Hot Melt Glue Labeling Machine

A professional bottle labeling machine for hot melt adhesive labels, with a maximum speed of 250 bottles/min. The number of workstations can be customized to support more needs. Paired next to the automatic assembly line,suitable for large-scale production.

- Two versions for round and square bottles

- Ensures durable, long-lasting label application

- High-speed operation with minimal upkeep

- One-to-one video chat support, install & debug video

Home » Hot Glue Labeling Machine

Hot Melt Glue Labeling Machine Technical Parameters

This machine is specifically designed to deliver precise and efficient labeling on round and square bottles using hot melt adhesive, ensuring strong adhesion and minimal downtime. To help you better understand the capabilities and performance of our hot melt glue labeling machine, we’ve outlined its key technical parameters.

|

|

|

Table Header

|

|---|---|---|

|

Name |

Round Bottle Hot Melt Glue Labeling Machine |

Square Bottle Hot Melt Glue Labeling Machine |

|

Labeling Accuracy |

+/- 1mm |

+/- 1mm |

|

Labeling Speed |

1200 to 1500 per hour |

1200 to 1400 per hour |

|

Maximum Labeling Speed |

The maximum label output speed is 100 meters per minute |

The maximum label output speed is 100 meters per minute |

|

Conveyor Speed |

30 meters/min |

25 meters/min |

|

Speed Adjustment |

Frequency inverter control |

Frequency inverter control |

|

Maximum Label Width (Height) |

140mm |

180mm |

|

Maximum Label Length |

430mm |

750mm |

|

Maximum Label Outer Diameter |

600mm |

600mm |

|

Core Diameter |

152mm |

152mm |

|

Adhesive Type |

Hot melt glue, applied only at both ends of the label |

Hot melt glue, applied only at both ends of the label |

|

Glue Temperature |

120–160°C |

120–160°C |

|

Label Types |

OPP film labels, paper-plastic composite film labels, paper labels |

OPP film labels, paper-plastic composite film labels, paper labels |

|

Labeling Stations |

12 stations for round bottle labeling |

Single station for square bottle labeling |

|

Labeling Product Type |

Round bottles |

Square bottles |

|

Power Supply |

Three-phase 380V, 50Hz, 8000W |

Three-phase 380V, 50Hz, 8000W |

|

Machine Length |

3100mm (conveyor length: 2990mm, adjustable to customer’s production line dimensions) |

