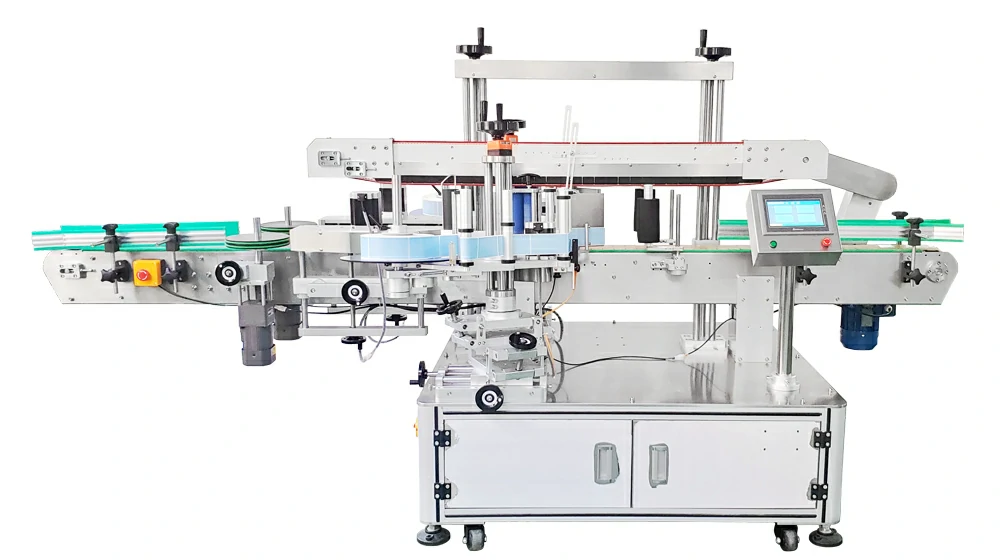

Fully Automatic Double Side Labeling Machine

It is suitable for single-side and double-side labeling of flat bottles and square bottles, and double labeling on both sides improves production efficiency. With no label automatic correction and label automatic detection function, avoid waste label and missing label.

- Intelligent control, automatic photoelectric tracking

- Can be single production, can also be connected to the production line

- The machine is made of stainless steel and high-grade aluminum alloy

Home » Fully Automatic Double Side Labeling Machine

This machine applies both the front and back labels of the bottle simultaneously, and is compatible with bottles of different shapes. The machine can be adjusted according to the shape of the bottle to adapt. Can automatically separatethe distance between bottles, automatically detect,and intelligently control.

Working principle: The sensor detects that the product has passed, returns the signal to the labeling control system, and the control system controls to send the label and attach it to the product to be labeled at the appropriate position, the product flows through the labeling device, the label is attached to the product, and the attaching action of a label is completed.

Operation process: Put the product (can be connected to the pipeline) one > product delivery -> product separation -> labeling (equipment automatic realization)-> Collection of labeled products

Automatic Double Side Labeling Machine Technical Parameters

Learn the key technical parameters of our automatic double side labeling machine. It is able to meet the labeling needs of a variety of industries, from food and beverage to pharmaceutical and cosmetics.

