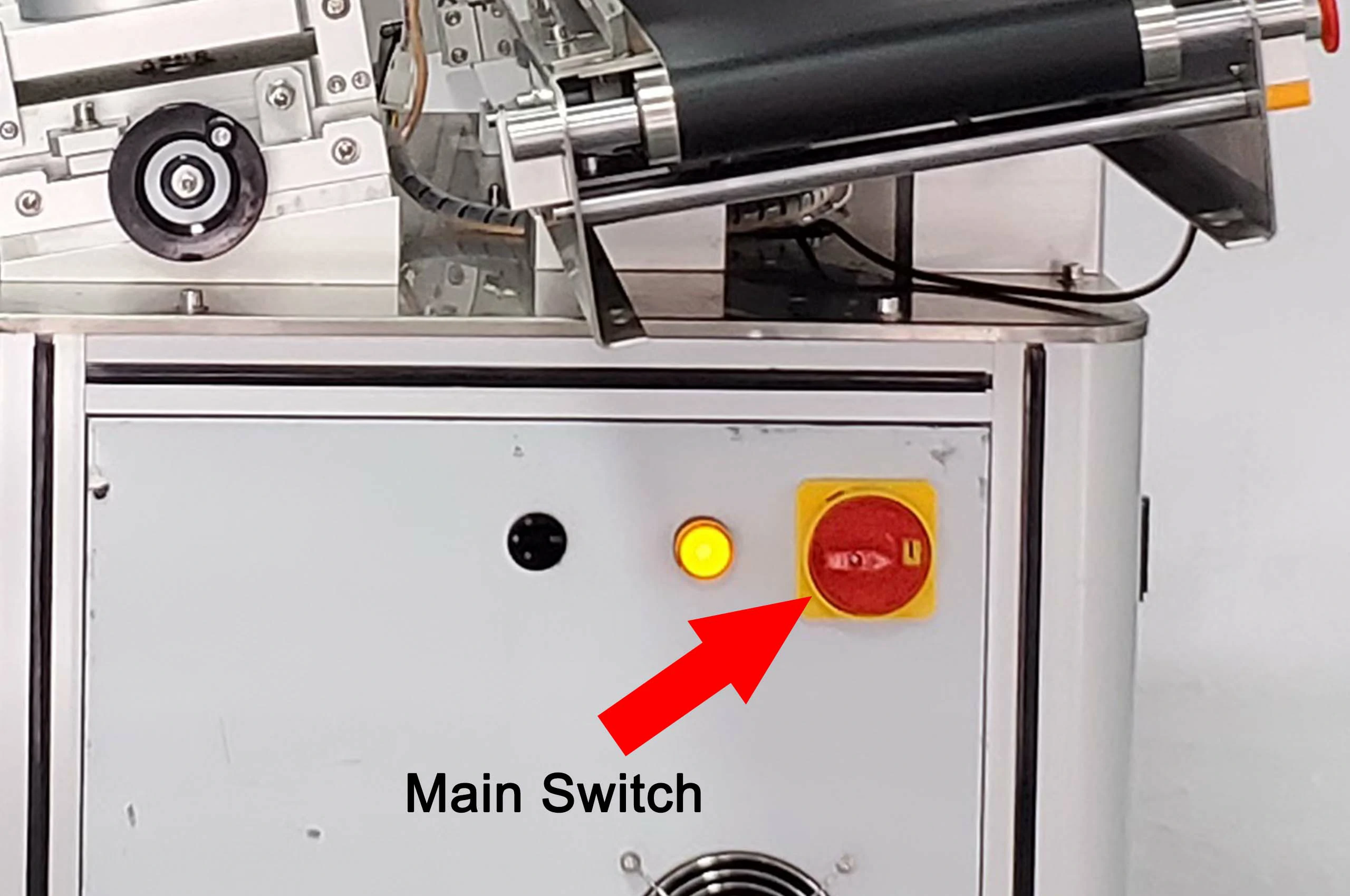

Main Switch

Pressing Device

Label Tray

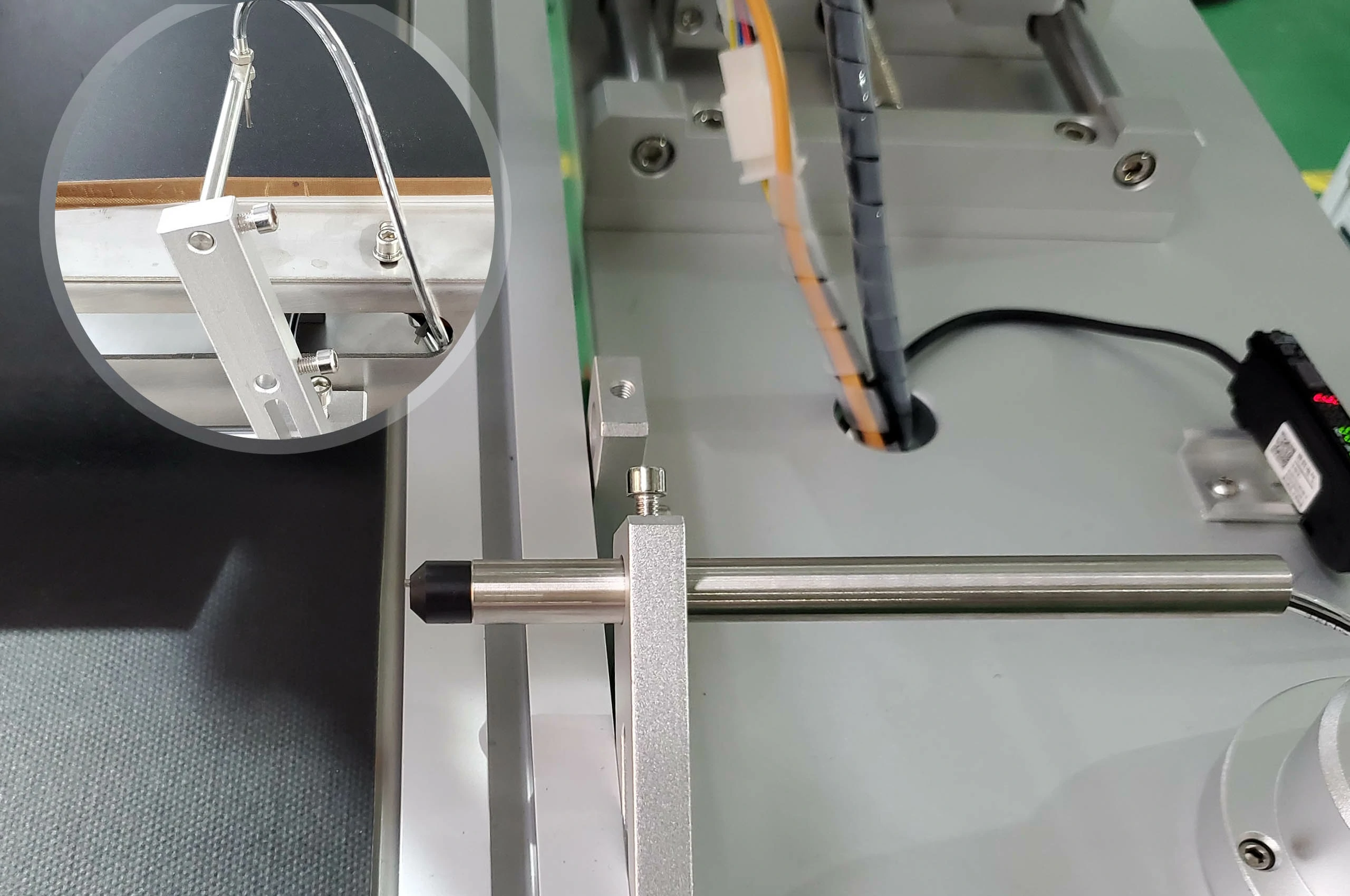

Label Sensor

It ensures accurate alignment by continuously monitoring the label’s position, reducing the risk of label misplacement

Product Sensors

Detects the presence of products, triggers the labeling process, and ensures correct label positioning with minimal error.

Recycling & Traction

Collects scrap and provides stable traction, preventing clogging and keeping the production line clean.

Adjusting Mechanism

Allows precise adjustments for height, position, and angle, ensuring accurate labeling for various product sizes and shapes.

Pressing Device

Ensures products remain stable during labeling, preventing movement or misalignment for precise label application.

Collection Tray

Collects labeled products after the labeling process, facilitating smooth workflow and easy removal of finished items.

Touch Screen

Provides a user-friendly interface for controlling and monitoring machine operations, enabling easy adjustments and real-time status updates.

Main Switch

Controls the overall power supply to the machine, serving as the primary on/off control for safe operation.

Electric Cabinet

Houses the electrical components and control systems.

Can Be Used for Hundreds of Different Products

Versatile design allows the machine to handle a wide range of product shapes and sizes, making it ideal for various industries and applications.

Automatic Flat Labeling Machine for Various Industries

Efficient and versatile, our automatic flat labeling machine handles a wide range of products, offering precise labeling for industries like food, pharmaceuticals, and cosmetics.

Watch Our Automatic Flat Labeling Machine in Action!

See how our automatic flat labeling machine works in real-time, delivering high-speed, precise labeling for various products and industries. Watch the efficiency and accuracy in action!

Why Choose AUTmachine?