3100mm (conveyor length, adjustable to customer’s production line dimensions) |

|

Main Machine Dimensions |

1650mm (L) x 1350mm (W) x 2100mm (H) |

4650mm (L) x 1650mm (W) x 1650mm (H) |

|

Conveyor Height |

1050±30mm |

1050±30mm |

|

Total Weight |

Approx. 2000kg |

Approx. 1500kg |

|

Price |

$$$ |

$$$ |

|

Custom Support |

|

|

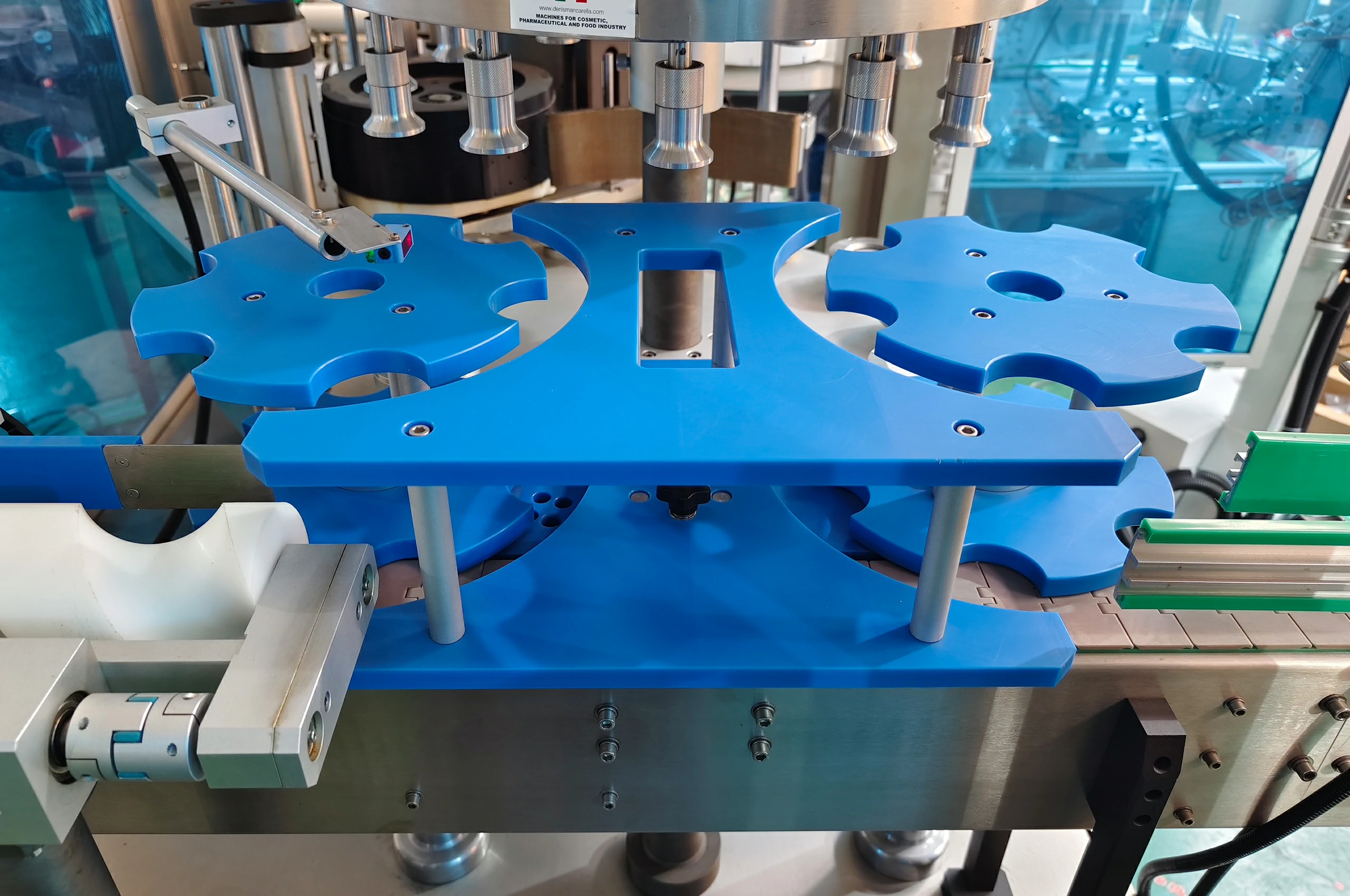

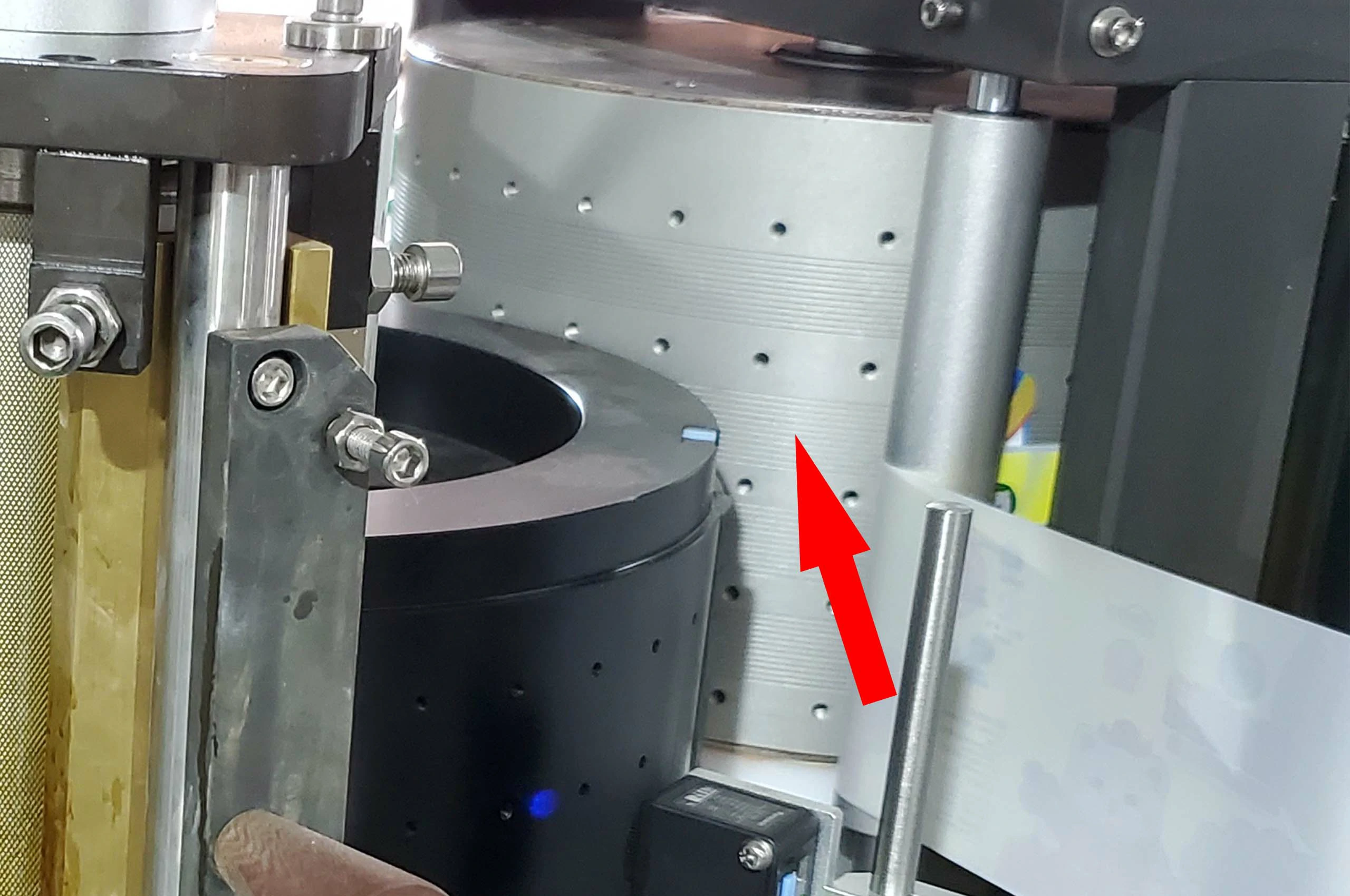

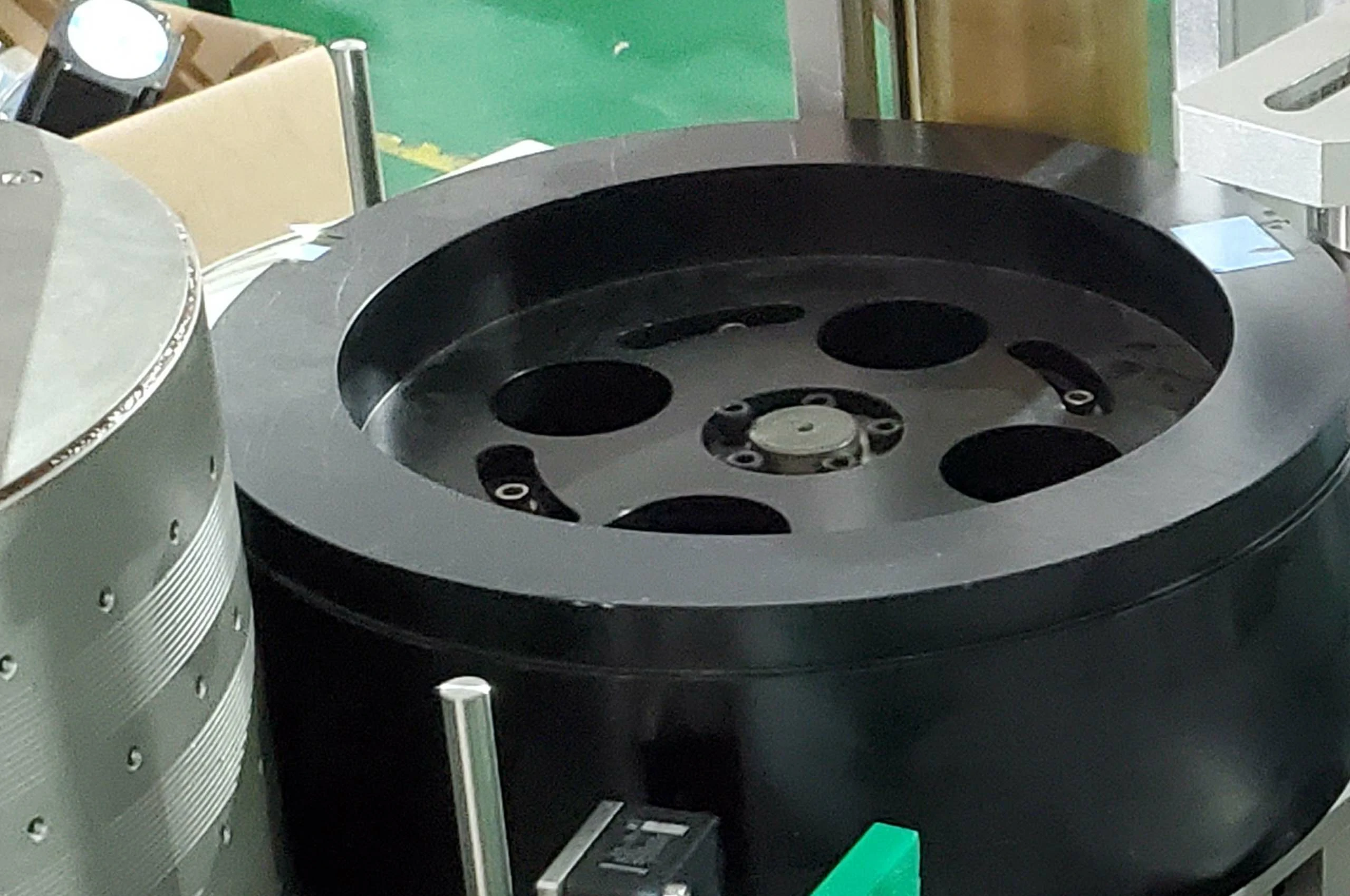

Structure Detailed of Hot Melt Glue Labeling Machine

With its user-friendly interface and customizable settings, it can easily adapt to various production needs, optimizing your labeling process for high-speed and high-quality results.