|

Model

|

Parameters

|

|---|---|

|

Labeling Accuracy |

+/- 0.1mm |

|

Labeling Speed |

160 pcs/min |

|

Product Size |

Length: 20mm ~ 250mm Width: 30mm ~ 90mm Height: 60mm ~ 280mm |

|

Labels Applied |

2 (front & back) |

|

Label Size |

Length: 20mm ~ 300mm width (bottom paper width) : 20mm ~ 170mm |

|

Control System |

PLC control with touch screen interface |

|

Machine Size |

3020mm×1560mm×1570mm |

|

Power Supply |

220V/50HZ |

|

Weight |

473Kg |

|

Price |

$$$ |

|

Additional Features (Optional) |

Barcode/Date Code Printing/Thermal Transfer Printer/ |

|

Custom Support |

|

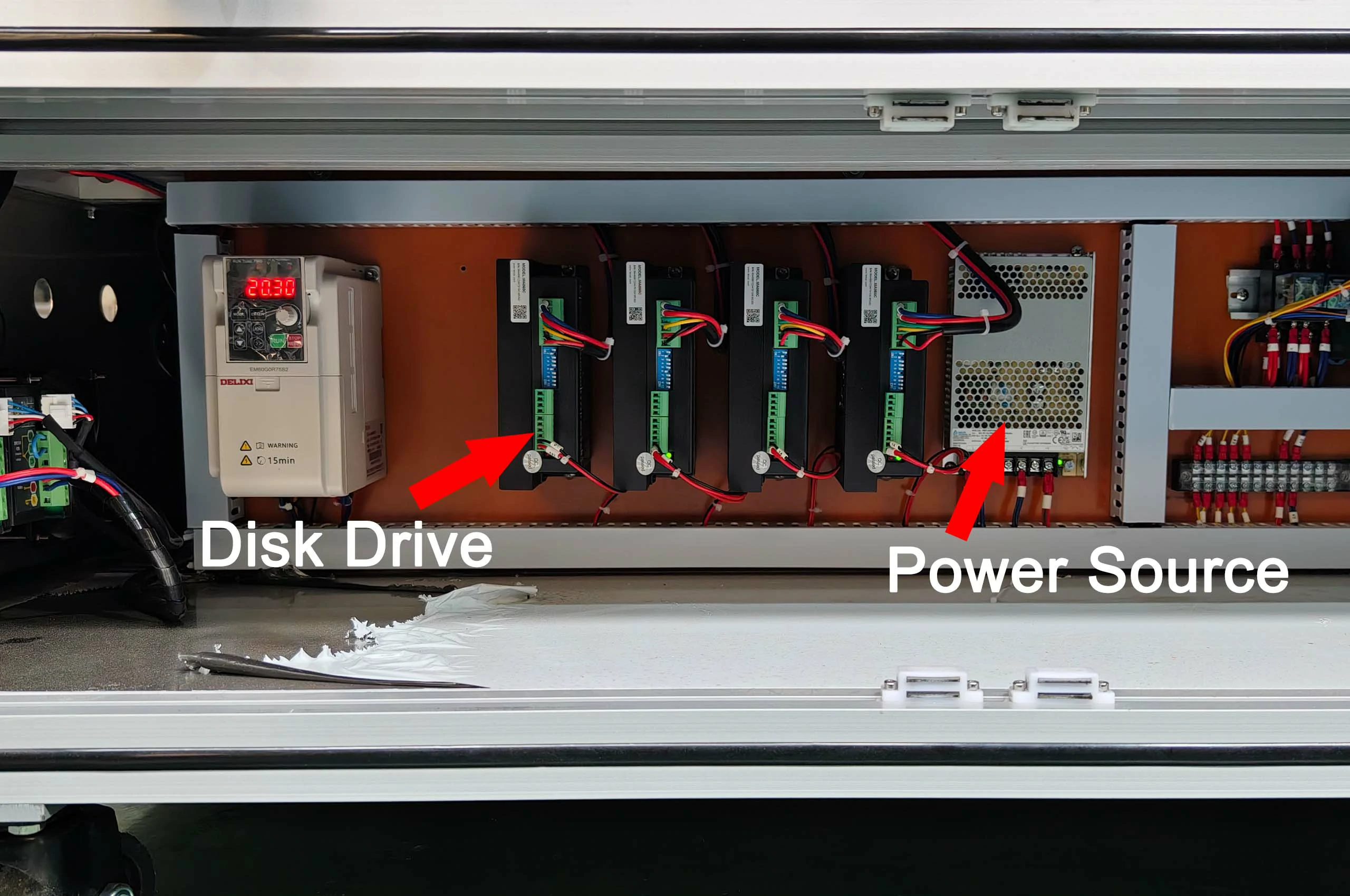

Structure Detailed of Automatic Double Side Labeling Machine

Discover the key components of our automatic double side labeling machines.