At AUTmachine, we offer more than just a labeling machine – we provide a solution designed for efficiency, precision, and long-term reliability.

Easy Operation

The touchscreen interface offers an intuitive, user-friendly experience, allowing easy adjustments and monitoring of the labeling process.

Cost-Effective

We provide an affordable solution without compromising on quality. The semi-automatic design ensures you get high performance at a lower cost, ideal for small to medium-scale production.

User-Friendly Operation

With simple controls and easy setup, our labeling machines are designed for ease of use. Your team can quickly learn and operate the machine, improving overall productivity.

One-Year Warranty Guarantee

We offer a one-year warranty on our labeling machines against defects. If any parts are faulty or issues arise from manufacturing errors, we’ll replace or repair them. The warranty doesn’t cover damage from misuse or accidents.

Automatic Flat Labeling Machine FAQs

It can label a wide variety of products, including flat, rectangular, and irregularly shaped items such as boxes, books, and containers.

Yes, the automatic flat labeling machine can easily be integrated into your existing production line for a seamless operation.

We offer flexible purchasing options, and there is typically no minimum order quantity. Contact us for custom requirements.

Yes, the machine can be equipped with an optional coding system such as a thermal transfer printer or inkjet printer for printing batch numbers, production dates, and other variable information.

Contact us

If standard labeling machines don’t meet your needs, we can manufacture a custom labeling machine based on your production requirements!

Please take a moment to fill out the form on the right with some details about your product labeling needs, so our engineers can understand how to best assist you and provide tailored advice.

Get Your Labeling Machine Quote Here!

Please fill out this form to submit a request for quote(* denotes required fields)