Round Bottle Hot Melt Glue Labeling Machine

Label Roller

High Speed Motor

Adjusting Wħeel

Electric Cabinet

Touch Screen

Main Switch

Label Tray

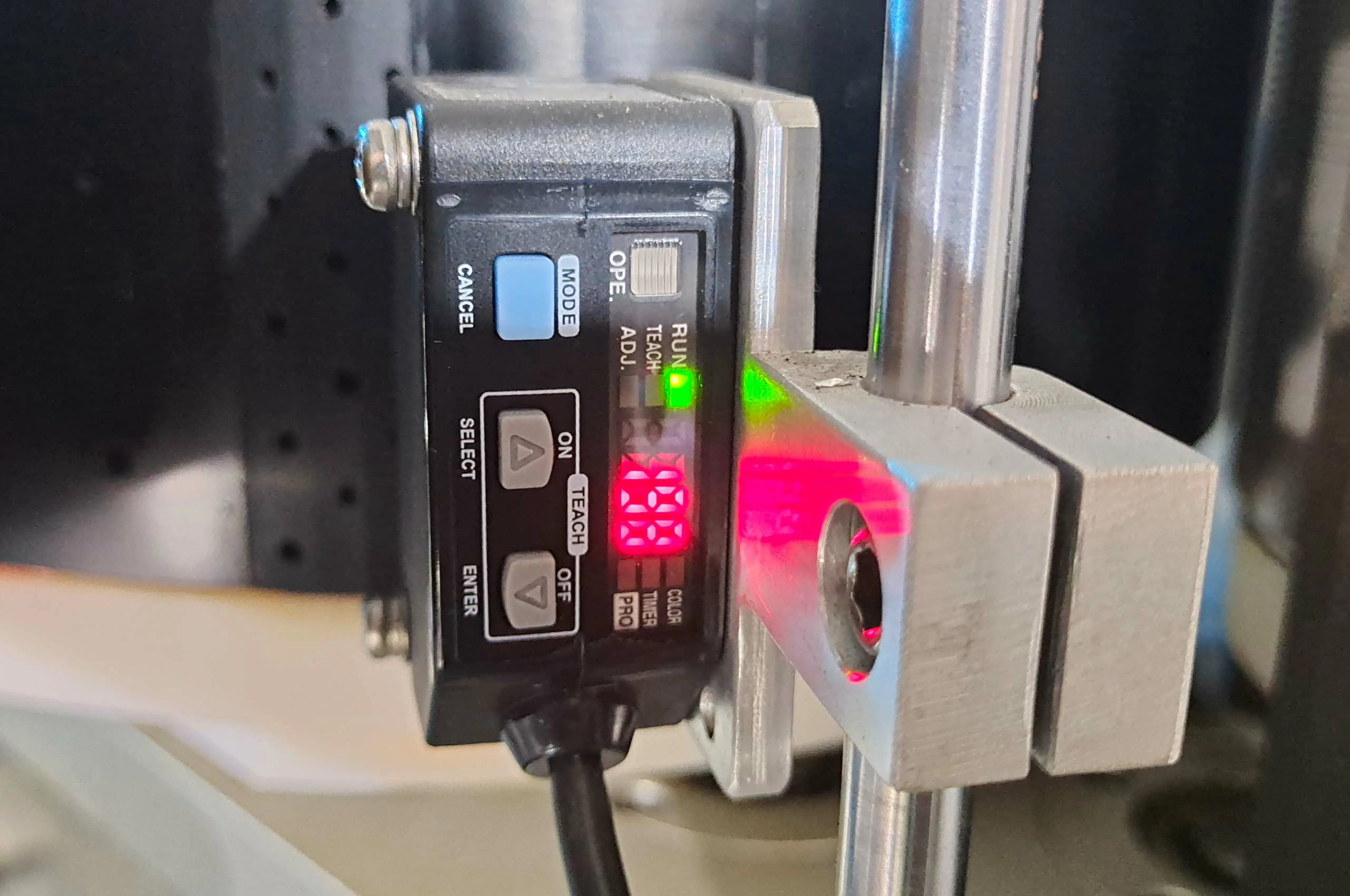

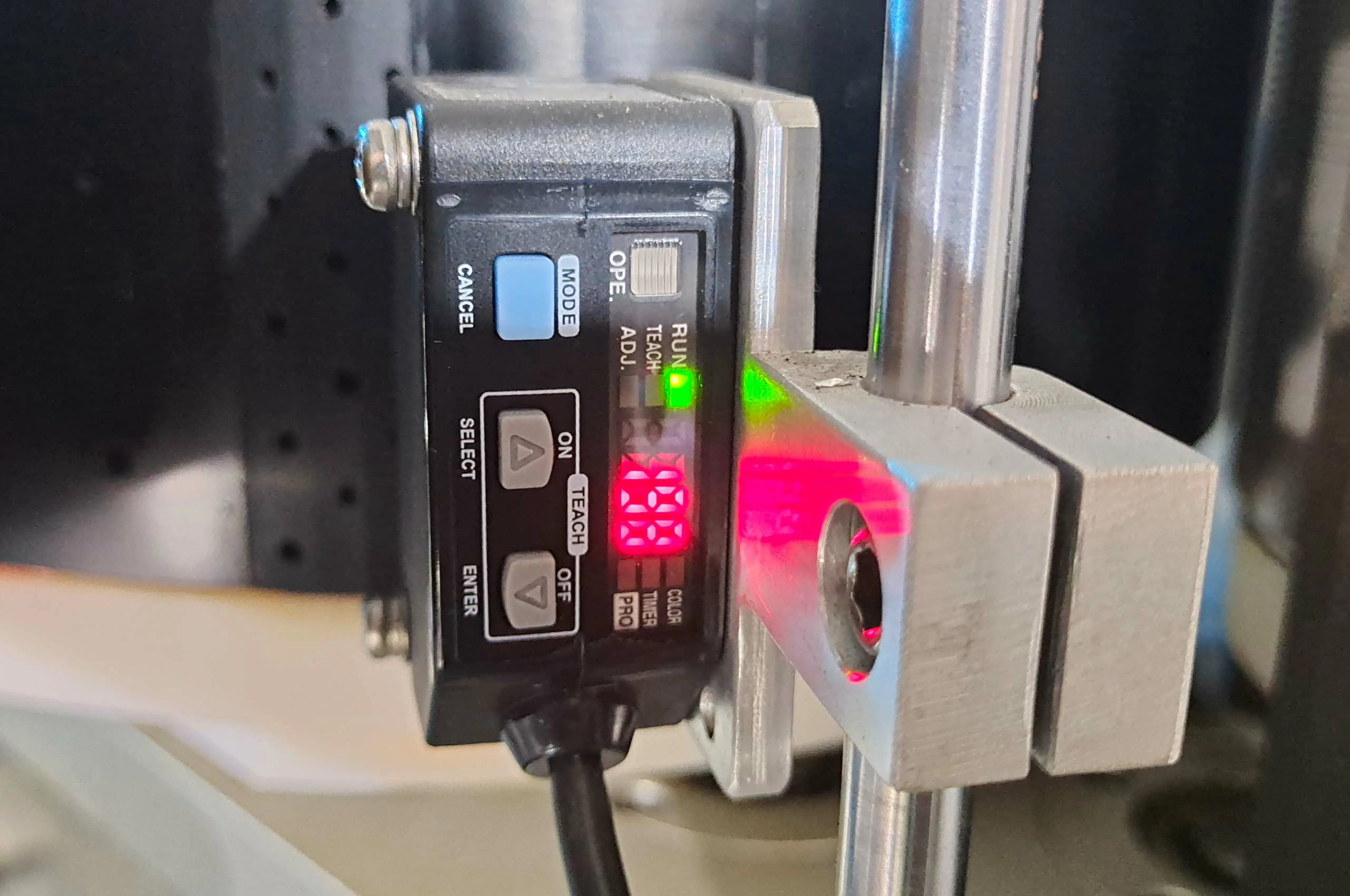

Sensor

It ensures precise alignment and accurate label placement by automatically triggering the labeling process when a bottle is in the correct position.

Remote Control

The remote control system allows for easy and convenient operation of the labeling machine from a distance.

Temperature Control Meter

By accurately monitoring and adjusting the temperature, it prevents overheating or insufficient heating.