Pressing Device

Spacing Wheel

Guide Device

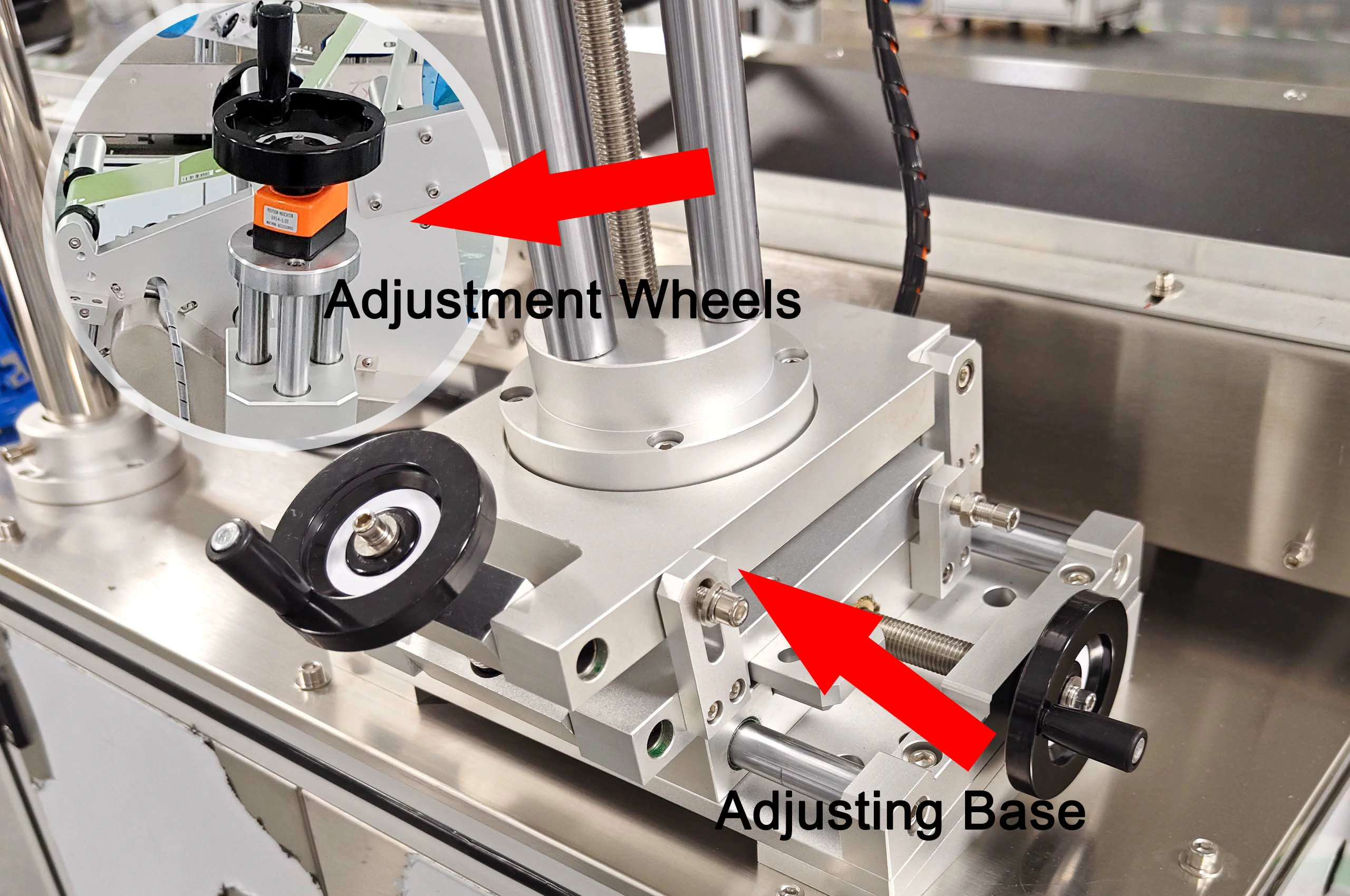

Adjusting the Base

Electric Cabinet

Touch Screen

Emergency Button

High Speed Motor

Labeling Position