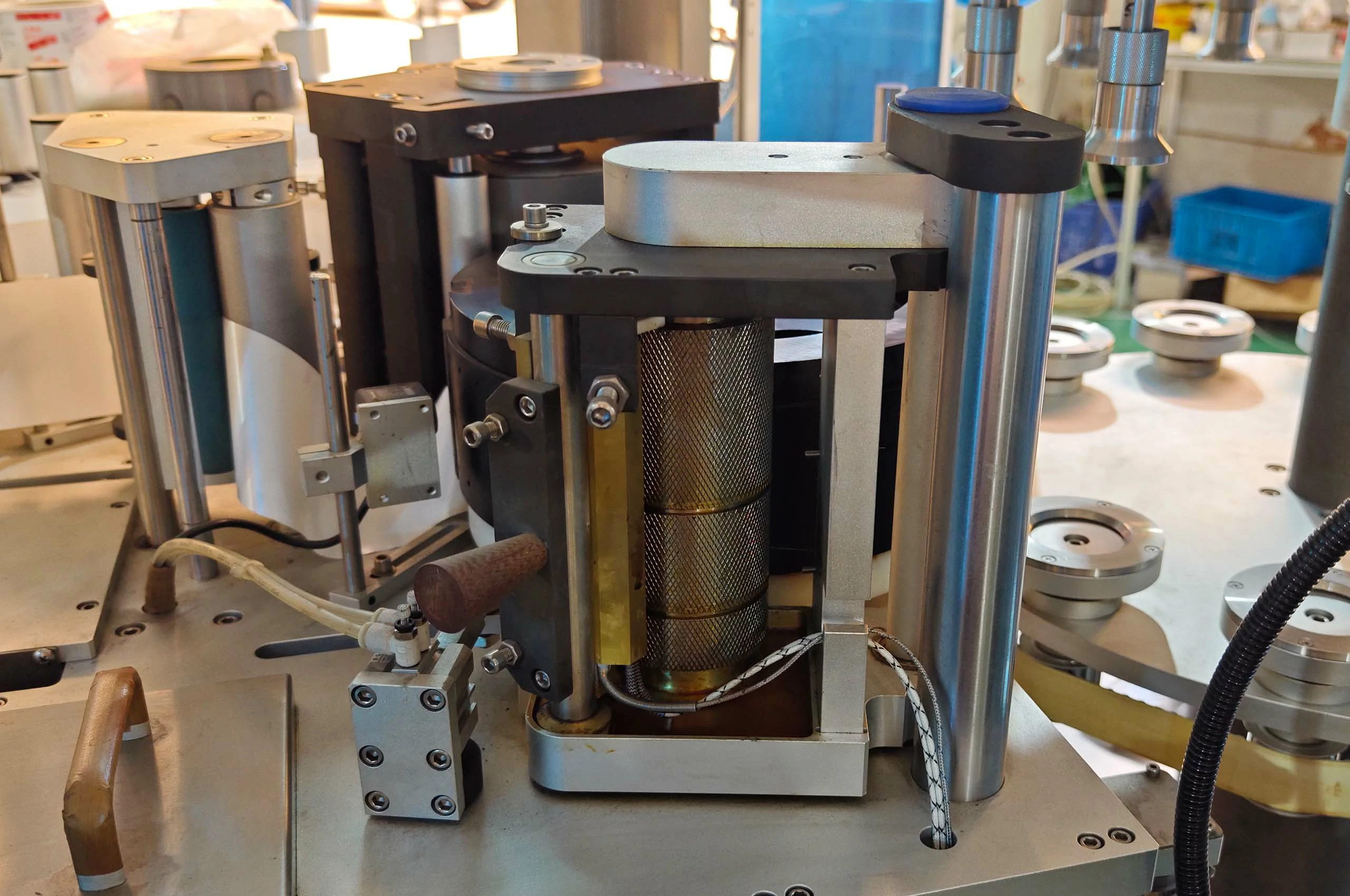

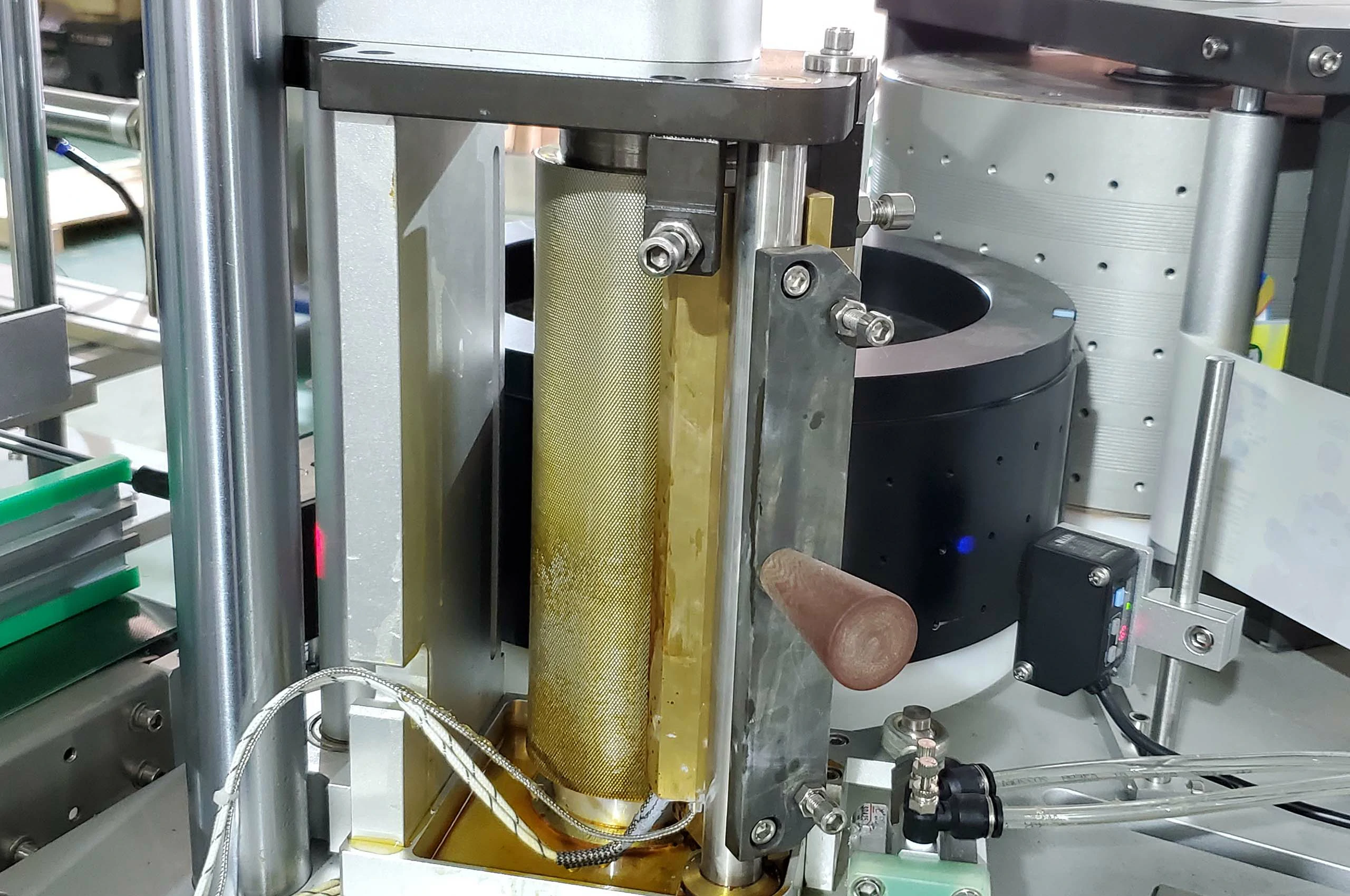

Hot Melt Cylinder

The hot melt cylinder melts and stores adhesive, maintaining a consistent flow of glue for precise label application.

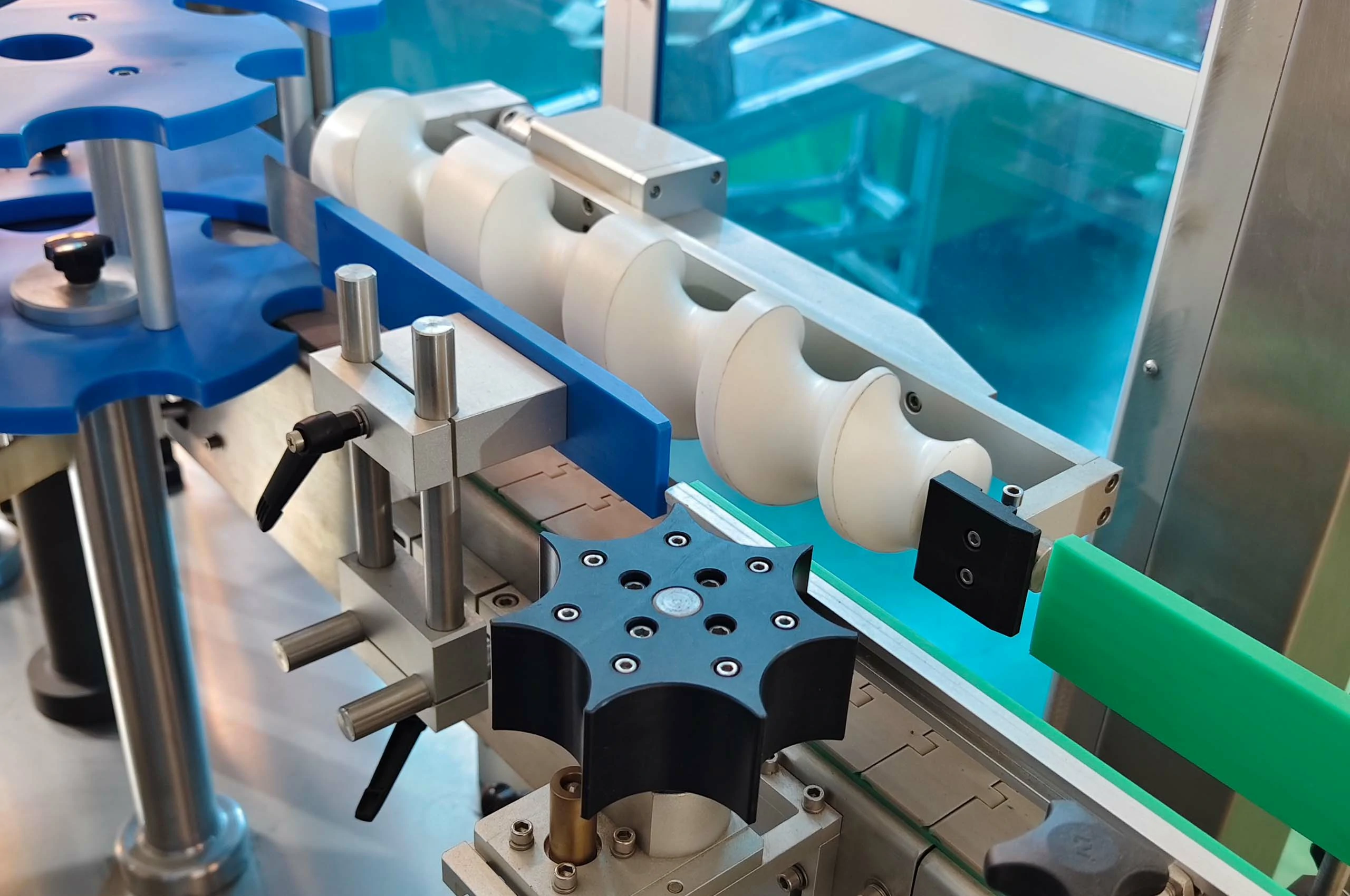

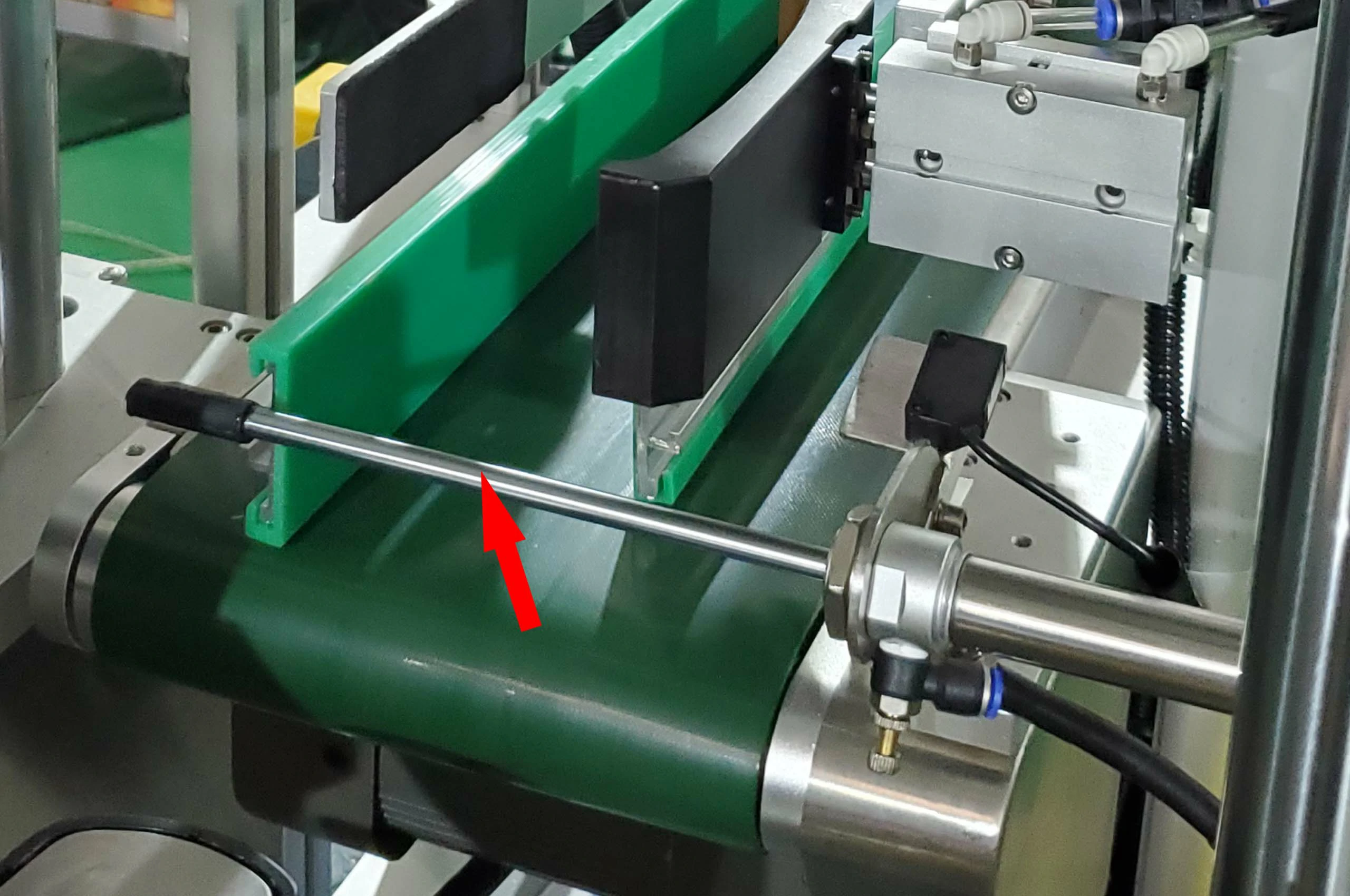

Bottle Feeding Screw

The bottle feeding screw ensures smooth and controlled transport of bottles into the labeling station.