Adjusting Wheel

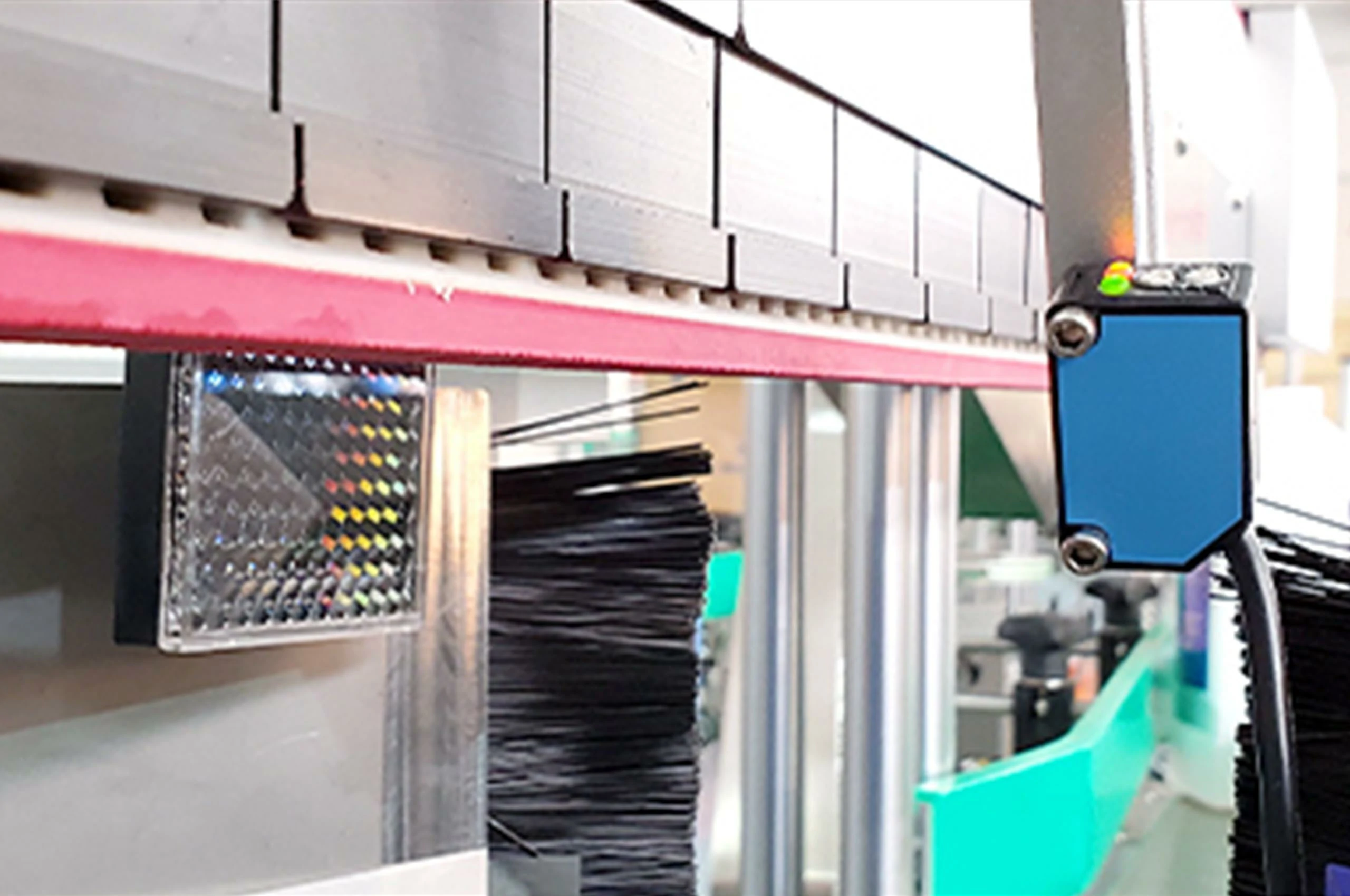

Label Sensor

The purpose is to detect the presence and location of the tag. Make sure the label is on the product at the right time and place.