Bottle Dividing Mechanism

The bottle dividing mechanism separates and spaces bottles accurately before they enter the labeling station.

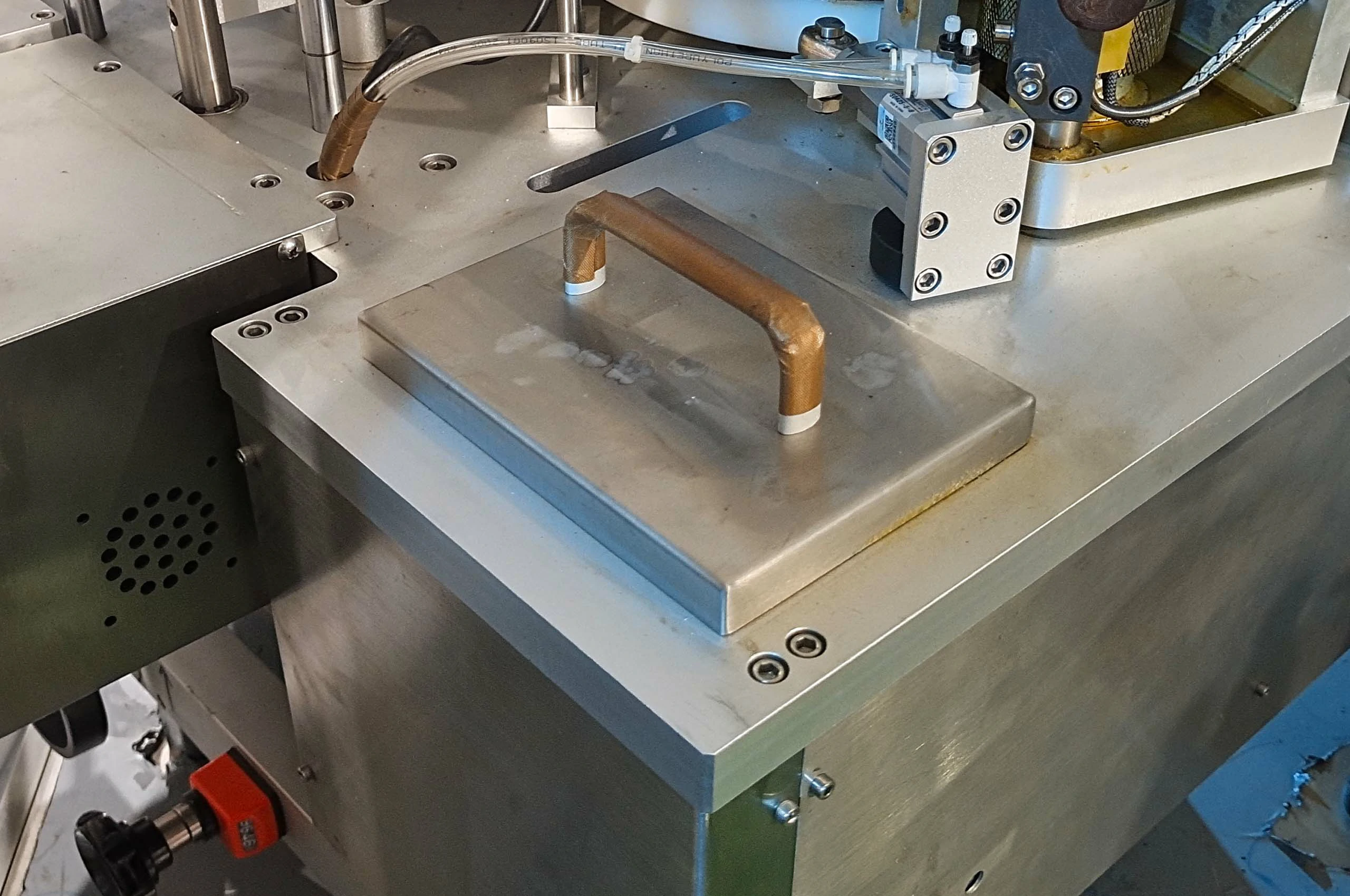

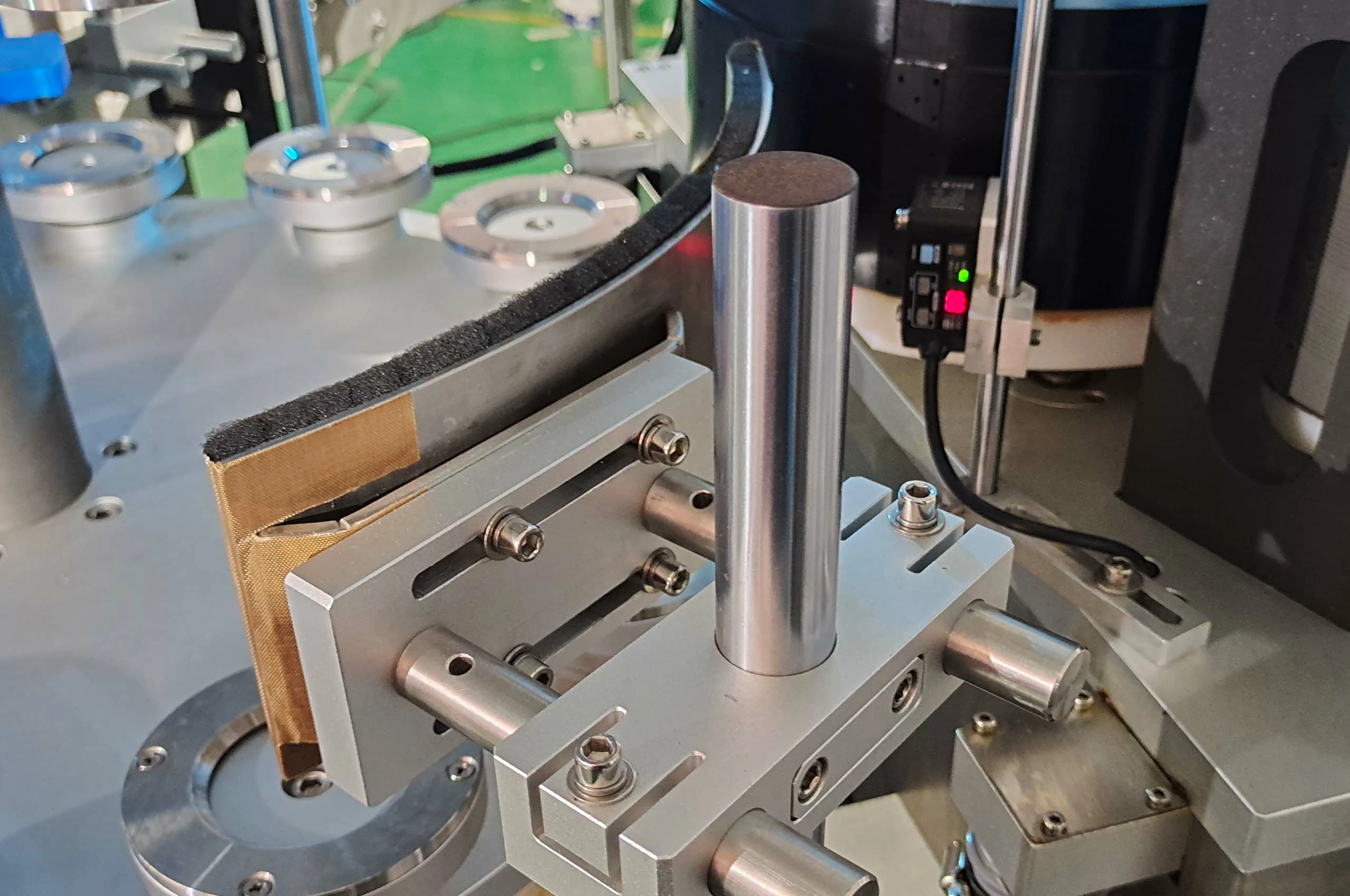

Pressing Device

The pressing device applies controlled pressure to ensure the label adheres securely to the bottle surface.