Product Senson

When the product is moved on the production line, the product is detected and the labeling indication is given.

Recycling & Traction

Tighten the label, collect peeling paper or scrap, prevent buildup and clogging, and keep the production line clean.

Touch Screen

Provides a user-friendly interface for controlling and monitoring machine operations, enabling easy adjustments and real-time status updates.

Adjusting Mechanism

Allows precise adjustments for height, position, and angle, ensuring accurate labeling for various product sizes and shapes.

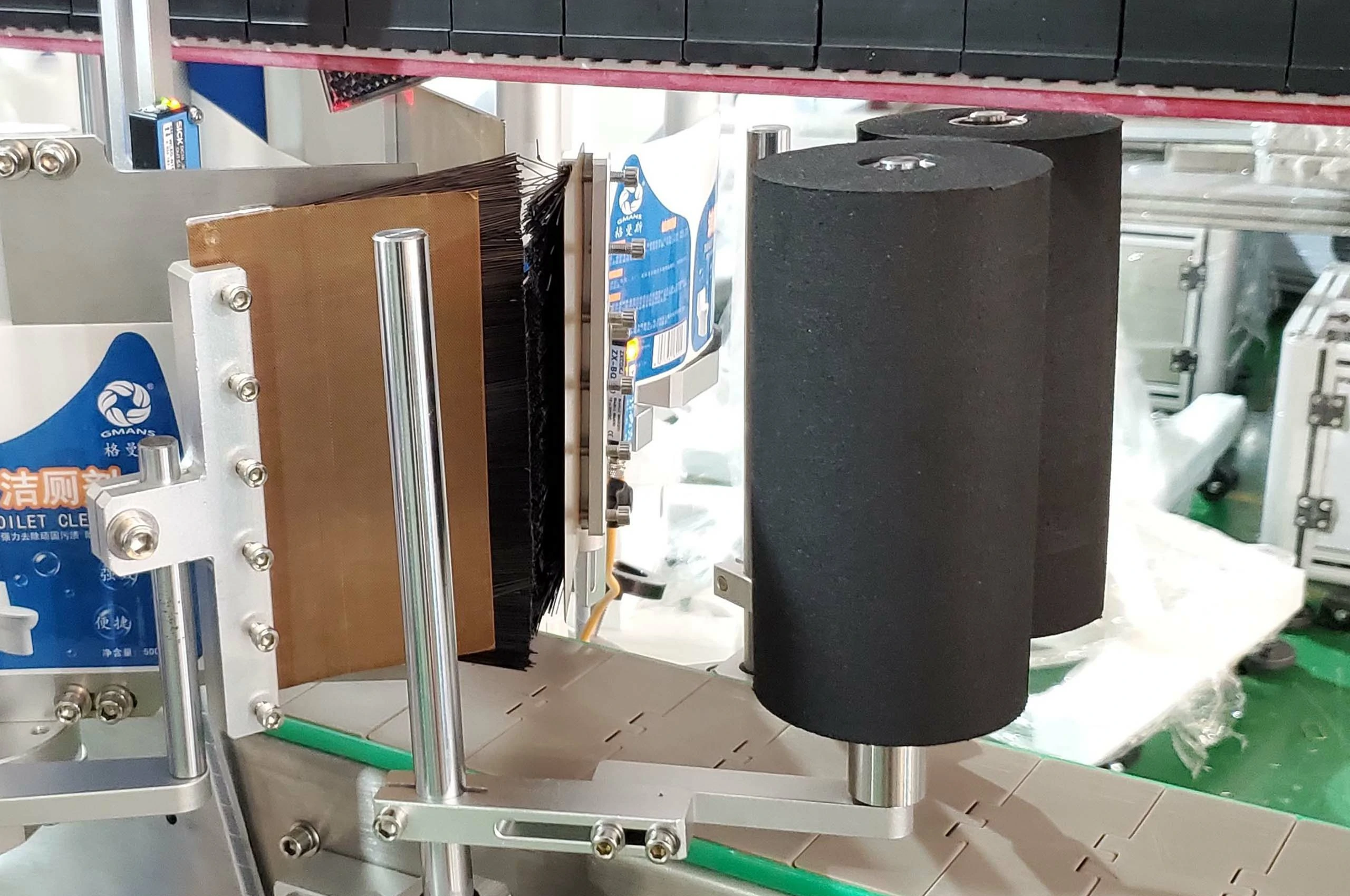

Spacing Wheel

It ensures that the product are spaced evenly as they move through the labeling station, allowing for precise and accurate label application.

Guide Device

The product that passes through the spacer wheel is uniformly guided to the labeling position.

Labeling Position

The label is separated from the label paper, transported to the product to be labeled, and the label is evenly attached to the product to prevent wrinkles, bubbles, or misalignment.

Electric Cabinet

Houses the electrical components and control systems.

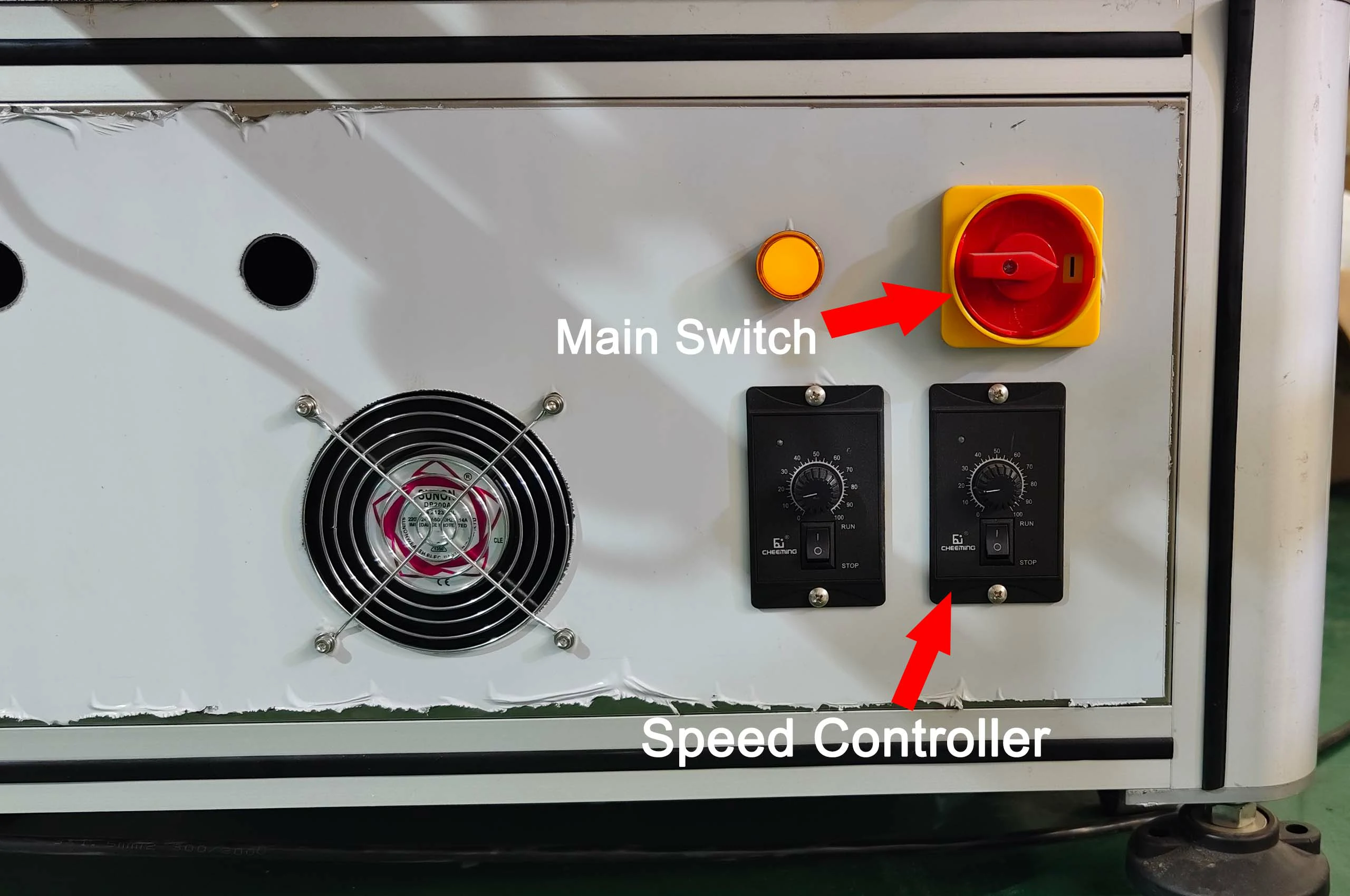

Speed Controller and Main Switch

The speed controller is responsible for adjusting the device speed. The main switch controls the power supply of the whole machine.

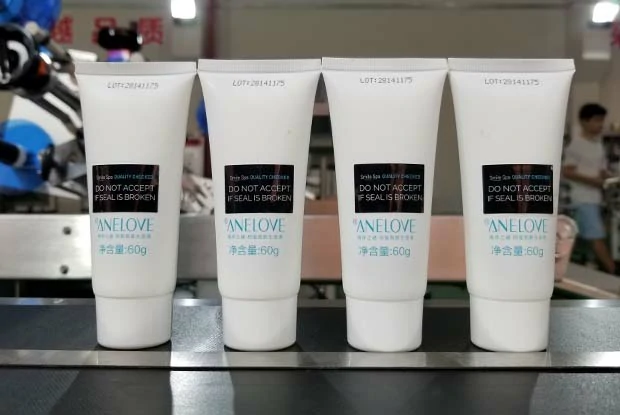

Can Be Used for Hundreds of Different Containers

This labeling machine can be used for hundreds of different containers, offering flexibility for various industries and packaging types, making it a versatile solution for diverse labeling needs.

Automatic Double Side Labeling Machine for Various Industries

From food and beverage to pharmaceuticals, our semi automatic round bottle labeling machine meet the precise needs of diverse industries.

Watch Our Automatic Double Side Labeling Machine in Action!

See how it efficiently applies labels on both sides of your containers, ensuring precision and speed for high-volume production lines.

Why Choose AUTmachine?

At AUTmachine, we offer more than just a labeling machine – we provide a solution designed for efficiency, precision, and long-term reliability.

Precision Labeling

Achieve perfect label placement every time on both sides of the product, with minimal adjustment. Our labeling machines offer high accuracy and flexibility for various product sizes and label types.

Cost-Effective

We offer an affordable solution without compromising on quality. The fully automatic design delivers high performance and efficiency, making it ideal for medium to large-scale production lines at a competitive price.

User-Friendly Operation

With intuitive controls and simple setup, our fully automatic machines are designed for effortless operation. Your team can quickly learn to operate the system, improving overall productivity and reducing training time.

One-Year Warranty Guarantee

Our fully automatic double-side labeling machines come with a one-year warranty against defects. If any parts are faulty or issues arise from manufacturing errors, we will replace or repair them.

Automatic Double Side Labeling Machine FAQs

It is a machine designed to apply labels on both sides of a product automatically, offering high efficiency for large-scale production.

Yes, it can label cylindrical, square, and oval products with adjustable components to fit different shapes.

Yes, the machine is designed to be easily integrated into existing production lines with minimal disruption.

Installation is quick, usually completed within 1-2 days, with full support provided for setup and calibration.

Contact us

If standard labeling machines don’t meet your needs, we can manufacture a custom labeling machine based on your production requirements!

Please take a moment to fill out the form on the right with some details about your product labeling needs, so our engineers can understand how to best assist you and provide tailored advice.

Get Your Automatic Labeling Machine Quote Here!

Please fill out this form to submit a request for quote(* denotes required fields)