Device for Attaching Labels

The device for attaching labels precisely applies the label to the product using hot melt glue or pressure-sensitive adhesive.

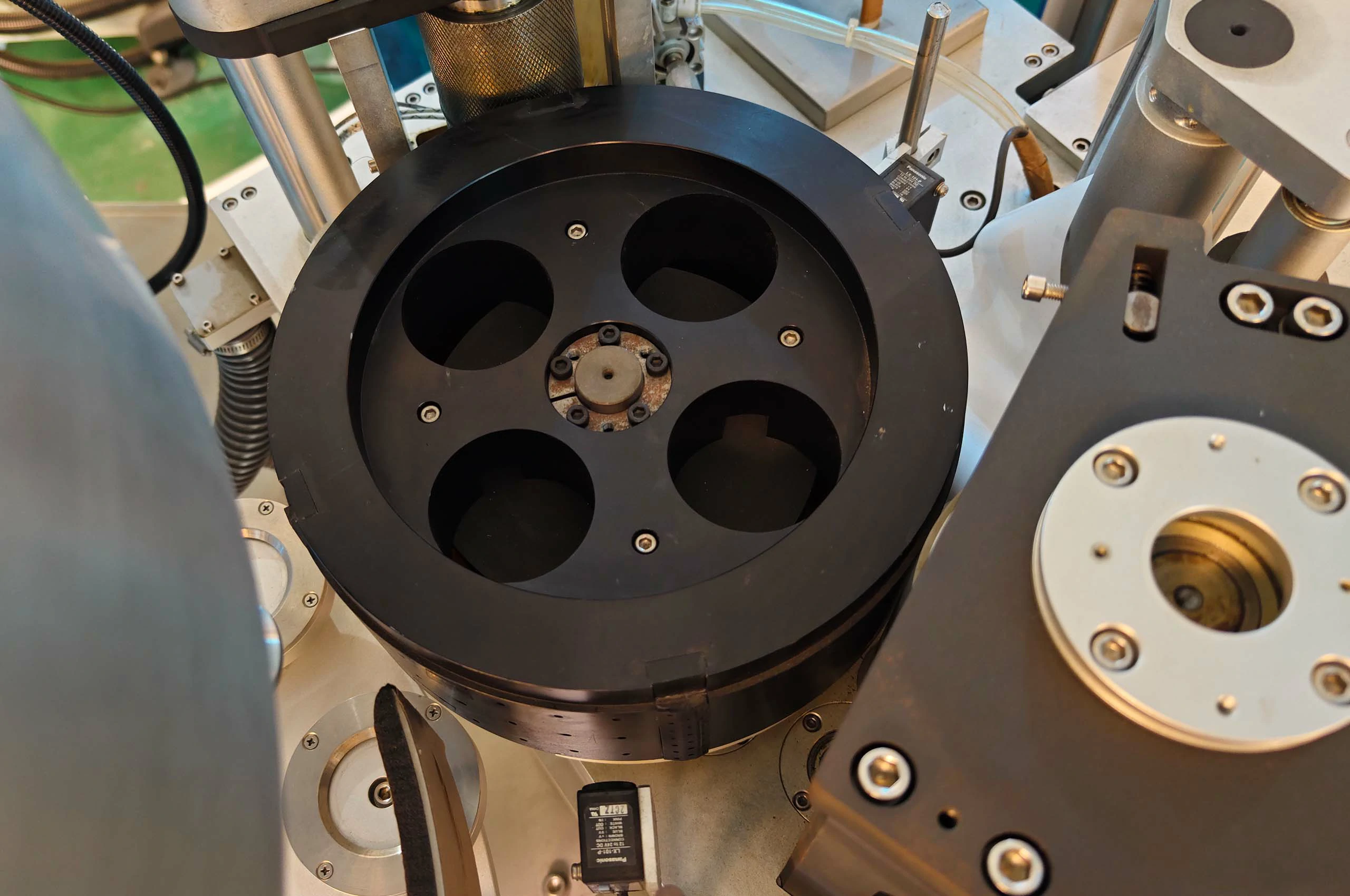

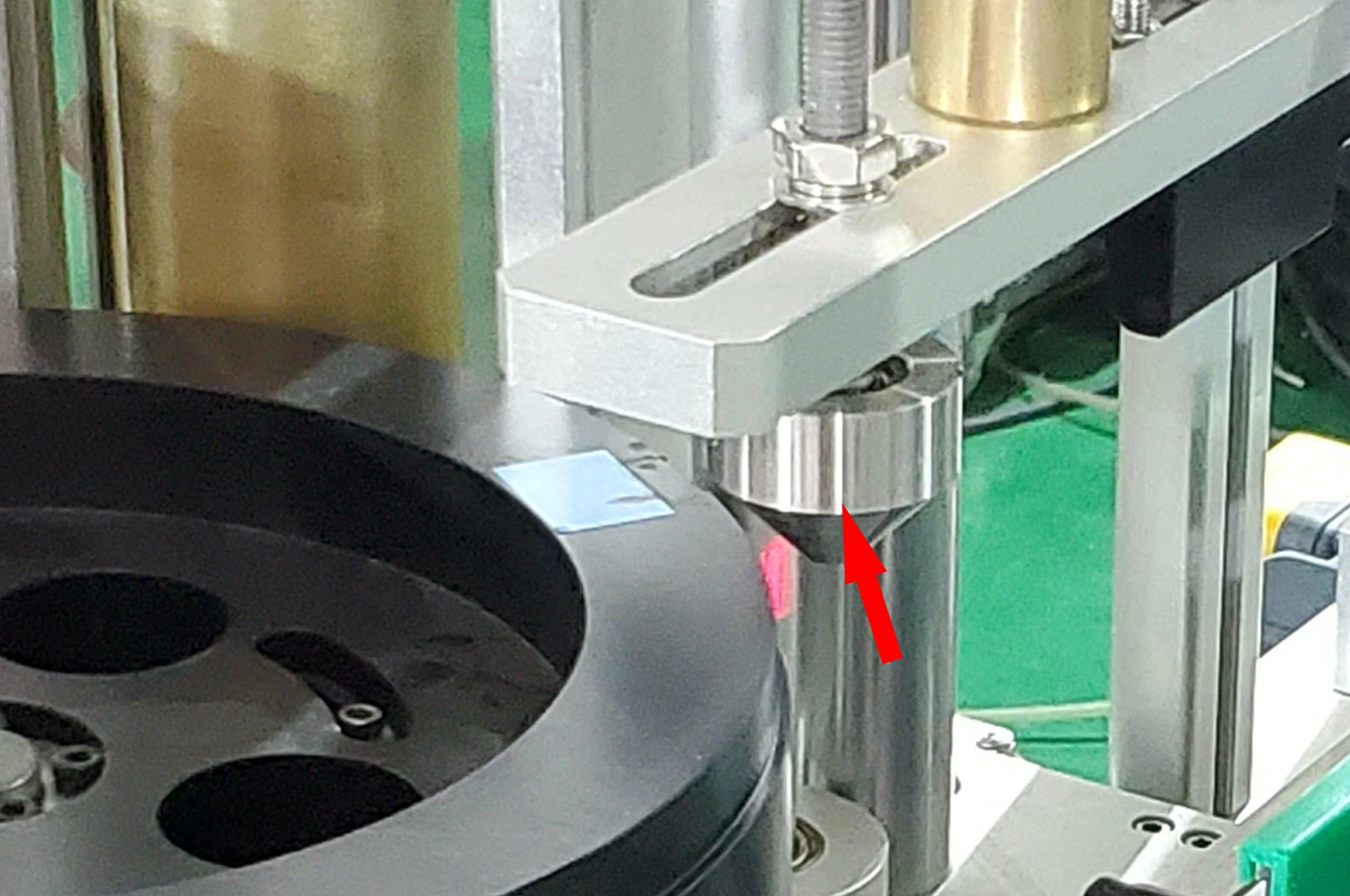

Labeling Drum

It rotates to smoothly transfer the label onto the bottle, ensuring precise positioning and consistent label application.

Gluing Roller

The gluing roller applies a uniform layer of hot melt adhesive to the label, ensuring even glue distribution at the ends of the label.

Filter

Used to remove any impurities or debris from the hot melt adhesive, ensuring a clean and smooth application of glue.

Touch Screen

It allows operators to easily adjust settings, such as labeling speed, temperature, and production parameters, ensuring efficient and user-friendly operation.

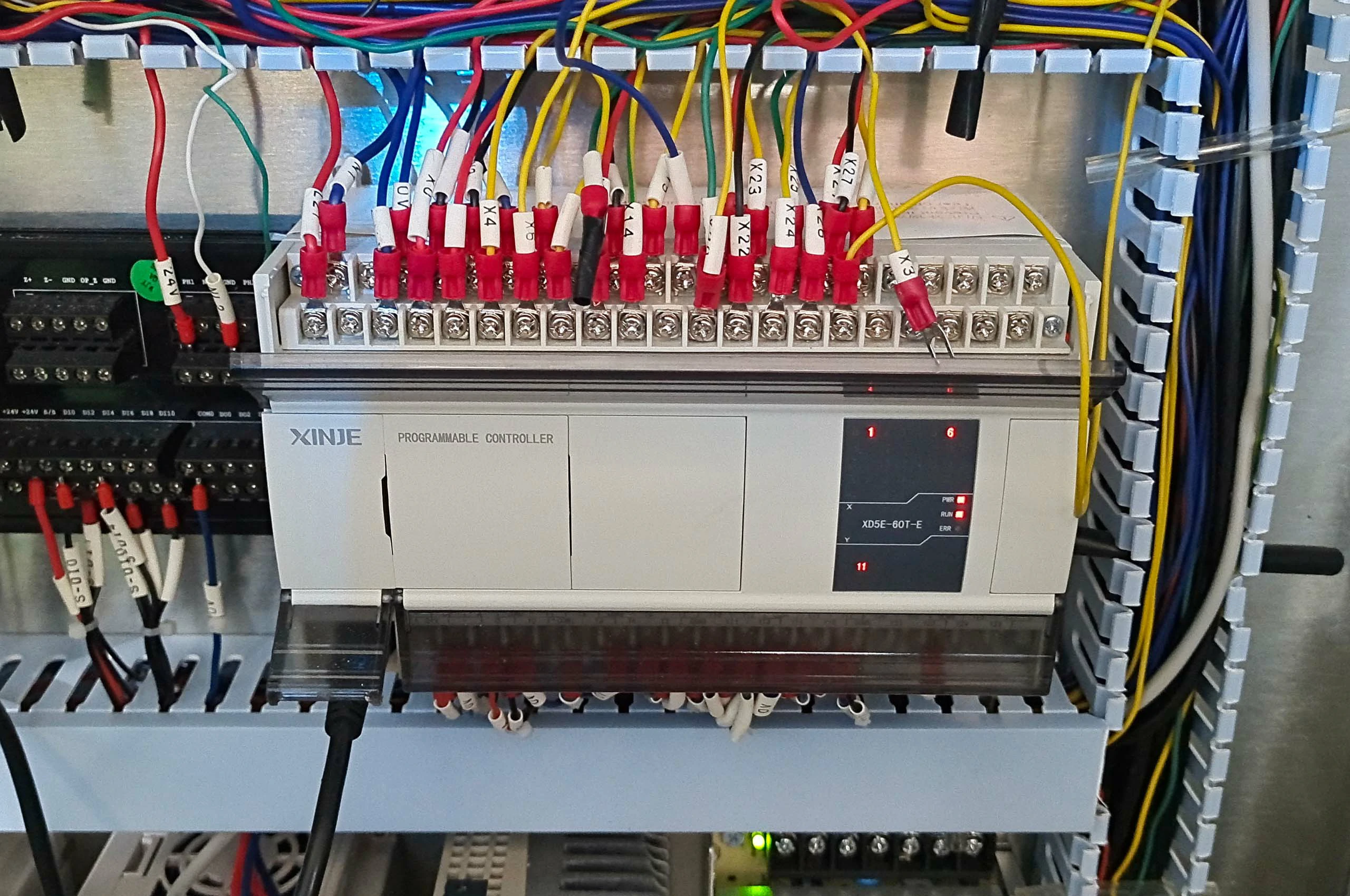

PLC

Ensuring precise operation and efficient coordination of components like speed, temperature, and labeling accuracy.

Frequency Converter

The frequency converter controls motor speed, enabling smooth and adjustable operation to meet production requirements.

Square Bottle Hot Melt Glue Labeling Machine

Label Roller

Pressing Device

Electric Cabinet

Touch Screen

Label Tray

Remote Control

The remote control system allows for easy and convenient operation of the labeling machine from a distance.

Sensitive Sensor

It ensures precise alignment and accurate label placement by automatically triggering the labeling process when a bottle is in the correct position.

Product Mold

Replace the product mold to be compatible with other bottle types.

Bottle Clamping Device

Hold the bottle firmly in place during labeling to prevent movement or misalignment.

Intercept

Stop or redirect products during production to ensure proper alignment or prevent problems such as kaka.

Bottle Pressing Device

Apply gentle pressure to secure the bottle. Ensure smooth and even label application.

Glue Application Roller

Apply the adhesive evenly to the label to ensure consistency and strong adhesion.

Knife Drum

Used to cut the label from the roll after applying it to the bottle, ensuring clean and precise label separation.

Labeling Drum

Guide the label by rotating the label smoothly onto the container.

Label Fastening Plate

Attach the label firmly to the bottle to prevent slipping or misalignment during the labeling process.

Label Fastening Plate

The label roller guides the label smoothly from the roll to the bottle, ensuring consistent movement and accurate application without wrinkles or jams.

Label Tray

The label tray holds and supports the label roll, ensuring smooth feeding of labels to the application system.

Can Be Used for Hundreds of Different Containers

Our hot melt glue labeling machines are versatile and designed to mark a variety of container shapes and sizes. It is easily adapted to different packaging needs, providing consistent, high quality labels across different product types.

Watch Our Hot Melt Glue Labeling Machine in Action!

See how our machine delivers fast, precise labeling for various containers with smooth and efficient operation.

Hot Melt Glue Labeling Machine FAQs

It can label round, square, and other container shapes such as bottles, jars, and cans.

It can handle OPP film labels, paper-plastic composite labels, and paper labels.

Yes, the machine typically comes with a one-year warranty covering manufacturing defects.

Contact us

If standard labeling machines don’t meet your needs, we can manufacture a custom labeling machine based on your production requirements!

Please take a moment to fill out the form on the right with some details about your product labeling needs, so our engineers can understand how to best assist you and provide tailored advice.

Get Your Labeling Machine Quote Here!

Please fill out this form to submit a request for quote(* denotes required fields)